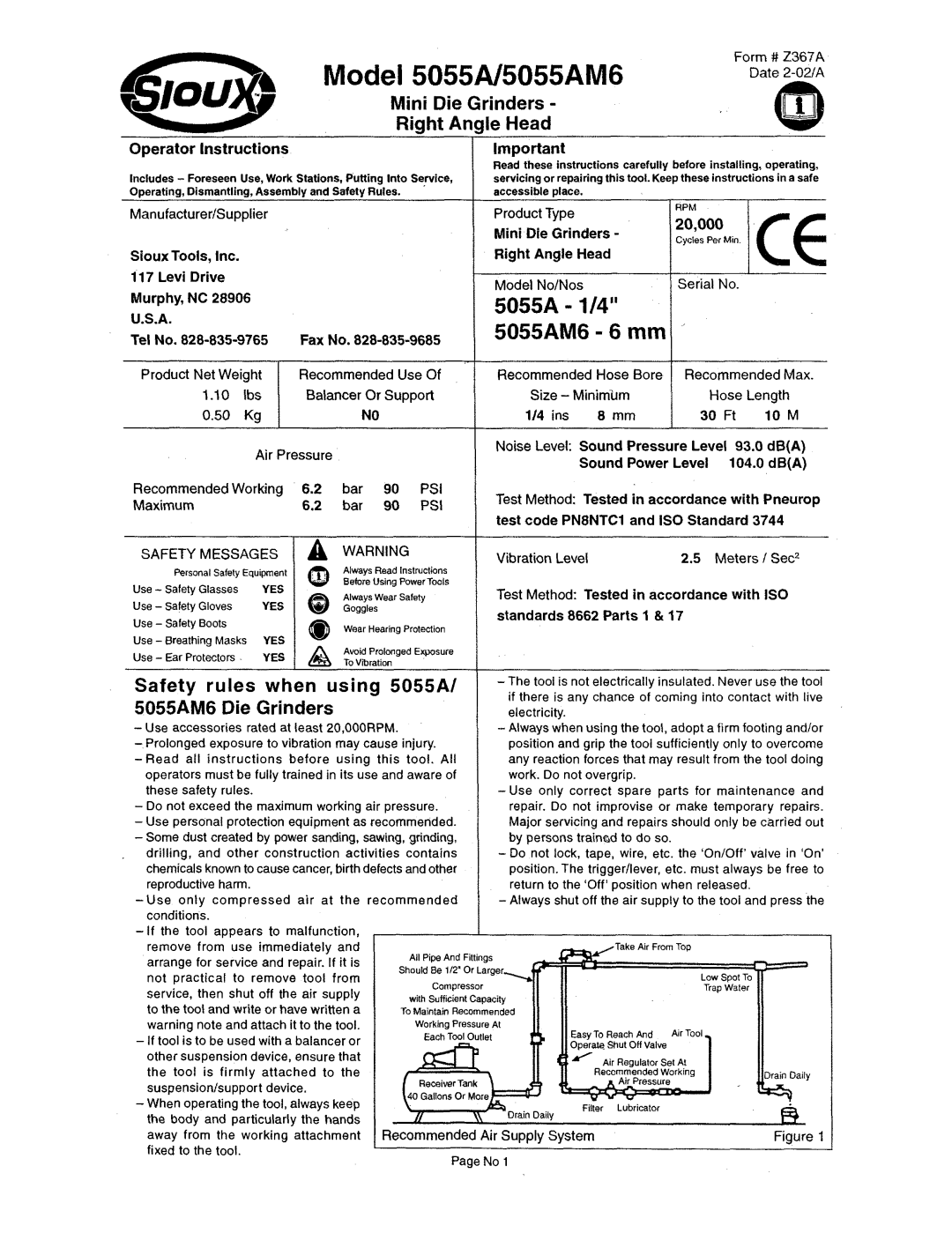

5055A, 5055AM6 specifications

Sioux Tools has long been synonymous with precision engineering and high-quality pneumatic tools. Among their renowned offerings, the Sioux Tools 5055AM6 and 5055A pneumatic screwdrivers stand out for their exceptional performance and reliability. These tools are designed to meet the demanding needs of industrial environments, delivering efficiency and precision in fastening applications.One of the main features of both models is their robust construction, ensuring durability even in the most challenging work conditions. The Sioux Tools 5055AM6 and 5055A both feature a lightweight design, which minimizes operator fatigue during prolonged use. This ergonomic design, combined with a balanced structure, allows for easy maneuverability and enhances overall user comfort.

Both models offer an adjustable torque setting, enabling users to accurately control the amount of force applied during fastening. This feature is particularly valuable in assembly lines where consistency is crucial. The torque control mechanism ensures that fasteners are neither over-tightened nor stripped, maintaining the integrity of the connections.

The Sioux Tools 5055AM6 stands out with its innovative anti-slip grip, which provides added control during operation. Furthermore, it incorporates a powerful motor that ensures high-speed performance, making it suitable for various applications, from automotive to aerospace industries. The 5055A, while similar in design, offers slightly different specifications tailored for specific fastening requirements.

Both models utilize advanced technologies to enhance their performance. They feature an efficient air motor that reduces cycle times while providing consistent output power. Additionally, the incorporation of a noise-reducing design minimizes sound levels, creating a more pleasant working environment for operators.

In terms of maintenance, Sioux Tools engineers have designed these screwdrivers for easy disassembly, allowing for quick cleaning and servicing. This feature extends the lifespan of the tools and ensures minimal downtime for businesses relying on them in production environments.

Overall, the Sioux Tools 5055AM6 and 5055A pneumatic screwdrivers epitomize quality and innovation. Their combination of ergonomic design, versatile torque control, and advanced technology makes them essential tools for professionals seeking efficiency and reliability in their fastening applications. Whether in assembly lines or repair shops, these screwdrivers provide outstanding performance that users can depend on.