Installation and Maintenance Manual

Solid State

D-H7BA, D-H7B, D-H7BW, D-H7NW, D-H7PW

For future reference, please keep this manual in a safe place

This manual should be read in conjunction with the current product catalogue

Problem |

3 wire type NPN output |

|

| 3 wire type PNP output |

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| DC(+) |

|

| |

|

|

|

|

| DC(+) |

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Brown (Red) |

|

| ||

|

|

|

| Brown (Red) |

|

|

|

| |||||||||

|

|

|

|

| OUT |

|

|

|

|

|

|

|

| OUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

| Switch |

|

|

|

|

| Load | |

| Switch |

|

|

|

|

| Load | ||||||||||

|

|

|

|

|

|

|

| Power |

|

|

| Black (White) |

| Power | |||

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

| |||||||||

|

|

| Black (White) |

|

| ||||||||||||

|

|

|

| source |

|

|

|

|

|

|

|

| source | ||||

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Safety Instructions

These safety instructions are intended to prevent a hazardous situa- tion and/or equipment damage. These instructions indicate the level of potential hazard by label of “Caution”, “Warning” or “Danger”. To ensure safety, be sure to observe ISO4414 (Note1), JIS B 8370 (Note2) and other safety practices.

Note 1: ISO 4414: Pneumatic fluid power – Recommendations for the application of equipment to transmission and control systems.

Note 2: JIS B 8370: Pneumatic system axiom.

CAUTION : Operator error could result in injury or equipment damage.

WARNING : Operator error could result in serious

2. Only trained personnel should operate pneumatically |

operated machinery and equipment. |

Compressed air can be dangerous if an operator is unfamiliar |

with it. Assembly, handling or repair of pneumatic systems should |

be performed by trained and experienced operators. |

3. Do not service machinery/equipment or attempt to |

remove component until safety is confirmed. |

1) Inspection and maintenance of machinery/equipment should |

only be performed after confirmation of safe |

control positions. |

2) When equipment is to be removed, confirm the safety process |

as mentioned above. Switch off air and electrical supplies and |

exhaust all residual compressed air in the system. |

3) Before machinery/equipment is |

measures to prevent sudden movement of cylinders etc. |

| Condition |

|

|

|

|

| Stay ON |

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

| (sometimes OFF) |

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Indicator |

|

| Stay ON | |||

| Stay OFF |

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| lamp lights |

|

| |||||||

(sometimes ON) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| Stay | OFF |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Normal |

|

|

|

| ||

| Indicator |

| Stay OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| lamp lights |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Normal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| Source voltage |

|

|

|

|

|

| 2 wires/ |

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

| or load voltage |

|

|

|

|

|

|

| 3 wires |

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Blue (Black) |

|

|

|

|

| Blue (Black) |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 wire type (Sink output) |

|

| 2 wire type (Source output) |

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| OUT(+) |

|

|

|

|

| OUT(+) |

|

| ||

|

|

|

|

|

|

| Load |

|

|

|

|

| Power | ||

|

|

|

|

|

|

|

|

|

|

|

| Brown (Red) | |||

|

|

|

| Brown (Red) |

|

|

|

|

| source | |||||

|

|

|

|

|

|

| Switch | ||||||||

| Switch |

|

|

|

|

| Power |

|

|

|

| ||||

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

| source |

|

|

| Load | ||||||

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

| Blue (Black) |

|

|

|

|

|

| Blue (Black) |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig 4

injury or loss of life.

DANGER : In extreme conditions, there is a possible result of serious injury or loss of life.

WARNING

1.The compatibility of pneumatic equipment is the respon- sibility of the person who designs the pneumatic system or decides its specifications.

Since the products specified here are used in various operating conditions, their compatibility for the specific pneumatic system must be based on specifications or after analysis and/or tests to meet your specific requirements.

1.Product specification

| (Bleed air into the system gradually to create |

| i.e. incorporate a |

4. Contact SMC if the product is to be used in any of the | |

following conditions: | |

1) | Conditions and environments beyond the given specifica- |

| tions, or if product is used outdoors. |

2) | Installations in conjunction with atomic energy, railway, air |

| navigation, vehicles, medical equipment, food and beverage, |

| recreation equipment, emergency stop circuits, press |

| applications, or safety equipment. |

3) | An application which has the possibility of having negative |

| effects on people, property, or animals, requiring special |

| safety analysis. |

CAUTION

Ensure that the air supply system is filtered to 5 micron.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Normal |

|

|

|

|

| Abnormal |

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3 wires |

| 2 wires |

|

|

|

| ||||||||

| 2 wires/ |

|

|

|

| 2 wires |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

| 3 wires |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| 3 | wires |

|

|

|

|

|

| Load | spec. |

|

|

|

|

| Replace the |

|

|

|

|

|

|

|

|

|

|

| Load spec. |

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

| check 1 |

|

|

|

|

| switch |

|

|

|

|

|

|

|

|

|

|

|

| check 2 |

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

| Normal |

| Abnormal |

| Normal |

| Abnormal |

|

|

|

|

|

|

| Normal |

| Abnormal |

| ||||||||||||

| Wiring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| (output) check |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Normal |

| Abnormal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| B |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| A |

|

| B |

|

|

|

| A |

| C | D |

|

|

| E | B | A |

| A |

| F | D | ||||||||||||||||

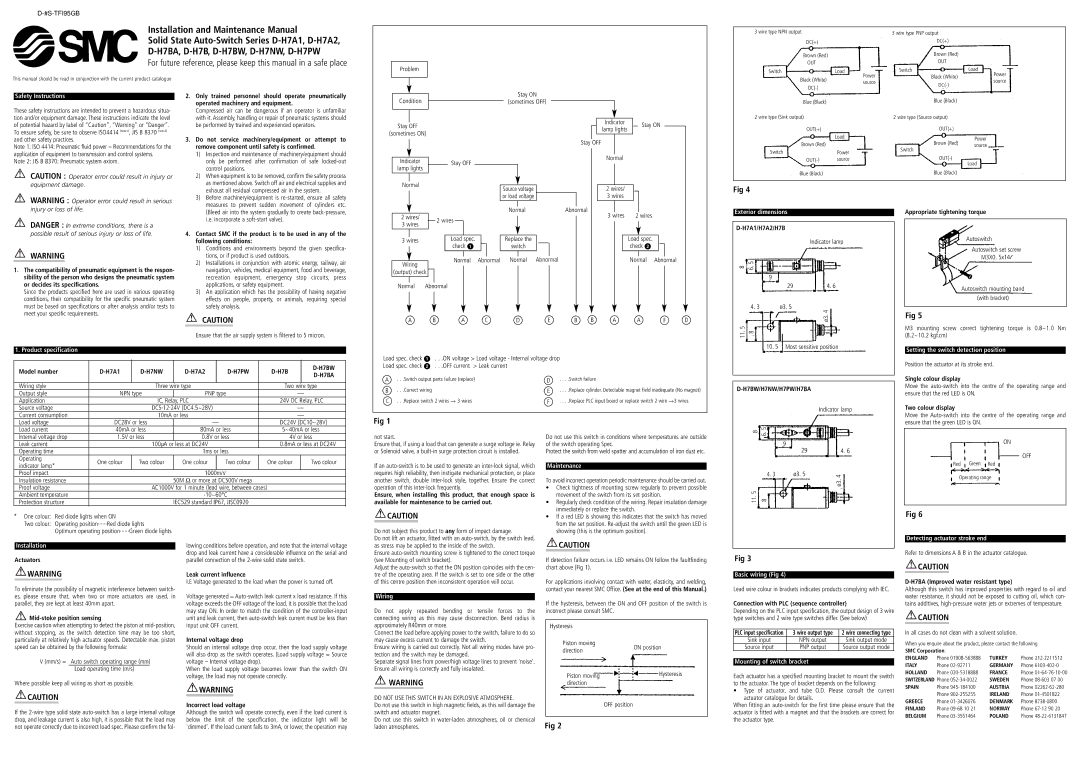

Load spec. check 1 . . .ON voltage > Load voltage - Internal voltage drop |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

Exterior dimensions

Indicator lamp

8 | 5 |

|

|

. |

|

| |

6 |

|

| |

|

|

| |

|

| 9 |

|

|

| 29 | 4. 6 |

| 4. 3 | ø3. 5 | 4 |

|

|

| |

|

|

| . |

|

|

| ø3 |

5 |

|

|

|

. | 8 |

|

|

11 |

|

| |

|

|

| |

|

| 10. 5 Most sensitive position | |

Appropriate tightening torque

Autoswitch

Autoswitch set screw

M3X0. 5x14l

Autoswitch mounting band

(with bracket)

Fig 5

M3 mounting screw correct tightening torque is 0.8~1.0 Nm (8.2~10.2 kgf.cm)S

Setting the switch detection position

Model number |

|

|

| ||||

| |||||||

|

|

|

|

|

| ||

|

|

|

|

|

| ||

Wiring style |

| Three wire type |

| Two wire type | |||

Output style | NPN type | PNP type |

|

| |||

Application |

| IC, Relay, PLC |

| 24V DC Relay, PLC | |||

Source voltage |

| DC5·12·24V (DC4.5~28V) |

|

| |||

Load spec. check 2 . . .OFF current > Leak current |

|

| |

A | . . .Switch output parts failure (replace) | D | . . . .Switch failure |

B | . . .Correct wiring | E | . . . .Replace cylinder. Detectable magnet field inadequate (No magnet) |

C | . . .Replace switch 2 wires R 3 wires | F | . . . .Replace PLC input board or replace switch 2 wire R3 wires |

|

Indicator lamp |

Position the actuator at its stroke end.

Single colour display

Move the

Two colour display

Current consumption |

| 10mA or less |

|

|

|

| |||

Load voltage | DC28V or less |

| DC24V (DC10~28V) | ||||||

Load current | 40mA or less | 80mA or less | 5~40mA or less | ||||||

Internal voltage drop | 1.5V or less | 0.8V or less | 4V or less | ||||||

Leak current |

| 100µA or | less at DC24V |

|

|

| 0.8mA or less at DC24V | ||

Operating time |

|

| 1ms or less |

|

|

| |||

Operating | One colour | Two colour | One colour |

| Two colour |

| One colour |

| Two colour |

indicator lamp* |

|

|

| ||||||

|

|

|

|

|

|

|

|

| |

Proof impact |

|

| 1000m/s2 |

|

|

| |||

Insulation resistance |

|

| 50M Ω or more at DC500V mega |

|

|

| |||

Proof voltage |

| AC1000V for 1 minute (lead wire, between cases) |

|

|

| ||||

Ambient temperature |

|

|

|

|

| ||||

Protection structure |

|

| IEC529 standard IP67, JISC0920 |

|

|

| |||

*One colour: Red diode lights when ON

Two colour: Operating position······Red diode lights Optimum operating position······Green diode lights

Installation | lowing conditions before operation, and note that the internal voltage |

Actuators | drop and leak current have a considerable influence on the serial and |

parallel connection of the |

Fig 1

not start.

Ensure that, if using a load that can generate a surge voltage ie. Relay or Solenoid valve, a

If an

Ensure, when installing this product, that enough space is available for maintenance to be carried out.

![]() CAUTION

CAUTION

Do not subject this product to any form of impact damage.

Do not lift an actuator, fitted with an

Ensure

Do not use this switch in conditions where temperatures are outside of the switch operating Spec.

Protect the switch from weld spatter and accumulation of iron dust etc.

Maintenance

To avoid incorrect operation periodic maintenance should be carried out.

•Check tightness of mounting screw regularly to prevent possible movement of the switch from its set position.

•Regularly check condition of the wiring. Repair insulation damage immediately or replace the switch.

•If a red LED is showing this indicates that the switch has moved from the set position.

![]() CAUTION

CAUTION

If detection failure occurs i.e. LED remains ON follow the faultfinding

| 5 |

|

|

8 . |

|

| |

| 6 |

|

|

|

| 9 |

|

|

| 29 | 4. 6 |

| 4. 3 | ø3. 5 | 4 |

|

|

| . |

|

|

| ø3 |

5 |

|

|

|

. |

|

|

|

11 | 8 |

|

|

Fig 3

Move the

ON

OFF

Red Green Red

Operating range

Fig 6

Detecting actuator stroke end

Refer to dimensions A & B in the actuator catalogue.

![]() WARNING

WARNING

To eliminate the possibility of magnetic interference between switch- es, please ensure that, when two or more actuators are used, in parallel, they are kept at least 40mm apart.

Mid-stoke position sensing

Exercise caution when attempting to detect the piston at

V (mm/s) = Auto switch operating range (mm)

Load operating time (m/s)

Where possible keep all wiring as short as possible.

![]() CAUTION

CAUTION

If the

Leak current influence

I.E Voltage generated to the load when the power is turned off.

Voltage generated =

Internal voltage drop

Should an internal voltage drop occur, then the load supply voltage will also drop as the switch operates. (Load supply voltage = Source voltage – Internal voltage drop).

When the load supply voltage becomes lower than the switch ON voltage, the load may not operate correctly.

![]() WARNING

WARNING

Incorrect load voltage

Although the switch will operate correctly, even if the load current is below the limit of the specification, the indicator light will be 'dimmed'. If the load current falls to 3mA, or lower, the operation may

Adjust the

Wiring

Do not apply repeated bending or tensile forces to the connecting wiring as this may cause disconnection. Bend radius is approximately R40mm or more.

Connect the load before applying power to the switch, failure to do so may cause excess current to damage the switch.

Ensure wiring is carried out correctly. Not all wiring modes have pro- tection and the switch may be damaged.

Separate signal lines from power/high voltage lines to prevent 'noise'. Ensure all wiring is correctly and fully insulated.

![]() WARNING

WARNING

DO NOT USE THIS SWITCH IN AN EXPLOSIVE ATMOSPHERE.

Do not use this switch in high magnetic fields, as this will damage the switch and actuator magnet.

Do not use this switch in

chart above (Fig 1).

For applications involving contact with water, elasticity, and welding, contact your nearest SMC Office. (See at the end of this Manual.)

If the hysteresis, between the ON and OFF position of the switch is incorrect please consult SMC.

Hysteresis

Piston moving |

|

|

|

|

|

|

|

| ON position |

| |||

direction |

|

|

| |||

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

Piston moving |

|

|

|

| Hysteresis | |

direction |

|

|

|

|

|

|

|

|

|

| |||

|

| OFF position | ||||

|

|

|

|

|

|

|

Fig 2

Basic wiring (Fig 4)

Lead wire colour in brackets indicates products complying with IEC.

Connection with PLC (sequence controller)

Depending on the PLC input specification, the output design of 3 wire type switches and 2 wire type switches differ. (See below)

PLC input specification | 3 wire output type | 2 wire connecting type |

Sink input | NPN output | Sink output mode |

Source input | PNP output | Source output mode |

Mounting of switch bracket

Each actuator has a specified mounting bracket to mount the switch to the actuator. The type of bracket depends on the following:

•Type of actuator, and tube O.D. Please consult the current actuator catalogue for details.

When fitting an

CAUTION

D-H7BA (Improved water resistant type)

Although this switch has improved properties with regard to oil and water resistance, it should not be exposed to cutting oil, which con- tains additives,

![]() CAUTION

CAUTION

In all cases do not clean with a solvent solution.

When you enquire about the product, please contact the following

SMC Corporation: |

|

| |

ENGLAND | Phone | TURKEY | Phone |

ITALY | Phone | GERMANY | Phone |

HOLLAND | Phone | FRANCE | Phone |

SWITZERLAND Phone | SWEDEN | Phone | |

SPAIN | Phone | AUSTRIA | Phone |

| Phone | IRELAND | Phone |

GREECE | Phone | DENMARK | Phone |

FINLAND | Phone | NORWAY | Phone |

BELGIUM | Phone | POLAND | Phone |