SECTION 4 - ADJUSTMENTS & REPAIR

FLOOR

SHOWN WITH COVER REMOVED

| HANGER |

HAIR PIN | CHAIN PIVOT |

SUPPORT

BRACKET

HANGER

CHAIN

FIGURE 4.4

WARNING

DO NOT attempt any adjustments, maintenance, service or repairs with the engine running. STOP engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. Avoid serious burns, allow all parts to cool before working on machine. Fuel Filler Cap and vent must be closed securely to prevent fuel spillage.

4.2.4.CUTTING HEIGHT ADJUSTMENT The deck cutting height range may be adjusted.

1. Place the Rear Engine Rider on a smooth, level surface.

2. Move deck lift lever to the lowest cutting position.

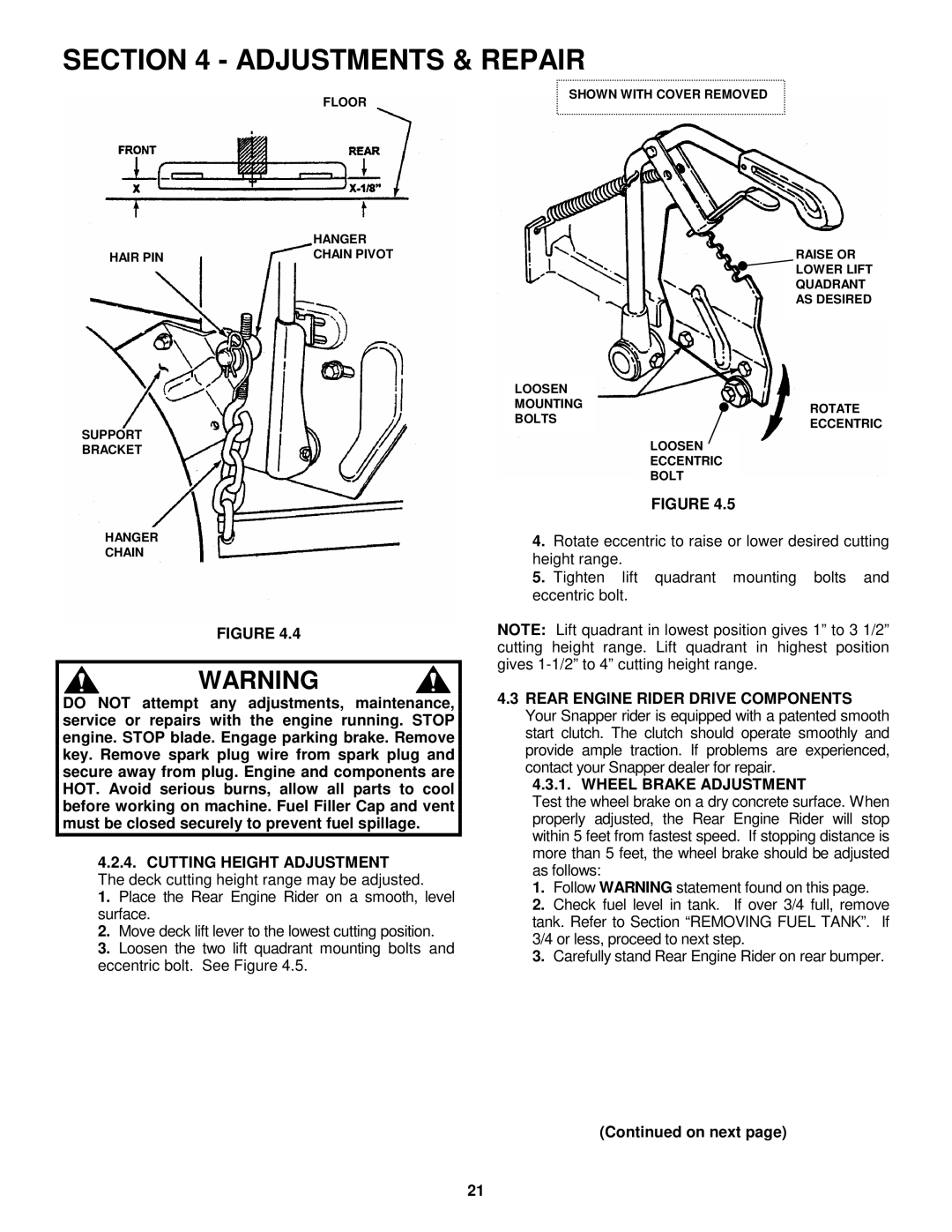

3. Loosen the two lift quadrant mounting bolts and eccentric bolt. See Figure 4.5.

RAISE OR

![]() LOWER LIFT

LOWER LIFT

QUADRANT

AS DESIRED

LOOSEN |

|

|

MOUNTING |

| ROTATE |

BOLTS |

| |

| ECCENTRIC | |

|

| |

|

|

|

|

|

|

LOOSEN

ECCENTRIC

BOLT

FIGURE 4.5

4.Rotate eccentric to raise or lower desired cutting height range.

5.Tighten lift quadrant mounting bolts and eccentric bolt.

NOTE: Lift quadrant in lowest position gives 1” to 3 1/2” cutting height range. Lift quadrant in highest position gives

4.3REAR ENGINE RIDER DRIVE COMPONENTS Your Snapper rider is equipped with a patented smooth start clutch. The clutch should operate smoothly and provide ample traction. If problems are experienced, contact your Snapper dealer for repair.

4.3.1. WHEEL BRAKE ADJUSTMENT

Test the wheel brake on a dry concrete surface. When properly adjusted, the Rear Engine Rider will stop within 5 feet from fastest speed. If stopping distance is more than 5 feet, the wheel brake should be adjusted as follows:

1.Follow WARNING statement found on this page.

2.Check fuel level in tank. If over 3/4 full, remove tank. Refer to Section “REMOVING FUEL TANK”. If 3/4 or less, proceed to next step.

3.Carefully stand Rear Engine Rider on rear bumper.

(Continued on next page)

21