Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any maintenance, adjustments or service with engine and blade running. STOP engine and blade. Disconnect spark plug wire and secure away from spark plug. Engine and components are HOT. Avoid serious burns, allow sufficient time for all components to cool.

4.4.1.Engine Drive Belt Replacement (Continued from Previous Page)

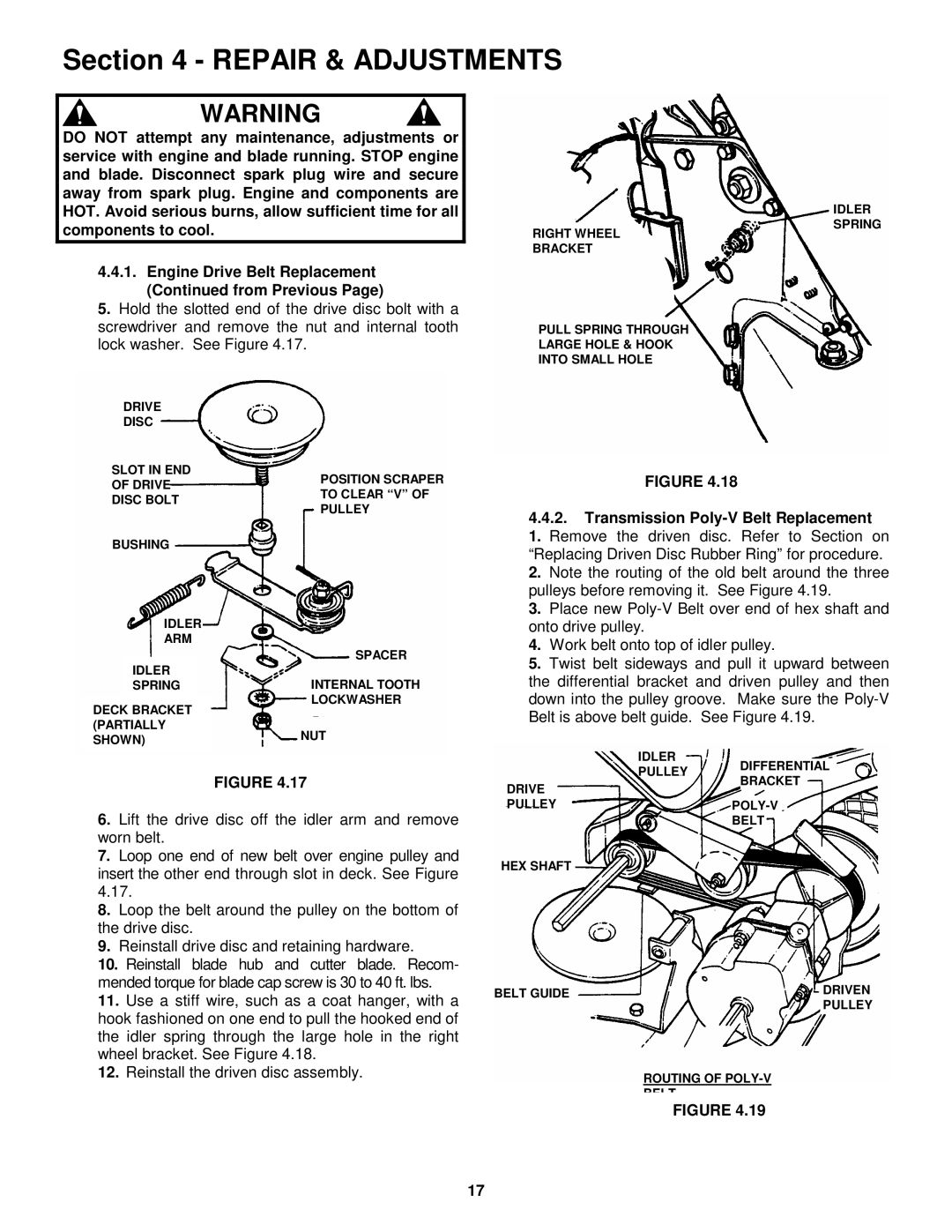

5.Hold the slotted end of the drive disc bolt with a screwdriver and remove the nut and internal tooth lock washer. See Figure 4.17.

DRIVE

DISC

SLOT IN END

OF DRIVE | POSITION SCRAPER | |

TO CLEAR “V” OF | ||

DISC BOLT | ||

PULLEY | ||

| ||

BUSHING |

|

| IDLER |

| ||

| ARM |

| ||

|

|

| SPACER | |

| IDLER |

| ||

|

| INTERNAL TOOTH | ||

| SPRING |

| ||

|

|

| LOCKWASHER | |

DECK BRACKET | ||||

| ||||

(PARTIALLY | NUT | |||

SHOWN) | ||||

| ||||

|

|

|

| |

IDLER

SPRING

RIGHT WHEEL BRACKET

PULL SPRING THROUGH

LARGE HOLE & HOOK

INTO SMALL HOLE

FIGURE 4.18

4.4.2.Transmission

3. Place new

4. Work belt onto top of idler pulley.

5. Twist belt sideways and pull it upward between the differential bracket and driven pulley and then down into the pulley groove. Make sure the

FIGURE 4.17 |

DRIVE

IDLER

PULLEY DIFFERENTIAL BRACKET

6.Lift the drive disc off the idler arm and remove worn belt.

7.Loop one end of new belt over engine pulley and insert the other end through slot in deck. See Figure

8.Loop the belt around the pulley on the bottom of the drive disc.

9.Reinstall drive disc and retaining hardware.

10.Reinstall blade hub and cutter blade. Recom- mended torque for blade cap screw is 30 to 40 ft. lbs.

11.Use a stiff wire, such as a coat hanger, with a hook fashioned on one end to pull the hooked end of the idler spring through the large hole in the right wheel bracket. See Figure 4.18.

12.Reinstall the driven disc assembly.

PULLEYPOLY-V

BELT

HEX SHAFT

BELT GUIDE | DRIVEN |

| PULLEY |

ROUTING OF

BELT

FIGURE 4.19

17