PLASMA TORCH CONSUMABLE PARTS

During the cutting process, the parts on the end of the torch are slowly consumed. To prevent premature consumption of some torch parts and to prevent damage to the torch itself, it is necessary to replace the consumable parts in a timely manner. When the cutting arc seems to be weaker than normal or sputters, inspect all torch consumables for wear and damage and replace as needed.

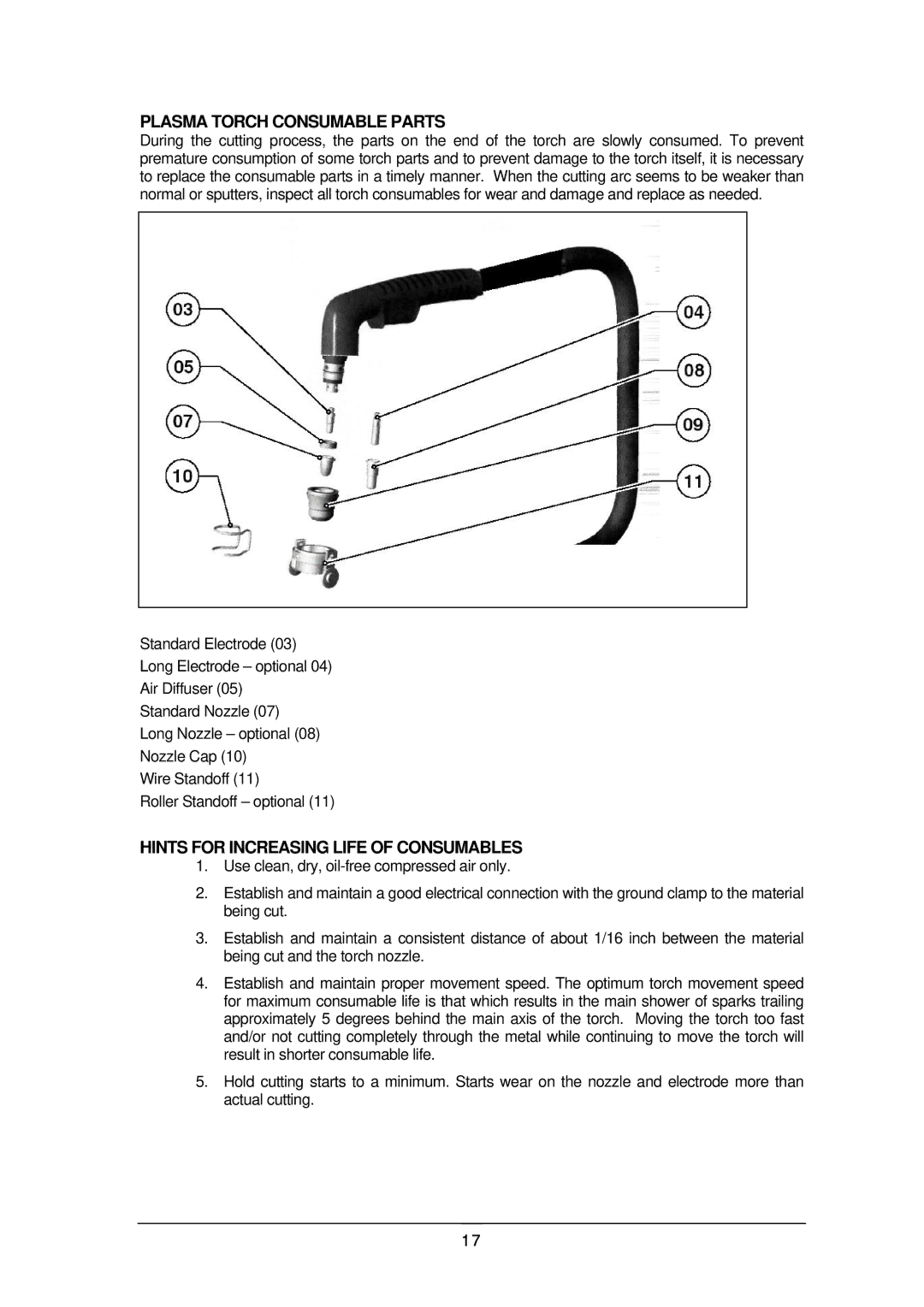

Standard Electrode (03)

Long Electrode – optional 04)

Air Diffuser (05)

Standard Nozzle (07)

Long Nozzle – optional (08)

Nozzle Cap (10)

Wire Standoff (11)

Roller Standoff – optional (11)

HINTS FOR INCREASING LIFE OF CONSUMABLES

1.Use clean, dry,

2.Establish and maintain a good electrical connection with the ground clamp to the material being cut.

3.Establish and maintain a consistent distance of about 1/16 inch between the material being cut and the torch nozzle.

4.Establish and maintain proper movement speed. The optimum torch movement speed for maximum consumable life is that which results in the main shower of sparks trailing approximately 5 degrees behind the main axis of the torch. Moving the torch too fast and/or not cutting completely through the metal while continuing to move the torch will result in shorter consumable life.

5.Hold cutting starts to a minimum. Starts wear on the nozzle and electrode more than actual cutting.

17