3.3Mounting considerations

•Use an elastic mounting material to protect drives so as to ensure that more shock can be absorbed.

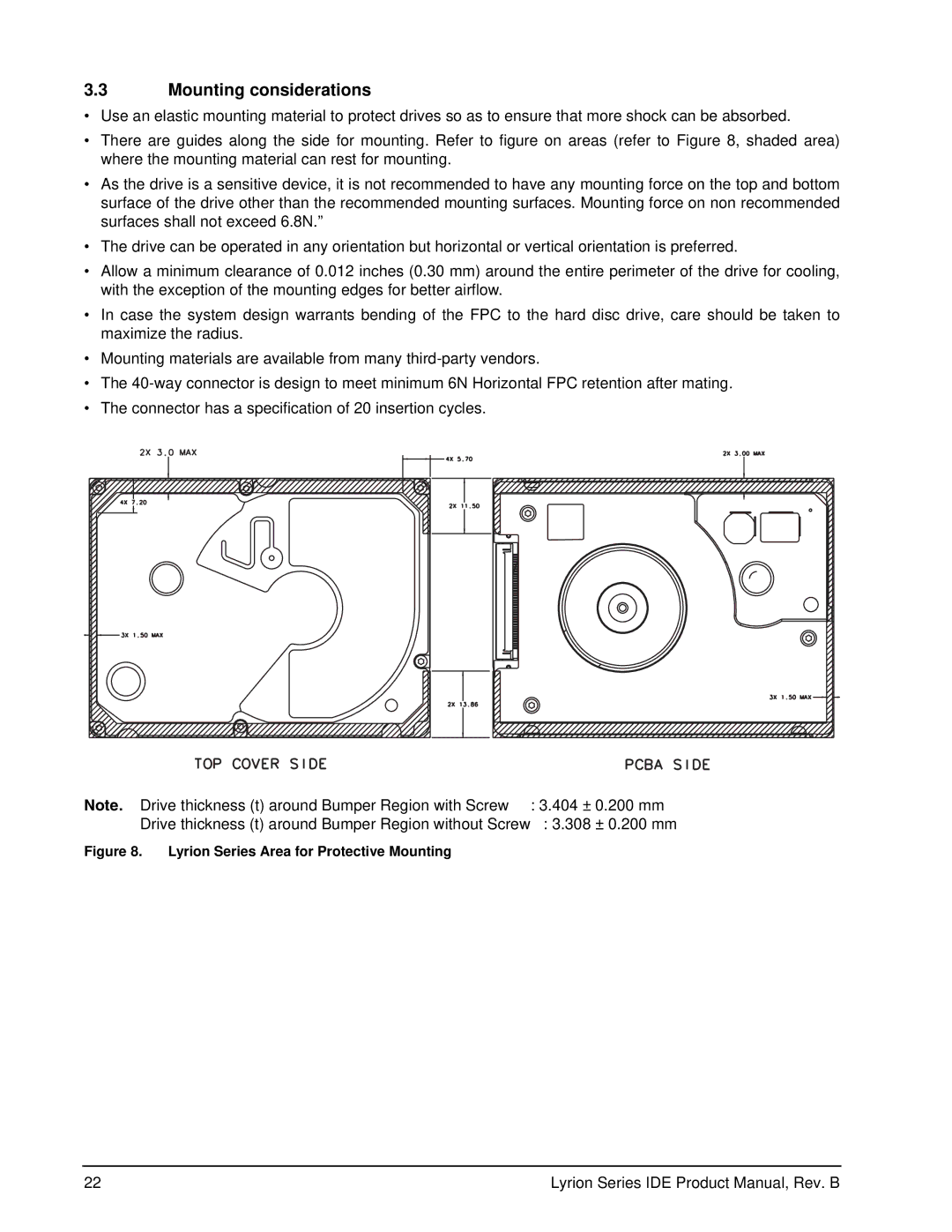

•There are guides along the side for mounting. Refer to figure on areas (refer to Figure 8, shaded area) where the mounting material can rest for mounting.

•As the drive is a sensitive device, it is not recommended to have any mounting force on the top and bottom surface of the drive other than the recommended mounting surfaces. Mounting force on non recommended surfaces shall not exceed 6.8N.”

•The drive can be operated in any orientation but horizontal or vertical orientation is preferred.

•Allow a minimum clearance of 0.012 inches (0.30 mm) around the entire perimeter of the drive for cooling, with the exception of the mounting edges for better airflow.

•In case the system design warrants bending of the FPC to the hard disc drive, care should be taken to maximize the radius.

•Mounting materials are available from many

•The

•The connector has a specification of 20 insertion cycles.

Note. Drive thickness (t) around Bumper Region with Screw | : 3.404 ± | 0.200 mm |

Drive thickness (t) around Bumper Region without Screw | : 3.308 | ± 0.200 mm |

Figure 8. Lyrion Series Area for Protective Mounting

22 | Lyrion Series IDE Product Manual, Rev. B |