Description

DigiFloor is an electronic thermostat for the regulation of floor heating. Mounting is done via a connection box. The thermostat is controlled wirelessly by the DigiHeat control unit. Time base for switching of load is 20 minutes.

DigiFloor must be installed by an authorized electrician.

If the floor sensor is not connected, the thermostat will use an internal air sensor for the regulation of room temperature (5-30°C). When the floor sensor is connected switching times are operational according to floor temperature. When the floor sensor is used the setpoint temperature should be considered as a guide figure only. Start off with a setpoint temperature of 20°C and adjust setpoint temperature until floor temperature is at your comfort level. NOTE! It takes hours for the floor temperature to stabilize.

It is possible to use both the internal air sensor and floor sensor. The internal air sensor will regulate room temperature, while the floor sensor will limit the floor temperature to a maximum of 27°C. See paragraph sensor alternatives for details.

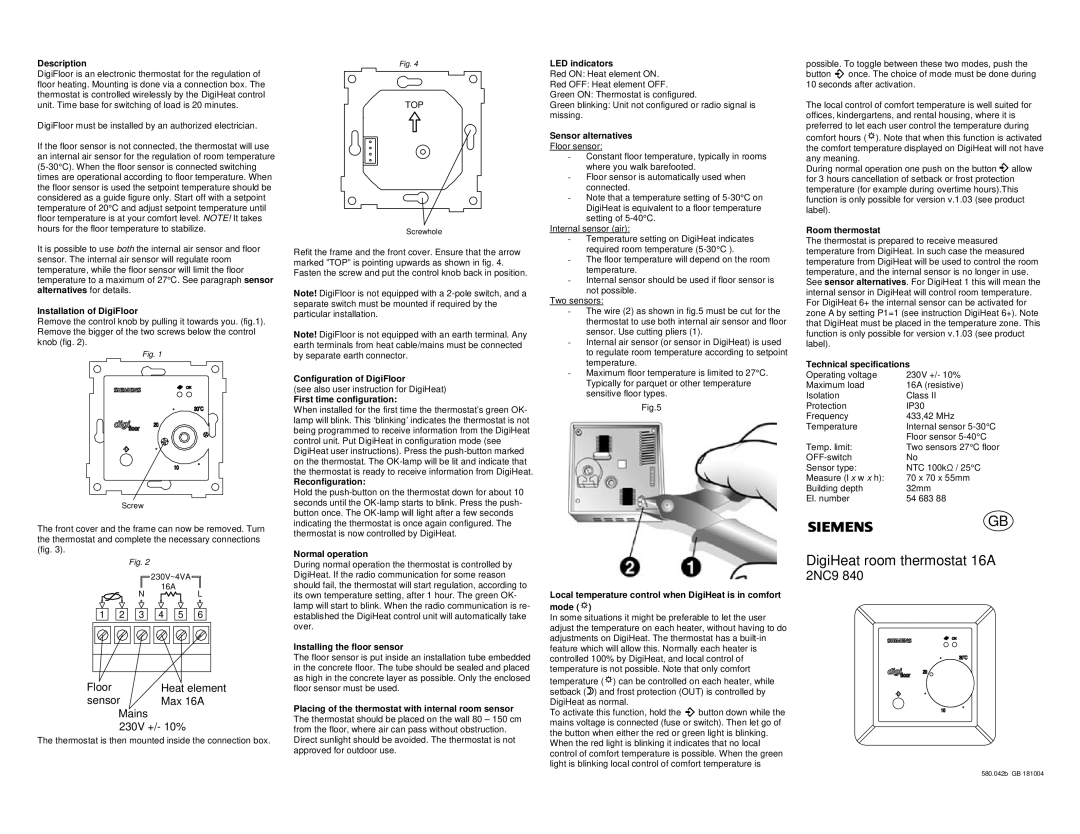

Installation of DigiFloor

Remove the control knob by pulling it towards you. (fig.1). Remove the bigger of the two screws below the control knob (fig. 2).

Fig. 1

Screw

The front cover and the frame can now be removed. Turn the thermostat and complete the necessary connections (fig. 3).

Fig. 2

Floor | Heat element |

sensor | Max 16A |

Mains | |

230V +/- 10%

The thermostat is then mounted inside the connection box.

Fig. 4

TOP

Screwhole

Refit the frame and the front cover. Ensure that the arrow marked ”TOP” is pointing upwards as shown in fig. 4. Fasten the screw and put the control knob back in position.

Note! DigiFloor is not equipped with a 2-pole switch, and a separate switch must be mounted if required by the particular installation.

Note! DigiFloor is not equipped with an earth terminal. Any earth terminals from heat cable/mains must be connected by separate earth connector.

Configuration of DigiFloor

(see also user instruction for DigiHeat)

First time configuration:

When installed for the first time the thermostat’s green OK- lamp will blink. This ‘blinking’ indicates the thermostat is not being programmed to receive information from the DigiHeat control unit. Put DigiHeat in configuration mode (see DigiHeat user instructions). Press the push-button marked on the thermostat. The OK-lamp will be lit and indicate that the thermostat is ready to receive information from DigiHeat.

Reconfiguration:

Hold the push-button on the thermostat down for about 10 seconds until the OK-lamp starts to blink. Press the push- button once. The OK-lamp will light after a few seconds indicating the thermostat is once again configured. The thermostat is now controlled by DigiHeat.

Normal operation

During normal operation the thermostat is controlled by DigiHeat. If the radio communication for some reason should fail, the thermostat will start regulation, according to its own temperature setting, after 1 hour. The green OK- lamp will start to blink. When the radio communication is re- established the DigiHeat control unit will automatically take over.

Installing the floor sensor

The floor sensor is put inside an installation tube embedded in the concrete floor. The tube should be sealed and placed as high in the concrete layer as possible. Only the enclosed floor sensor must be used.

Placing of the thermostat with internal room sensor

The thermostat should be placed on the wall 80 – 150 cm from the floor, where air can pass without obstruction. Direct sunlight should be avoided. The thermostat is not approved for outdoor use.

LED indicators

Red ON: Heat element ON.

Red OFF: Heat element OFF.

Green ON: Thermostat is configured.

Green blinking: Unit not configured or radio signal is missing.

Sensor alternatives

Floor sensor:

-Constant floor temperature, typically in rooms where you walk barefooted.

-Floor sensor is automatically used when connected.

-Note that a temperature setting of 5-30°C on

DigiHeat is equivalent to a floor temperature setting of 5-40°C.

Internal sensor (air):

-Temperature setting on DigiHeat indicates required room temperature (5-30°C ).

-The floor temperature will depend on the room temperature.

-Internal sensor should be used if floor sensor is not possible.

Two sensors:

-The wire (2) as shown in fig.5 must be cut for the thermostat to use both internal air sensor and floor sensor. Use cutting pliers (1).

-Internal air sensor (or sensor in DigiHeat) is used to regulate room temperature according to setpoint temperature.

-Maximum floor temperature is limited to 27°C. Typically for parquet or other temperature sensitive floor types.

Fig.5

Local temperature control when DigiHeat is in comfort mode (

)

)

In some situations it might be preferable to let the user adjust the temperature on each heater, without having to do adjustments on DigiHeat. The thermostat has a built-in feature which will allow this. Normally each heater is controlled 100% by DigiHeat, and local control of temperature is not possible. Note that only comfort

temperature (

) can be controlled on each heater, while setback (

) can be controlled on each heater, while setback (

) and frost protection (OUT) is controlled by DigiHeat as normal.

) and frost protection (OUT) is controlled by DigiHeat as normal.

To activate this function, hold the  button down while the mains voltage is connected (fuse or switch). Then let go of the button when either the red or green light is blinking.

button down while the mains voltage is connected (fuse or switch). Then let go of the button when either the red or green light is blinking.

When the red light is blinking it indicates that no local control of comfort temperature is possible. When the green light is blinking local control of comfort temperature is

possible. To toggle between these two modes, push the button  once. The choice of mode must be done during 10 seconds after activation.

once. The choice of mode must be done during 10 seconds after activation.

The local control of comfort temperature is well suited for offices, kindergartens, and rental housing, where it is preferred to let each user control the temperature during comfort hours (

). Note that when this function is activated the comfort temperature displayed on DigiHeat will not have any meaning.

). Note that when this function is activated the comfort temperature displayed on DigiHeat will not have any meaning.

During normal operation one push on the button  allow for 3 hours cancellation of setback or frost protection temperature (for example during overtime hours).This function is only possible for version v.1.03 (see product label).

allow for 3 hours cancellation of setback or frost protection temperature (for example during overtime hours).This function is only possible for version v.1.03 (see product label).

Room thermostat

The thermostat is prepared to receive measured temperature from DigiHeat. In such case the measured temperature from DigiHeat will be used to control the room temperature, and the internal sensor is no longer in use. See sensor alternatives. For DigiHeat 1 this will mean the internal sensor in DigiHeat will control room temperature. For DigiHeat 6+ the internal sensor can be activated for zone A by setting P1=1 (see instruction DigiHeat 6+). Note that DigiHeat must be placed in the temperature zone. This function is only possible for version v.1.03 (see product label).

Technical specifications

Operating voltage | 230V +/- 10% |

Maximum load | 16A (resistive) |

Isolation | Class II |

Protection | IP30 |

Frequency | 433,42 MHz |

Temperature | Internal sensor 5-30°C |

| Floor sensor 5-40°C |

Temp. limit: | Two sensors 27°C floor |

OFF-switch | No |

Sensor type: | NTC 100kΩ / 25°C |

Measure (l x w x h): | 70 x 70 x 55mm |

Building depth | 32mm |

El. number | 54 683 88 |

| GB |

DigiHeat room thermostat 16A

2NC9 840

580.042b GB 181004