Gas Detector specifications

Sierra Monitor Corporation, a leader in environmental monitoring and gas detection systems, has developed an innovative range of gas detectors tailored for industrial applications. These systems are designed to provide reliable, real-time monitoring of hazardous gases, ensuring the safety of personnel and the environment.One of the standout features of Sierra Monitor's gas detectors is their advanced sensor technology. The devices are equipped with a variety of sensors that can detect a range of gases including methane, hydrogen sulfide, and carbon monoxide. These sensors utilize industry-leading electrochemical and catalytic bead technologies to deliver accurate and responsive measurements, minimizing the risk of false alarms.

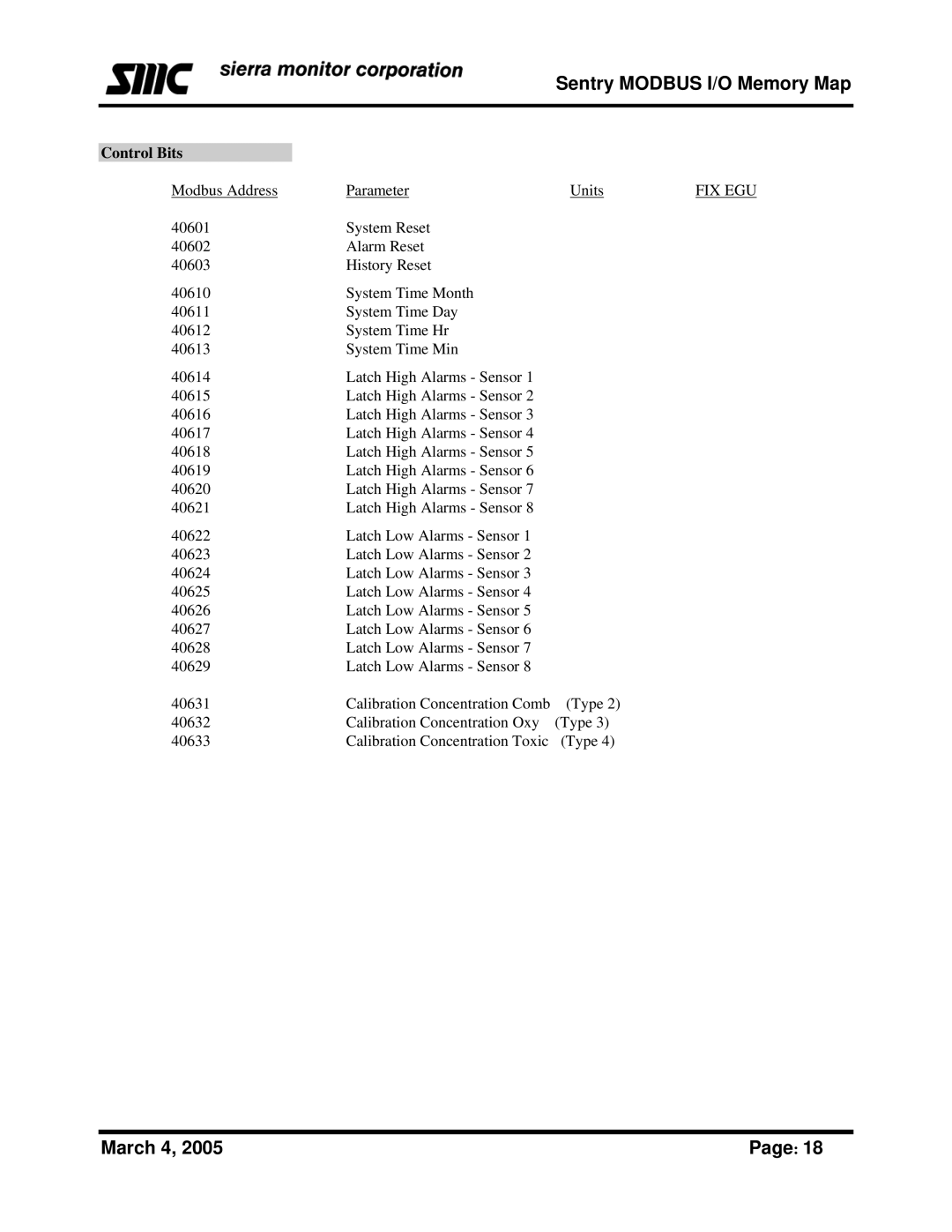

In addition to robust sensor capabilities, Sierra Monitor gas detectors feature intelligent monitoring solutions that facilitate seamless integration with existing facility management systems. The detectors can communicate via various protocols such as Modbus, Ethernet/IP, and BACnet, allowing for real-time data transmission and centralized monitoring. This ensures that facility managers can respond swiftly to any detected gas anomalies, significantly improving workplace safety.

The design of the gas detectors prioritizes durability and flexibility. Many models come with rugged housings that can withstand harsh environmental conditions, making them perfect for use in challenging industrial settings. Additionally, the detectors are often equipped with user-friendly interfaces, allowing for straightforward calibration and maintenance.

Sierra Monitor also places a strong emphasis on user experience. Their gas detectors often include features such as audible alarms, LED indicators, and remote monitoring capabilities. These features help ensure that any hazardous conditions are immediately communicated to personnel, thereby promoting a proactive safety culture.

Moreover, the corporation focuses on innovation in power solutions, offering models with low power consumption and options for battery operation. This allows for deployment in remote locations where power is limited, ensuring essential gas monitoring without interruptions.

Overall, Sierra Monitor Corporation's gas detectors stand out for their combination of cutting-edge technology, user-friendly design, and robust safety features, making them an invaluable asset for industries concerned about gas hazards. By harnessing the latest advancements in sensor technology and connectivity, Sierra Monitor ensures that facilities are equipped not just to detect, but to effectively manage gas-related risks.