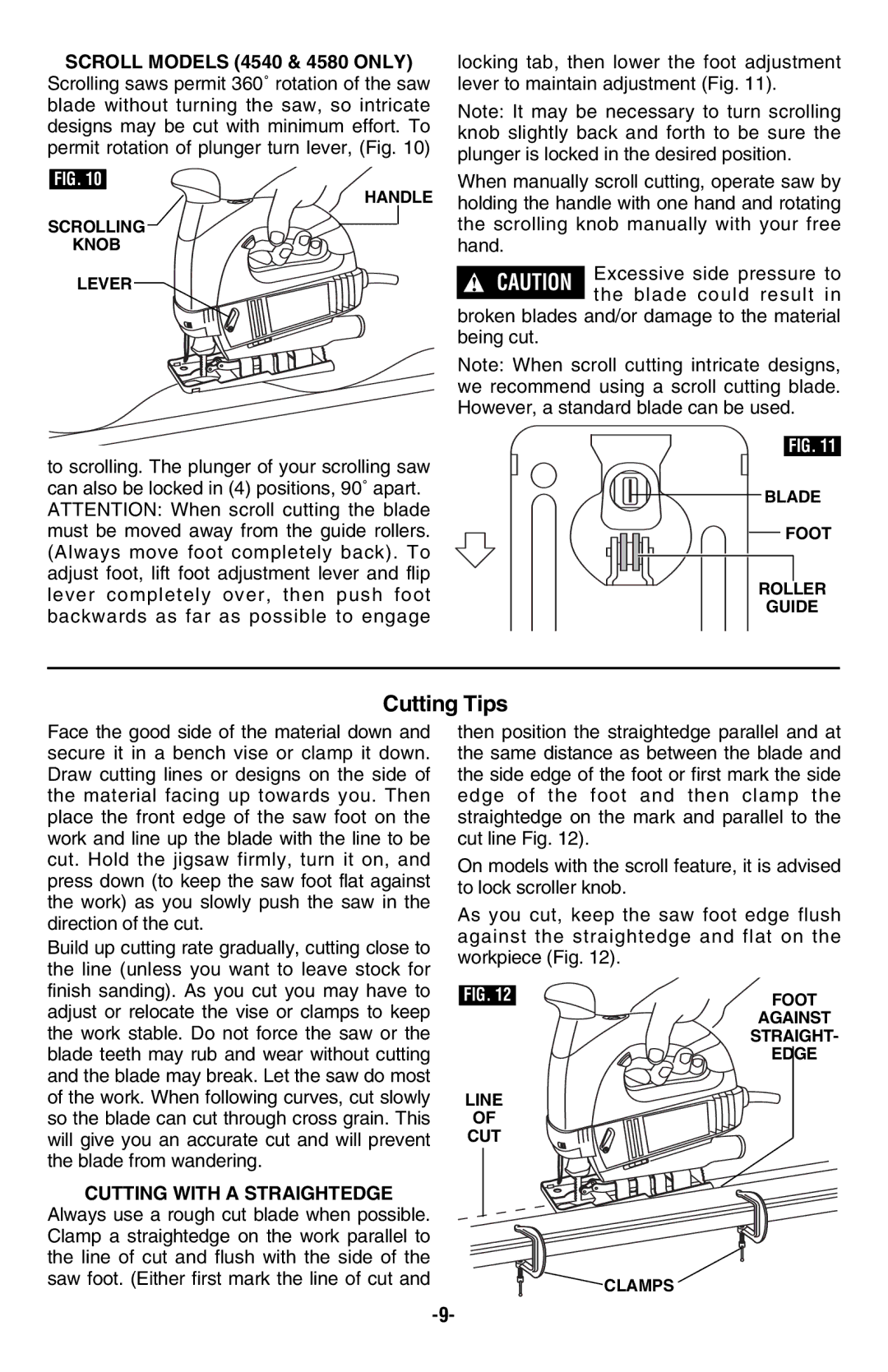

SCROLL MODELS (4540 & 4580 ONLY) Scrolling saws permit 360˚ rotation of the saw blade without turning the saw, so intricate designs may be cut with minimum effort. To permit rotation of plunger turn lever, (Fig. 10)

FIG. 10

HANDLE

SCROLLING

KNOB

LEVER![]()

to scrolling. The plunger of your scrolling saw can also be locked in (4) positions, 90˚ apart. ATTENTION: When scroll cutting the blade must be moved away from the guide rollers. (Always move foot completely back). To adjust foot, lift foot adjustment lever and flip lever completely over, then push foot backwards as far as possible to engage

locking tab, then lower the foot adjustment lever to maintain adjustment (Fig. 11).

Note: It may be necessary to turn scrolling knob slightly back and forth to be sure the plunger is locked in the desired position.

When manually scroll cutting, operate saw by holding the handle with one hand and rotating the scrolling knob manually with your free hand.

!CAUTION Excessive side pressure to the blade could result in

broken blades and/or damage to the material being cut.

Note: When scroll cutting intricate designs, we recommend using a scroll cutting blade. However, a standard blade can be used.

FIG. 11

BLADE

FOOT

ROLLER

GUIDE

Cutting Tips

Face the good side of the material down and secure it in a bench vise or clamp it down. Draw cutting lines or designs on the side of the material facing up towards you. Then place the front edge of the saw foot on the work and line up the blade with the line to be cut. Hold the jigsaw firmly, turn it on, and press down (to keep the saw foot flat against the work) as you slowly push the saw in the direction of the cut.

Build up cutting rate gradually, cutting close to the line (unless you want to leave stock for finish sanding). As you cut you may have to adjust or relocate the vise or clamps to keep the work stable. Do not force the saw or the blade teeth may rub and wear without cutting and the blade may break. Let the saw do most of the work. When following curves, cut slowly so the blade can cut through cross grain. This will give you an accurate cut and will prevent the blade from wandering.

CUTTING WITH A STRAIGHTEDGE

Always use a rough cut blade when possible. Clamp a straightedge on the work parallel to the line of cut and flush with the side of the saw foot. (Either first mark the line of cut and

then position the straightedge parallel and at the same distance as between the blade and the side edge of the foot or first mark the side edge of the foot and then clamp the straightedge on the mark and parallel to the cut line Fig. 12).

On models with the scroll feature, it is advised to lock scroller knob.

As you cut, keep the saw foot edge flush against the straightedge and flat on the workpiece (Fig. 12).

FIG. 12 | FOOT |

| AGAINST |

| STRAIGHT- |

| EDGE |

LINE

OF

CUT

![]() CLAMPS

CLAMPS