G. | CIRCUIT BREAKER |

This battery charger is equipped with a

NOTE: Clicking sound is normal. Wait until charger automati- cally resets itself.

CAUTION: Persistent clicking (more than 30 minutes) may indi- cate reverse connection or shorted battery cells. (See TROUBLE SHOOTING.)

H. | BATTERY TYPES |

Three basic types of

Conventional and Low Maintenance Batteries. These are the antimony/lead batteries. Conventional/low maintenance batter- ies require periodic addition of water to the acid solution (elec- trolyte). Additional water may be added by removing the filler caps located on the top of the battery.

When antimony is known to be one of the materials used in the battery's construction, that battery is a low maintenance/conven- tional type.

CAUTION: Some low maintenance batteries have a relatively smooth top without any apparent battery filler caps. If, however, the battery manufacturer/distributor recommends periodic check-

ing of electrolyte level and provides access to the battery for water additions, the battery is probably a low maintenance/con- ventional type.

I.OPERATING INSTRUCTIONS: CHARGING BATTERY IN VEHICLE

When charging battery in the vehicle, take care to determine the battery type and which post is grounded. To reduce risk of a spark near battery, follow these steps when battery is installed in vehicle. WARNING: A spark near battery may cause battery explosion.

With the

1.Position AC power cord and DC charging cords to reduce risk of damage by hood, door, or moving engine parts.

2.Stay clear of fan blades, belts, pulleys, and other parts that can cause injury.

3.Check polarity of battery posts. Battery case will be marked by each post: POSITIVE (POS, P, +) and NEGATIVE (NEG, N,

4.Determine which post of battery is ground (connected to chassis).

NOTE: The negative post is normally grounded.

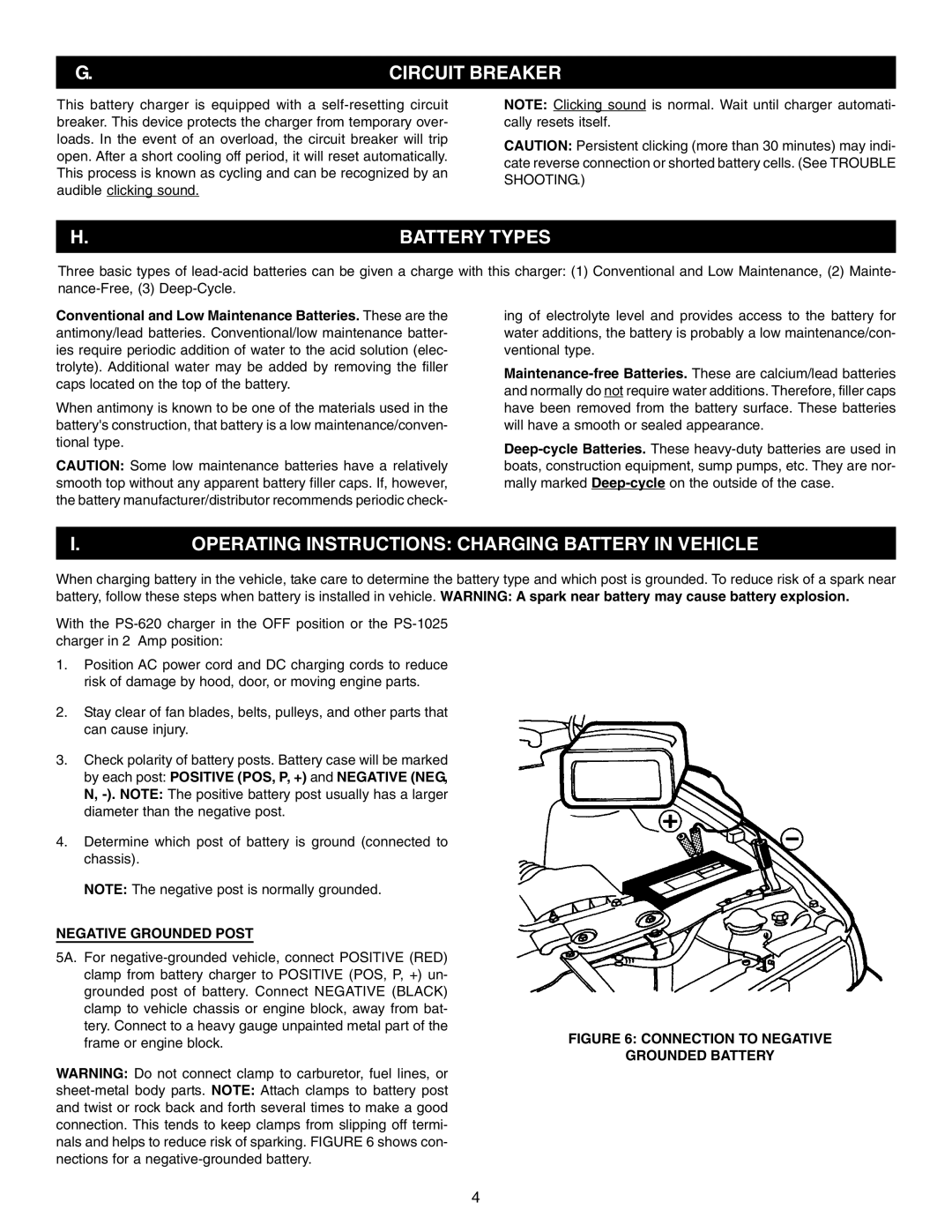

NEGATIVE GROUNDED POST

5A. For

WARNING: Do not connect clamp to carburetor, fuel lines, or

FIGURE 6: CONNECTION TO NEGATIVE

GROUNDED BATTERY

4