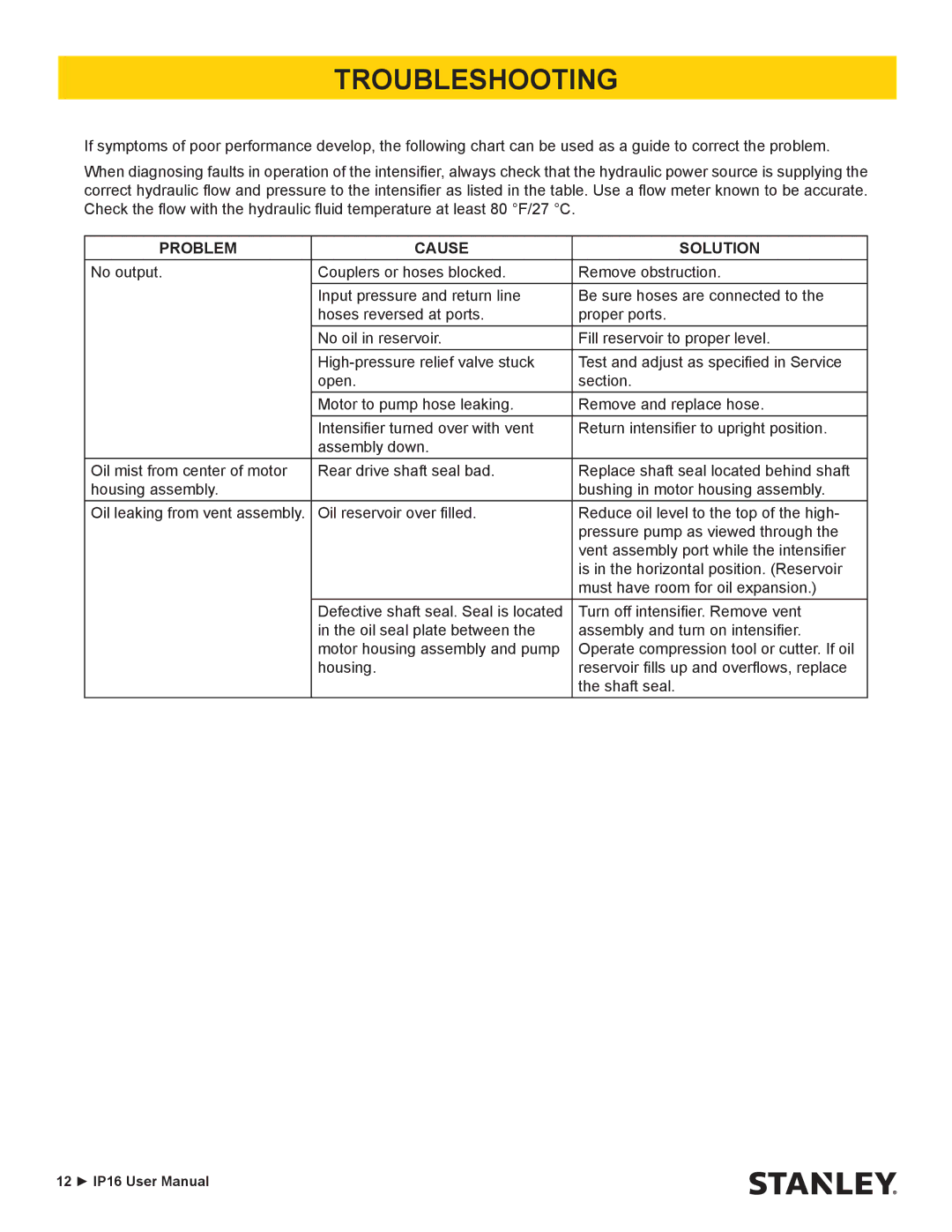

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the intensifier, always check that the hydraulic power source is supplying the correct hydraulic flow and pressure to the intensifier as listed in the table. Use a flow meter known to be accurate. Check the flow with the hydraulic fluid temperature at least 80 °F/27 °C.

PROBLEM | CAUSE | SOLUTION |

No output. | Couplers or hoses blocked. | Remove obstruction. |

| Input pressure and return line | Be sure hoses are connected to the |

| hoses reversed at ports. | proper ports. |

| No oil in reservoir. | Fill reservoir to proper level. |

| Test and adjust as specified in Service | |

| open. | section. |

| Motor to pump hose leaking. | Remove and replace hose. |

| Intensifier turned over with vent | Return intensifier to upright position. |

| assembly down. |

|

Oil mist from center of motor | Rear drive shaft seal bad. | Replace shaft seal located behind shaft |

housing assembly. |

| bushing in motor housing assembly. |

Oil leaking from vent assembly. | Oil reservoir over filled. | Reduce oil level to the top of the high- |

|

| pressure pump as viewed through the |

|

| vent assembly port while the intensifier |

|

| is in the horizontal position. (Reservoir |

|

| must have room for oil expansion.) |

| Defective shaft seal. Seal is located | Turn off intensifier. Remove vent |

| in the oil seal plate between the | assembly and turn on intensifier. |

| motor housing assembly and pump | Operate compression tool or cutter. If oil |

| housing. | reservoir fills up and overflows, replace |

|

| the shaft seal. |

12 ► IP16 User Manual