INSTRUCTIONS FOR

SIOUX AIR SANDER & POLISHER

NO. 1287—NO. 1238

Form A203B

Date 2004August13/A Page 1 of 1

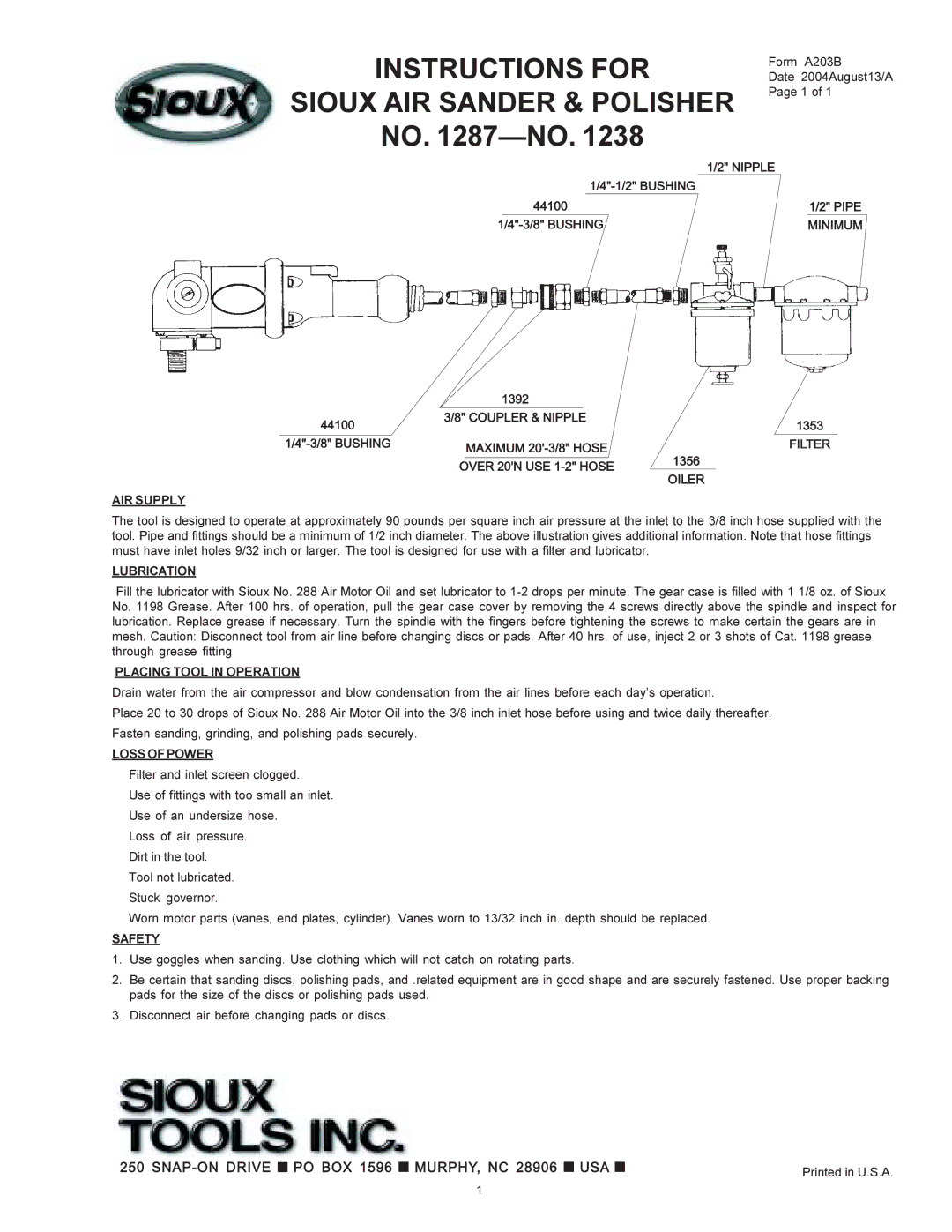

| 1/2" NIPPLE |

| |

44100 | 1/2" PIPE |

MINIMUM |

|

| 1392 |

|

44100 | 3/8" | COUPLER & NIPPLE | 1353 |

|

| ||

| MAXIMUM | FILTER | |

|

|

|

OVER 20'N USE | 1356 |

| |

| OILER |

AIR SUPPLY

The tool is designed to operate at approximately 90 pounds per square inch air pressure at the inlet to the 3/8 inch hose supplied with the tool. Pipe and fittings should be a minimum of 1/2 inch diameter. The above illustration gives additional information. Note that hose fittings must have inlet holes 9/32 inch or larger. The tool is designed for use with a filter and lubricator.

LUBRICATION

Fill the lubricator with Sioux No. 288 Air Motor Oil and set lubricator to

PLACING TOOL IN OPERATION

Drain water from the air compressor and blow condensation from the air lines before each day’s operation.

Place 20 to 30 drops of Sioux No. 288 Air Motor Oil into the 3/8 inch inlet hose before using and twice daily thereafter. Fasten sanding, grinding, and polishing pads securely.

LOSSOFPOWER

Filter and inlet screen clogged.

Use of fittings with too small an inlet.

Use of an undersize hose.

Loss of air pressure.

Dirt in the tool.

Tool not lubricated.

Stuck governor.

Worn motor parts (vanes, end plates, cylinder). Vanes worn to 13/32 inch in. depth should be replaced.

SAFETY

1.Use goggles when sanding. Use clothing which will not catch on rotating parts.

2.Be certain that sanding discs, polishing pads, and .related equipment are in good shape and are securely fastened. Use proper backing pads for the size of the discs or polishing pads used.

3.Disconnect air before changing pads or discs.

Printed in U.S.A.

1