SM 1619X02966

LINE GUIDE

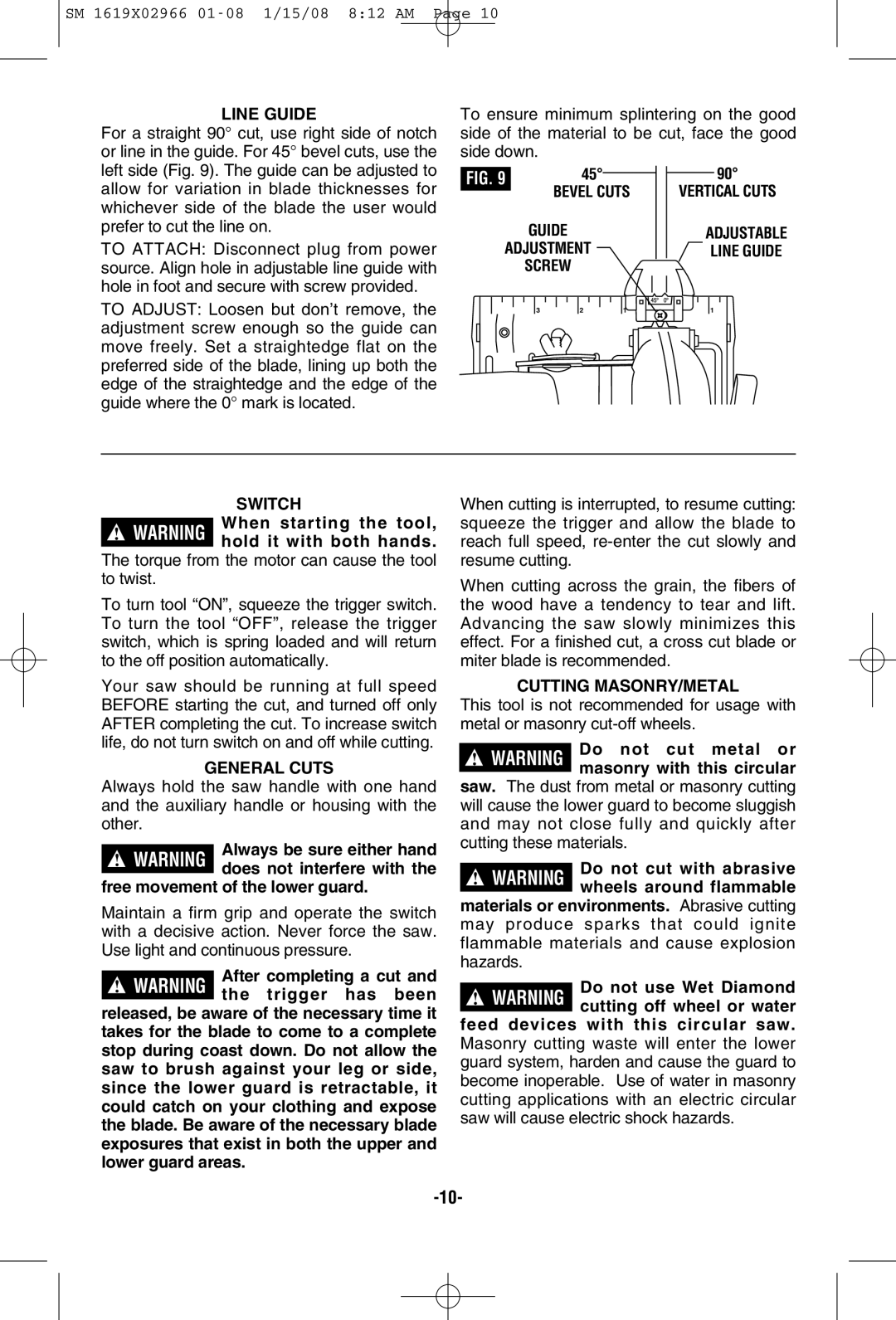

For a straight 90° cut, use right side of notch or line in the guide. For 45° bevel cuts, use the left side (Fig. 9). The guide can be adjusted to allow for variation in blade thicknesses for whichever side of the blade the user would prefer to cut the line on.

TO ATTACH: Disconnect plug from power source. Align hole in adjustable line guide with hole in foot and secure with screw provided.

TO ADJUST: Loosen but don’t remove, the adjustment screw enough so the guide can move freely. Set a straightedge flat on the preferred side of the blade, lining up both the edge of the straightedge and the edge of the guide where the 0° mark is located.

To ensure minimum splintering on the good side of the material to be cut, face the good side down.

FIG. 9 | 45° |

|

|

| 90° |

|

| ||||

| BEVEL CUTS |

| VERTICAL CUTS | ||

| |||||

GUIDEADJUSTABLE

ADJUSTMENTLINE GUIDE SCREW

3 | 2 | 1 | 45 | 0 | 1 |

|

SWITCH

When starting the tool, ! WARNING hold it with both hands.

The torque from the motor can cause the tool to twist.

To turn tool “ON”, squeeze the trigger switch. To turn the tool “OFF”, release the trigger switch, which is spring loaded and will return to the off position automatically.

Your saw should be running at full speed BEFORE starting the cut, and turned off only AFTER completing the cut. To increase switch life, do not turn switch on and off while cutting.

GENERAL CUTS

Always hold the saw handle with one hand and the auxiliary handle or housing with the other.

Always be sure either hand ! WARNING does not interfere with the

free movement of the lower guard.

Maintain a firm grip and operate the switch with a decisive action. Never force the saw. Use light and continuous pressure.

After completing a cut and ! WARNING the trigger has been

released, be aware of the necessary time it takes for the blade to come to a complete stop during coast down. Do not allow the saw to brush against your leg or side, since the lower guard is retractable, it could catch on your clothing and expose the blade. Be aware of the necessary blade exposures that exist in both the upper and lower guard areas.

When cutting is interrupted, to resume cutting: squeeze the trigger and allow the blade to reach full speed,

When cutting across the grain, the fibers of the wood have a tendency to tear and lift. Advancing the saw slowly minimizes this effect. For a finished cut, a cross cut blade or miter blade is recommended.

CUTTING MASONRY/METAL

This tool is not recommended for usage with metal or masonry

!WARNING Do not cut metal or masonry with this circular

saw. The dust from metal or masonry cutting will cause the lower guard to become sluggish and may not close fully and quickly after cutting these materials.

Do not cut with abrasive ! WARNING wheels around flammable

materials or environments. Abrasive cutting may produce sparks that could ignite flammable materials and cause explosion hazards.

Do not use Wet Diamond ! WARNING cutting off wheel or water

feed devices with this circular saw. Masonry cutting waste will enter the lower guard system, harden and cause the guard to become inoperable. Use of water in masonry cutting applications with an electric circular saw will cause electric shock hazards.