TROUBLESHOOTING

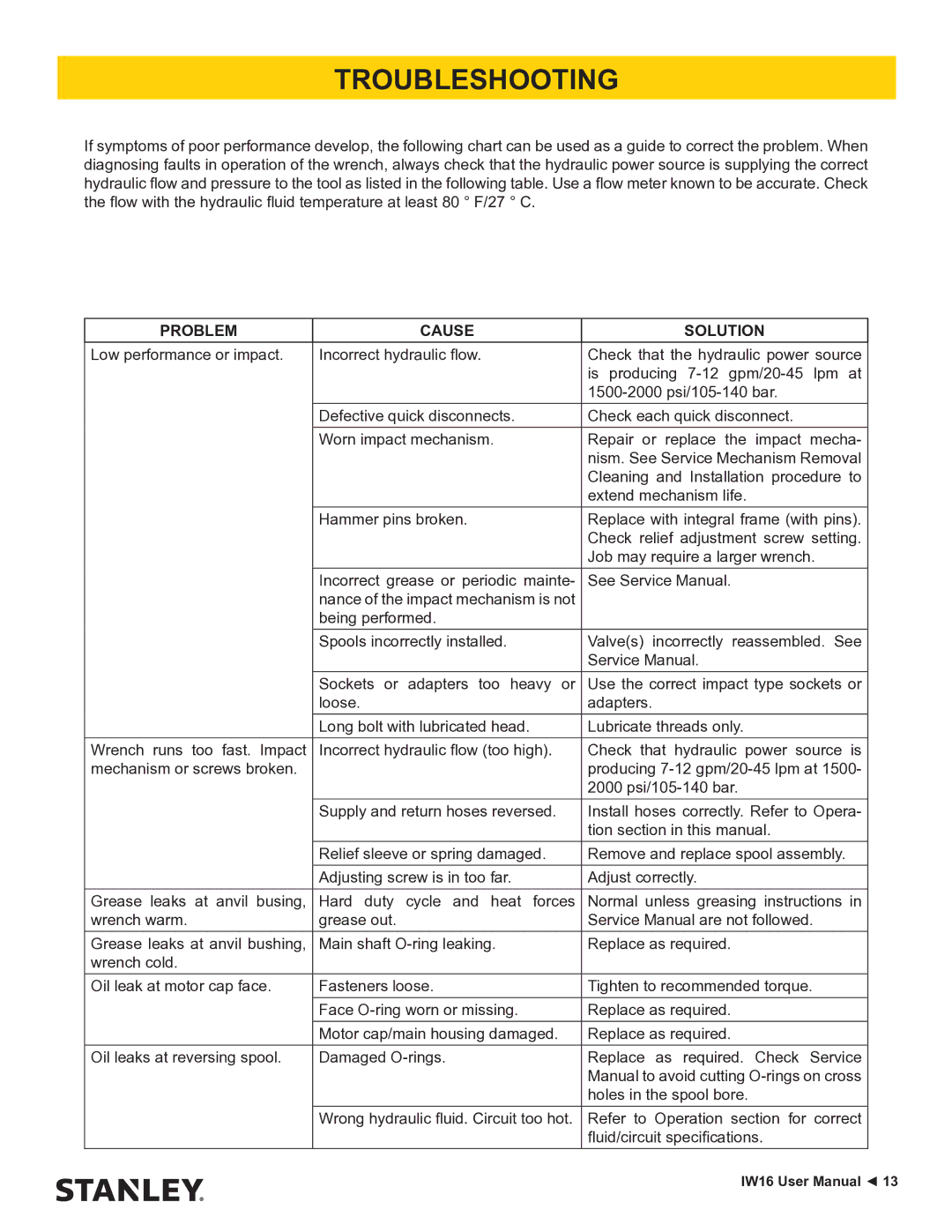

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem. When diagnosing faults in operation of the wrench, always check that the hydraulic power source is supplying the correct hydraulic flow and pressure to the tool as listed in the following table. Use a flow meter known to be accurate. Check the flow with the hydraulic fluid temperature at least 80 ° F/27 ° C.

PROBLEM

CAUSE

SOLUTION

Low performance or impact. | Incorrect hydraulic flow. | Check that the hydraulic power source |

|

|

|

| is producing |

| |

|

|

| ||

| Defective quick disconnects. | Check each quick disconnect. |

| |

| Worn impact mechanism. | Repair or replace the impact mecha- |

| |

|

| nism. See Service Mechanism Removal |

| |

|

| Cleaning and Installation procedure to |

| |

|

| extend mechanism life. |

| |

| Hammer pins broken. | Replace with integral frame (with pins). |

| |

|

| Check relief adjustment screw setting. |

| |

|

| Job may require a larger wrench. |

| |

| Incorrect grease or periodic mainte- | See Service Manual. |

| |

| nance of the impact mechanism is not |

|

|

|

| being performed. |

|

|

|

| Spools incorrectly installed. | Valve(s) incorrectly reassembled. See |

| |

|

| Service Manual. |

| |

| Sockets or adapters too heavy or | Use the correct impact type sockets or |

| |

| loose. | adapters. |

| |

| Long bolt with lubricated head. | Lubricate threads only. |

| |

Wrench runs too fast. Impact | Incorrect hydraulic flow (too high). | Check that hydraulic power source is |

| |

mechanism or screws broken. |

| producing |

| |

|

| 2000 |

| |

| Supply and return hoses reversed. | Install hoses correctly. Refer to Opera- |

| |

|

| tion section in this manual. |

| |

| Relief sleeve or spring damaged. | Remove and replace spool assembly. |

| |

| Adjusting screw is in too far. | Adjust correctly. |

| |

Grease leaks at anvil busing, | Hard duty cycle and heat forces | Normal unless greasing instructions in |

| |

wrench warm. | grease out. | Service Manual are not followed. |

| |

Grease leaks at anvil bushing, | Main shaft | Replace as required. |

| |

wrench cold. |

|

|

|

|

Oil leak at motor cap face. | Fasteners loose. | Tighten to recommended torque. |

| |

| Face | Replace as required. |

| |

| Motor cap/main housing damaged. | Replace as required. |

| |

Oil leaks at reversing spool. | Damaged | Replace as required. Check Service |

| |

|

| Manual to avoid cutting |

| |

|

| holes in the spool bore. |

| |

| Wrong hydraulic fluid. Circuit too hot. | Refer to Operation section for correct |

| |

|

| fluid/circuit specifications. |

| |

|

| IW16 User Manual ◄ 13 | ||