OPERATION

PRE-START CHECKLIST:

1. Check oil level. Add if necessary.

2. Remove any moisture in the air compressor air tank. Remove excessive pressure with an air tool, then open the air tank drain valve in the bottom of the air tank. Close tightly when drained.

WARNING

Risk of bodily injury. NEVER attempt to open the drain valve when more than 10 PSI of air pressure is in the air tank!

3.Make sure the engine switch is in the "OFF" position.

4.Make sure all safety valves are working correctly.

5.Make sure all guards and covers are in place and securely mounted.

1. Flip the toggle on top of the pilot valve to the upright position. This provides a loadless start. The air compressor will unload and allow the engine to start easier.

2. Start the engine. (Refer to the Engine Manual accompanying this unit.)

3. When the engine has run for

4. Set pressure by adjusting the pressure regulator knob counterclockwise for less pressure and clockwise for more pressure.

5. If you notice any unusual noise or vibration, stop the air compressor and refer to "Troubleshooting".

SHUTDOWN:

1. To stop the air compressor, move the engine switch to the "Off" position. (Refer to the Engine Manual accompanying this unit.)

2. Drain air from the air tanks by releasing air with an attached air tool or by pulling on the safety relief valve rings.

3. Once pressure in the air tanks register under 10 pounds, open the drain valve under each air tank to drain any moisture.

4. Allow the air compressor to cool down.

5. Wipe air compressor clean and store in a safe,

MAINTENANCE

Read the instruction manual before performing maintenance. The following procedures must be performed when stopping the air compressor for maintenance or service.

1. Turn off air compressor.

2. Open all drains.

3. Wait for the air compressor to cool before starting service.

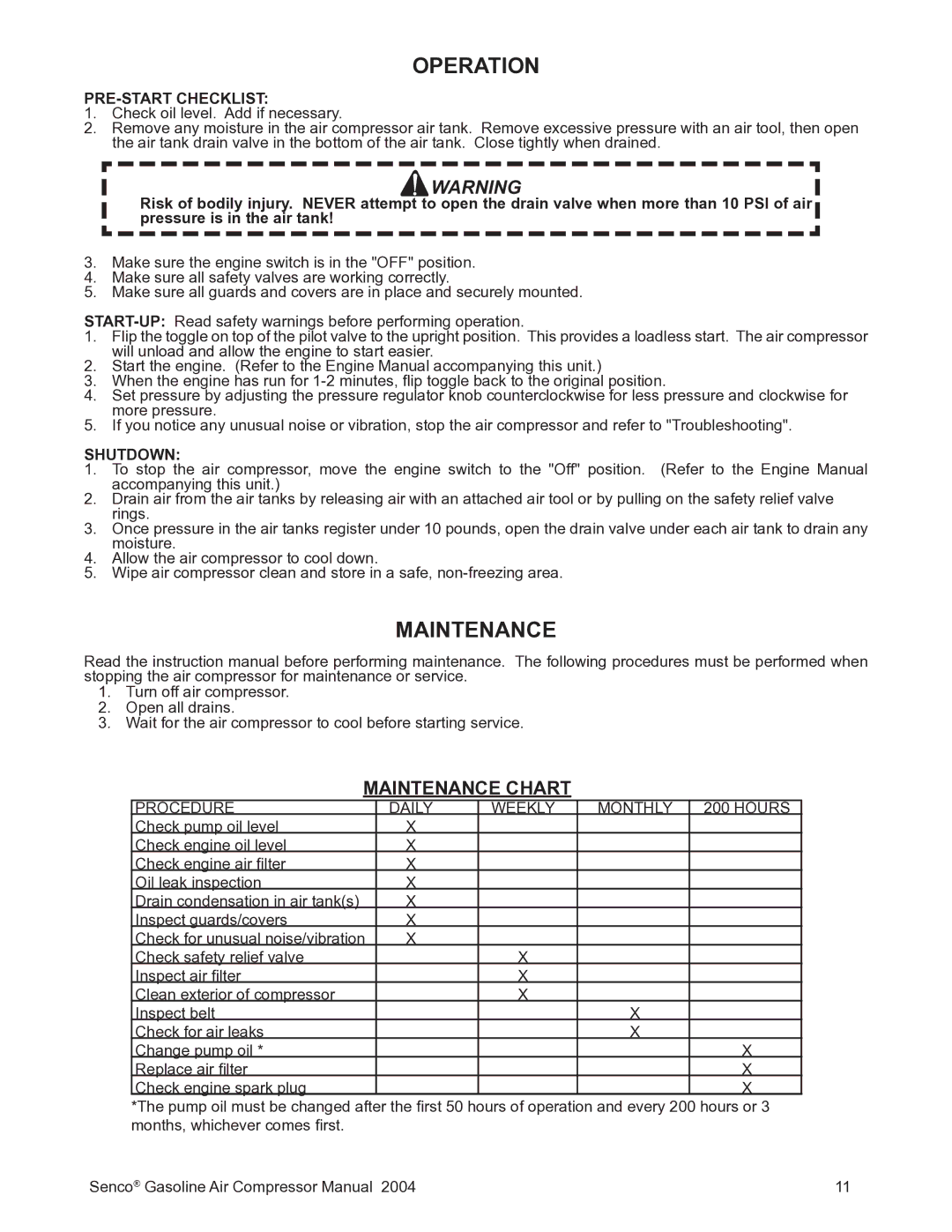

MAINTENANCE CHART

|

|

|

|

|

PROCEDURE | DAILY | WEEKLY | MONTHLY | 200 HOURS |

Check pump oil level | X |

|

|

|

Check engine oil level | X |

|

|

|

Check engine air filter | X |

|

|

|

Oil leak inspection | X |

|

|

|

Drain condensation in air tank(s) | X |

|

|

|

Inspect guards/covers | X |

|

|

|

Check for unusual noise/vibration | X |

|

|

|

Check safety relief valve |

| X |

|

|

Inspect air filter |

| X |

|

|

Clean exterior of compressor |

| X |

|

|

Inspect belt |

|

| X |

|

Check for air leaks |

|

| X |

|

Change pump oil * |

|

|

| X |

Replace air filter |

|

|

| X |

Check engine spark plug |

|

|

| X |

*The pump oil must be changed after the first 50 hours of operation and every 200 hours or 3 months, whichever comes first.

Senco® Gasoline Air Compressor Manual 2004 | 11 |