Section 4 - ADJUSTMENT & REPAIR

4.3.4.TRACTION DRIVE BELT ADJUSTMENT Should a gradual loss of traction be noticed, it may be necessary to adjust the traction drive belt tension. Adjust as follows:

1.Move tractor to a firm, level surface.

2.Turn engine "OFF". Remove key.

3.Remove mowing deck.

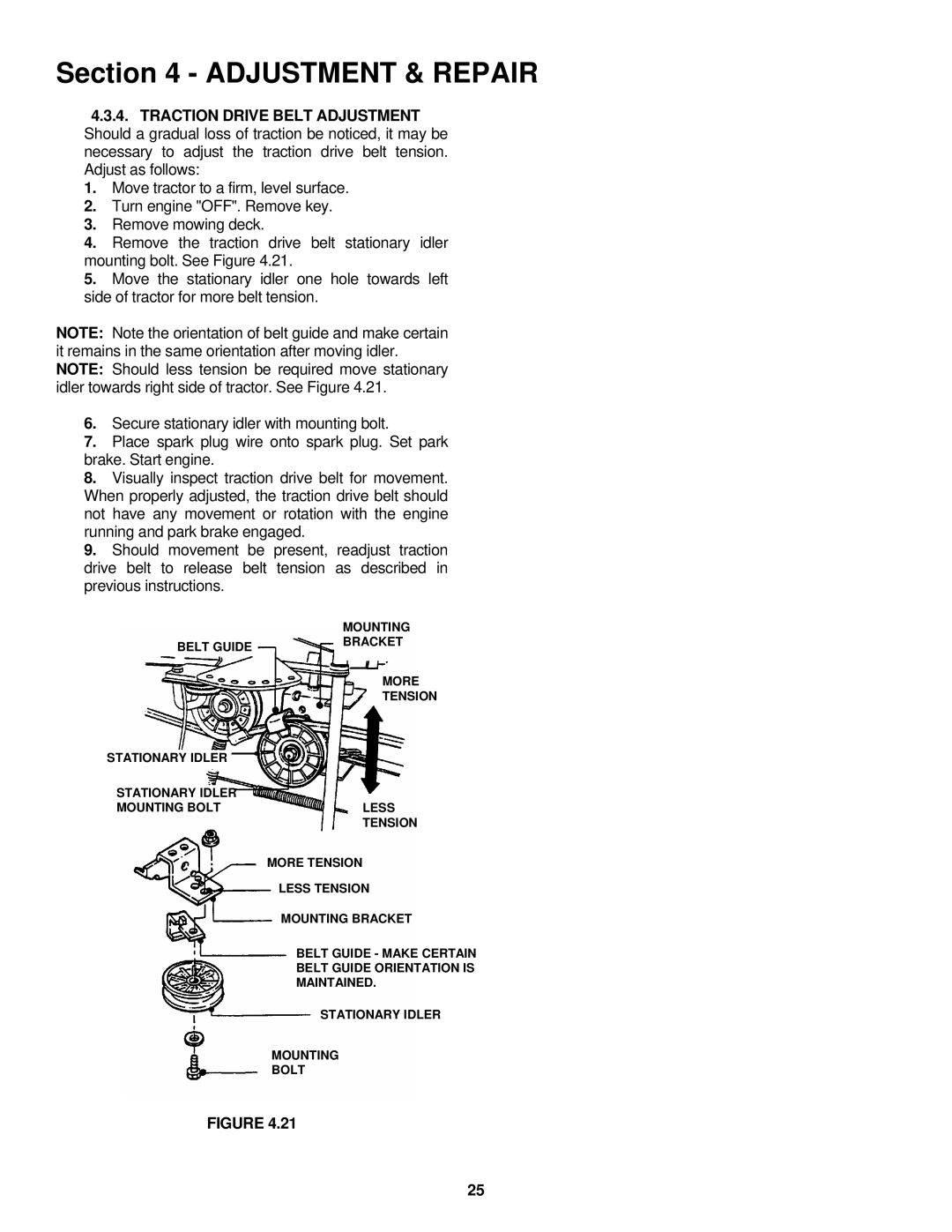

4.Remove the traction drive belt stationary idler mounting bolt. See Figure 4.21.

5.Move the stationary idler one hole towards left side of tractor for more belt tension.

NOTE: Note the orientation of belt guide and make certain it remains in the same orientation after moving idler. NOTE: Should less tension be required move stationary idler towards right side of tractor. See Figure 4.21.

6.Secure stationary idler with mounting bolt.

7.Place spark plug wire onto spark plug. Set park brake. Start engine.

8.Visually inspect traction drive belt for movement. When properly adjusted, the traction drive belt should not have any movement or rotation with the engine running and park brake engaged.

9.Should movement be present, readjust traction drive belt to release belt tension as described in previous instructions.

|

| MOUNTING |

| BELT GUIDE | BRACKET |

|

| |

|

| MORE |

|

| TENSION |

| STATIONARY IDLER |

|

| STATIONARY IDLER |

|

| MOUNTING BOLT | LESS |

|

| TENSION |

|

| MORE TENSION |

|

| LESS TENSION |

|

| MOUNTING BRACKET |

|

| BELT GUIDE - MAKE CERTAIN |

|

| BELT GUIDE ORIENTATION IS |

|

| MAINTAINED. |

|

| STATIONARY IDLER |

|

| MOUNTING |

|

| BOLT |

FIGURE 4.21

25