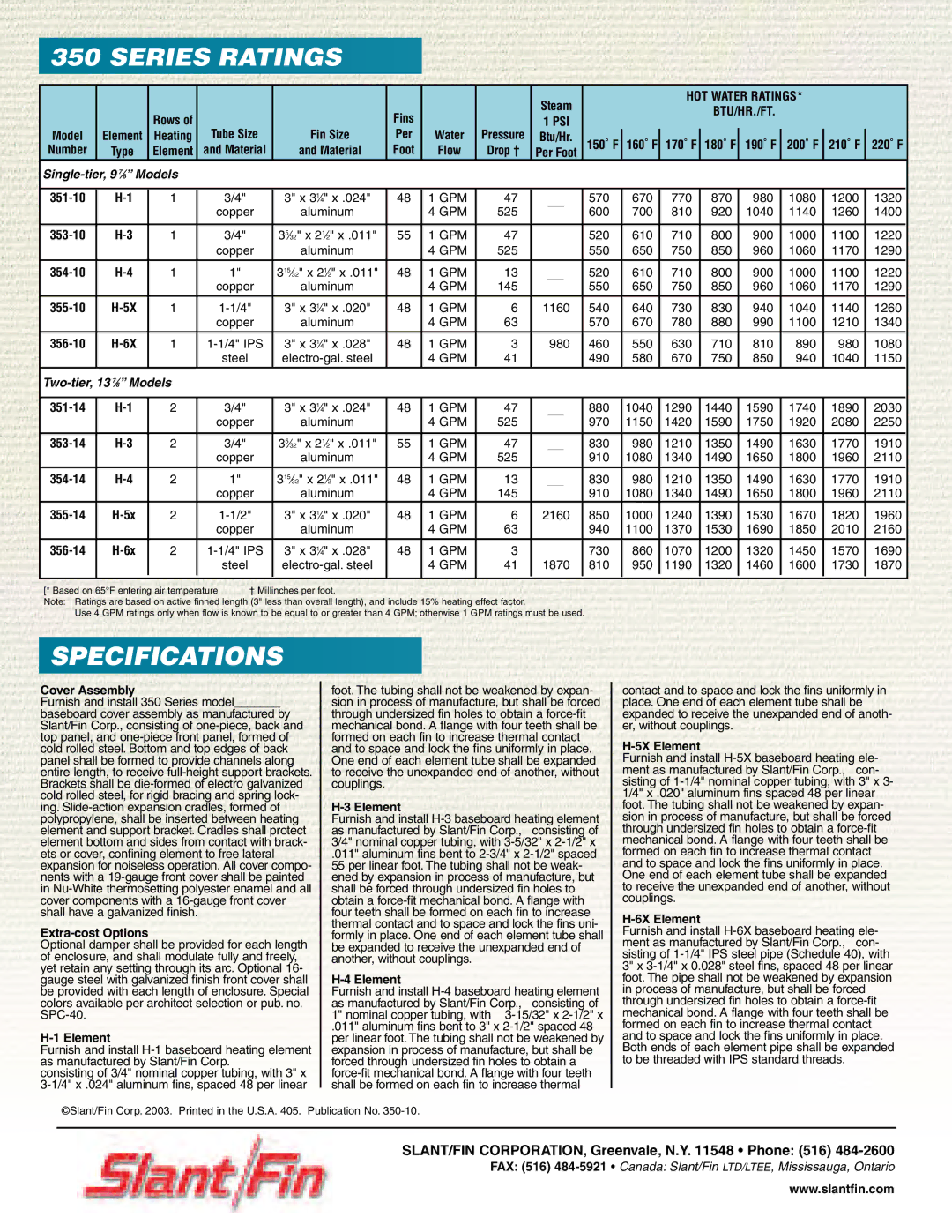

350 Series specifications

The Slant/Fin 350 Series represents a significant advancement in hot water heating technology, designed to provide efficient, reliable, and consistent heating for various residential and commercial applications. Known for its robust construction and user-friendly features, this series has garnered a strong reputation in the industry.One of the main features of the Slant/Fin 350 Series is its high-efficiency design. Equipped with advanced combustion technology, these boilers maximize heat output while minimizing fuel consumption. This not only helps in reducing energy costs but also contributes to a lower carbon footprint, making it an eco-friendly choice for modern heating needs.

The Slant/Fin 350 Series utilizes a cast iron heat exchanger, which is renowned for its durability and superior heat retention capabilities. This material ensures that the boiler can withstand high temperatures without compromising its structural integrity, resulting in a long-lasting product that can operate efficiently for many years. Additionally, the series includes a built-in venting system that enhances performance and reliability by ensuring optimal airflow.

Another notable characteristic of the Slant/Fin 350 Series is its user-friendly control interface. The integrated digital display allows homeowners and technicians to monitor and adjust the system settings easily, providing real-time feedback on temperature and performance. This feature is especially beneficial for those who prefer a more hands-on approach to managing their heating system.

The 350 Series also offers flexible installation options, making it suitable for various layouts and settings. Whether placed in a basement, utility room, or a designated mechanical space, its compact design and versatile venting options ensure that installation is straightforward and convenient.

Moreover, the Slant/Fin 350 Series is designed with safety in mind. The unit comes equipped with multiple safety features, such as pressure relief valves and automatic shut-off mechanisms, which work together to prevent potential hazards and ensure peace of mind for users.

In conclusion, the Slant/Fin 350 Series stands out due to its combination of high efficiency, durability, user-friendly controls, flexible installation parameters, and enhanced safety features. With these advancements, it provides a reliable and effective heating solution that meets the demands of today's energy-conscious consumers. Homeowners and business operators looking for a dependable heating system will find the Slant/Fin 350 Series to be a strong contender for their heating needs.