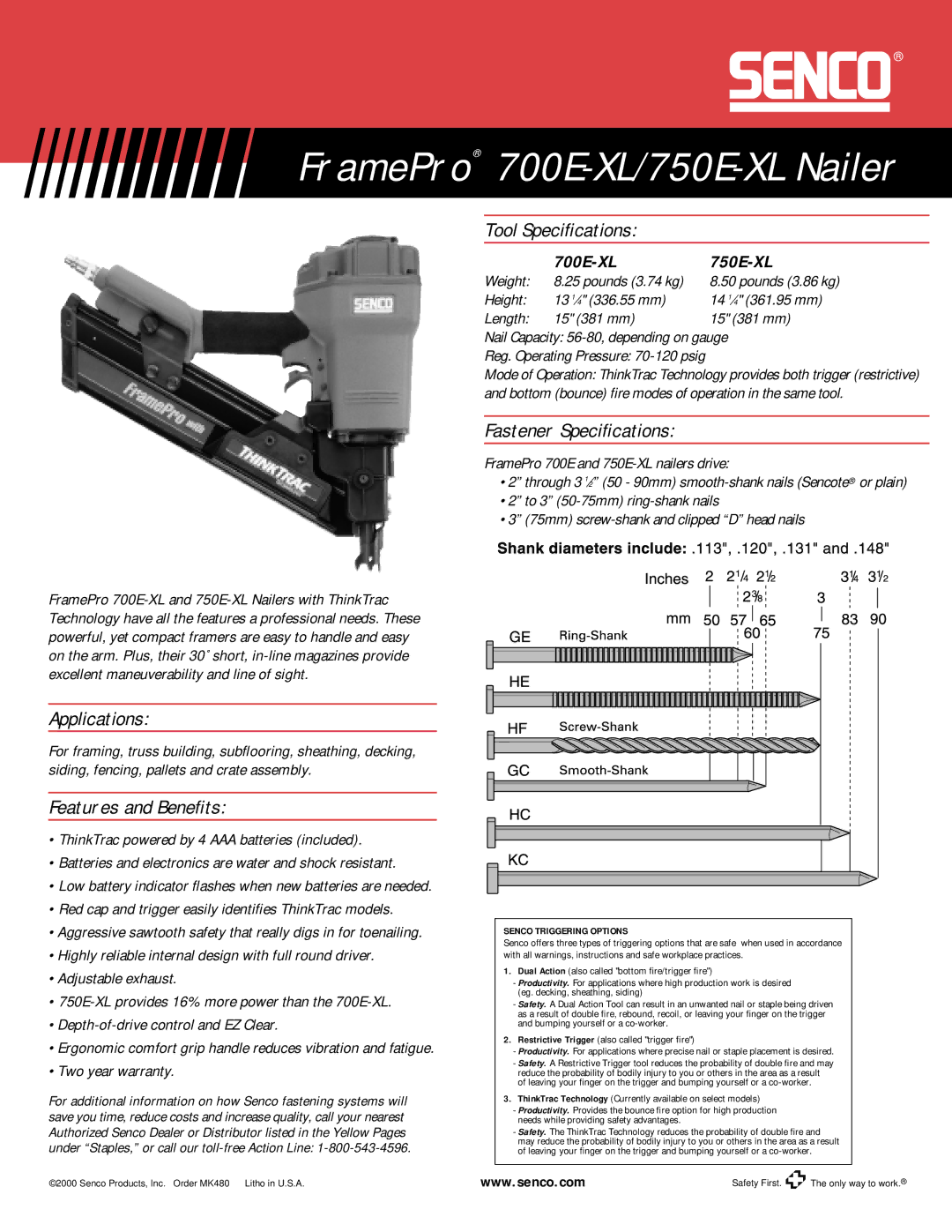

750E-XL, 700E-XL specifications

The Senco 700E-XL and 750E-XL are advanced pneumatic tools designed for professional contractors and construction professionals who demand high performance and versatility. These models are well-regarded for their robust construction, intuitive design, and user-friendly features, making them ideal for a wide range of applications from framing to finishing.One of the standout features of the Senco 700E-XL is its exceptional drive power and accuracy. It is engineered to deliver consistent nailing depth, ensuring that every fastener is driven to the correct level. This precision is critical in both structural and aesthetic applications where appearance and functionality are key. Meanwhile, the 750E-XL provides an upgraded performance with increased power and capability, making it suitable for more demanding projects.

Both models utilize Senco’s innovative air technology, which minimizes air consumption without sacrificing power. This technology not only leads to lower operating costs but also contributes to a lighter, more manageable tool. Additionally, the high-efficiency motor design enhances the overall performance, allowing users to complete tasks more quickly and with less fatigue.

Another notable characteristic of the Senco 700E-XL and 750E-XL is their ergonomic design. Each tool features a comfortable grip that reduces hand strain during prolonged use, ensuring that professionals can work efficiently throughout the day. The weight distribution of these tools has been meticulously optimized, allowing for better balance and control during operation.

Both the 700E-XL and 750E-XL are equipped with a durable magazine that can hold a significant number of fasteners. This feature minimizes downtime for reloading, ultimately increasing productivity on job sites. Additionally, they are designed with jam-clear technology, which makes clearing any obstructions quick and straightforward – a critical feature for maintaining workflow.

The versatility of these tools is further enhanced by their adaptability to various fastener types, ranging from standard framing nails to high-quality finishing nails. This capability makes the Senco 700E-XL and 750E-XL valuable additions to any contractor's toolkit.

In conclusion, the Senco 700E-XL and 750E-XL are exemplary choices for professionals seeking powerful, efficient, and user-friendly pneumatic tools. Their blend of innovative technology, ergonomic design, and versatile performance sets them apart in the competitive market of construction equipment. Whether you are framing a house or completing detailed finish work, these tools deliver the reliability and effectiveness needed to get the job done right.