Installation | 4 |

DESCRIPTION

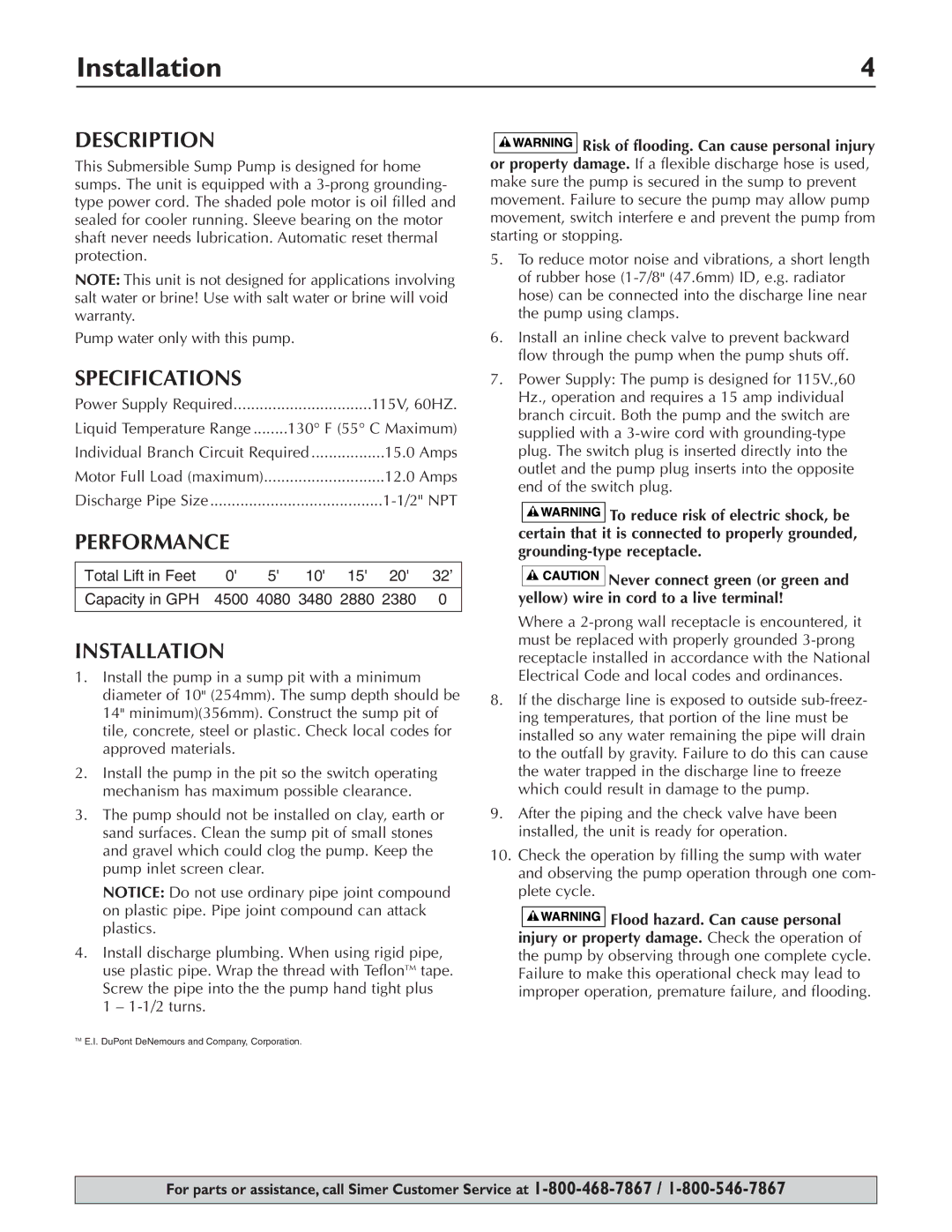

This Submersible Sump Pump is designed for home sumps. The unit is equipped with a

NOTE: This unit is not designed for applications involving salt water or brine! Use with salt water or brine will void warranty.

Pump water only with this pump.

SPECIFICATIONS

Power Supply Required | 115V, 60HZ. | |

Liquid Temperature Range | 130° F (55° C Maximum) | |

Individual Branch Circuit Required | .................15.0 Amps | |

Motor Full Load (maximum) | 12.0 Amps | |

Discharge Pipe Size | ||

PERFORMANCE

Total Lift in Feet | 0' | 5' | 10' 15' 20' | 32’ |

|

|

| ||

Capacity in GPH | 4500 4080 3480 2880 2380 | 0 | ||

|

|

|

|

|

INSTALLATION

1.Install the pump in a sump pit with a minimum diameter of 10" (254mm). The sump depth should be 14" minimum)(356mm). Construct the sump pit of tile, concrete, steel or plastic. Check local codes for approved materials.

2.Install the pump in the pit so the switch operating mechanism has maximum possible clearance.

3.The pump should not be installed on clay, earth or sand surfaces. Clean the sump pit of small stones and gravel which could clog the pump. Keep the pump inlet screen clear.

NOTICE: Do not use ordinary pipe joint compound on plastic pipe. Pipe joint compound can attack plastics.

4.Install discharge plumbing. When using rigid pipe, use plastic pipe. Wrap the thread with TeflonTM tape. Screw the pipe into the the pump hand tight plus 1 –

TM E.I. DuPont DeNemours and Company, Corporation.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Risk of flooding. Can cause personal injury or property damage. If a flexible discharge hose is used, make sure the pump is secured in the sump to prevent movement. Failure to secure the pump may allow pump movement, switch interfere e and prevent the pump from starting or stopping.

Risk of flooding. Can cause personal injury or property damage. If a flexible discharge hose is used, make sure the pump is secured in the sump to prevent movement. Failure to secure the pump may allow pump movement, switch interfere e and prevent the pump from starting or stopping.

5.To reduce motor noise and vibrations, a short length of rubber hose

6.Install an inline check valve to prevent backward flow through the pump when the pump shuts off.

7.Power Supply: The pump is designed for 115V.,60 Hz., operation and requires a 15 amp individual branch circuit. Both the pump and the switch are supplied with a

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() To reduce risk of electric shock, be certain that it is connected to properly grounded,

To reduce risk of electric shock, be certain that it is connected to properly grounded,

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Never connect green (or green and yellow) wire in cord to a live terminal!

Never connect green (or green and yellow) wire in cord to a live terminal!

Where a

8.If the discharge line is exposed to outside

9.After the piping and the check valve have been installed, the unit is ready for operation.

10.Check the operation by filling the sump with water and observing the pump operation through one com- plete cycle.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Flood hazard. Can cause personal injury or property damage. Check the operation of the pump by observing through one complete cycle. Failure to make this operational check may lead to improper operation, premature failure, and flooding.

Flood hazard. Can cause personal injury or property damage. Check the operation of the pump by observing through one complete cycle. Failure to make this operational check may lead to improper operation, premature failure, and flooding.

For parts or assistance, call Simer Customer Service at