44Ultra Laminator, SM110EN specifications

The SEAL SM110EN,44 Ultra Laminator is a state-of-the-art finishing device designed specifically for professionals in the graphics and printing industries. This high-quality laminator streamlines the lamination process, providing exceptional results for a wide range of applications, including signage, photography, packaging, and other graphic projects.One of the standout features of the SM110EN,44 is its impressive working width of 44 inches, which allows users to laminate larger projects with ease. This makes it an ideal choice for businesses that require efficiency in processing large prints or multiple smaller items in one go. The laminator is compatible with various film types, including thermal, pressure-sensitive, and adhesive laminates, providing versatility to cater to different project requirements.

The SM110EN,44 utilizes advanced technology to ensure consistent and high-quality lamination results. It features a user-friendly interface with intuitive controls, which allows for quick and easy adjustments to settings such as temperature, speed, and pressure. The digital temperature control ensures that the heating element maintains an even temperature across the entire width of the laminating film, thereby preventing uneven lamination, bubbles, or other defects.

Another significant advantage of the SM110EN,44 is its dual roller system, which facilitates the smooth and efficient passage of materials through the laminator. The rollers are designed to provide even pressure, reducing the risk of warping and ensuring that each print is finished to perfection. The machine also incorporates a self-advancing film system, making it easier to load and change rolls quickly, thereby reducing downtime.

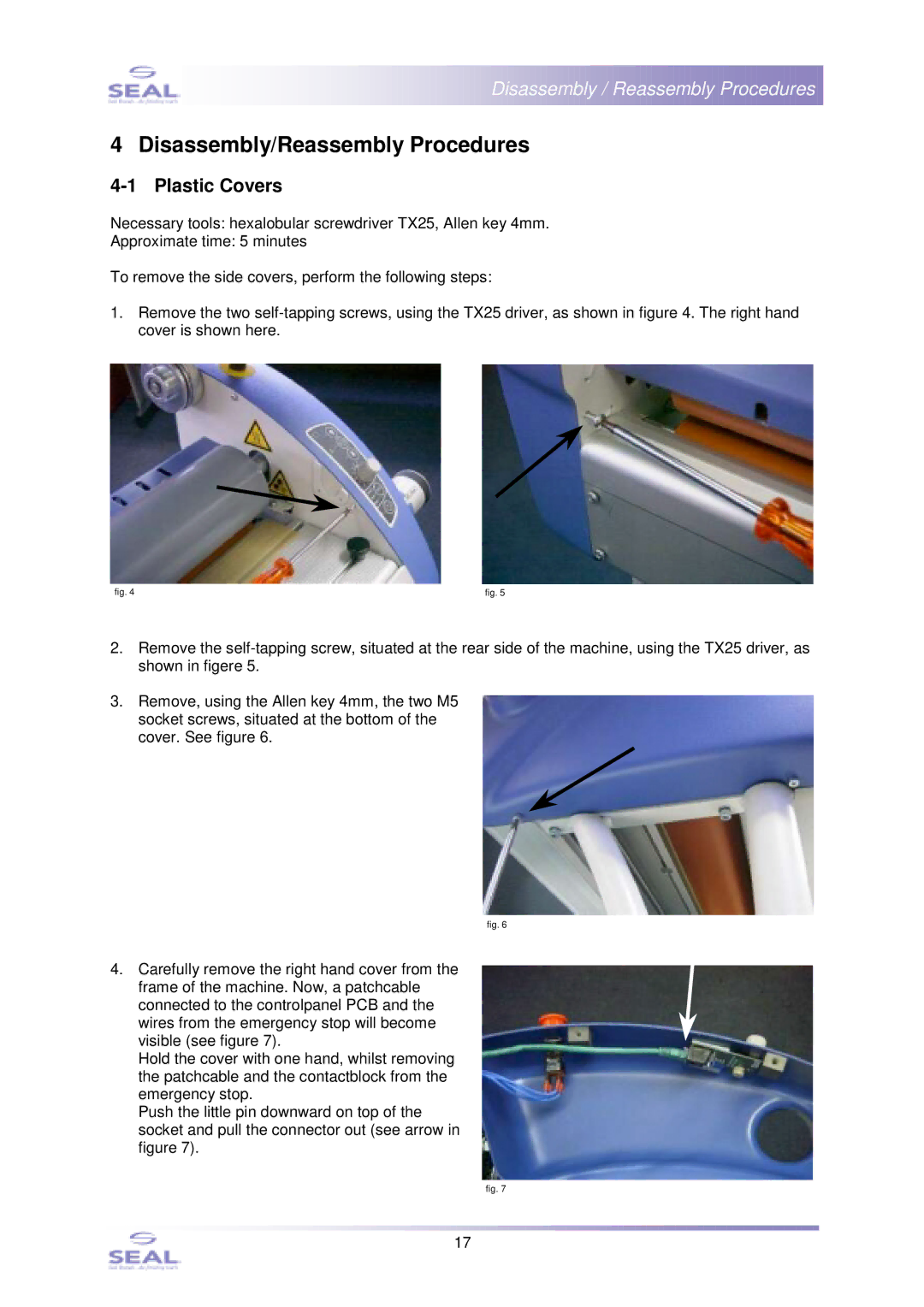

Equipped with safety features, the SEAL SM110EN,44 ensures a secure working environment. This includes emergency stop buttons and protective covers, giving operators peace of mind while using high-speed equipment. Its sturdy design and durable construction mean that it can withstand the rigors of frequent use in a busy production environment.

The SEAL SM110EN,44 Ultra Laminator is a powerful tool that elevates the quality and efficiency of lamination processes. With its advanced features, robust design, and user-friendly controls, it serves as an indispensable asset for any professional looking to enhance their finishing capabilities and produce high-quality results in their graphic projects. Whether it's for small-scale applications or large production runs, the SM110EN,44 stands out as a reliable choice in the laminating market.