TROUBLESHOOTING

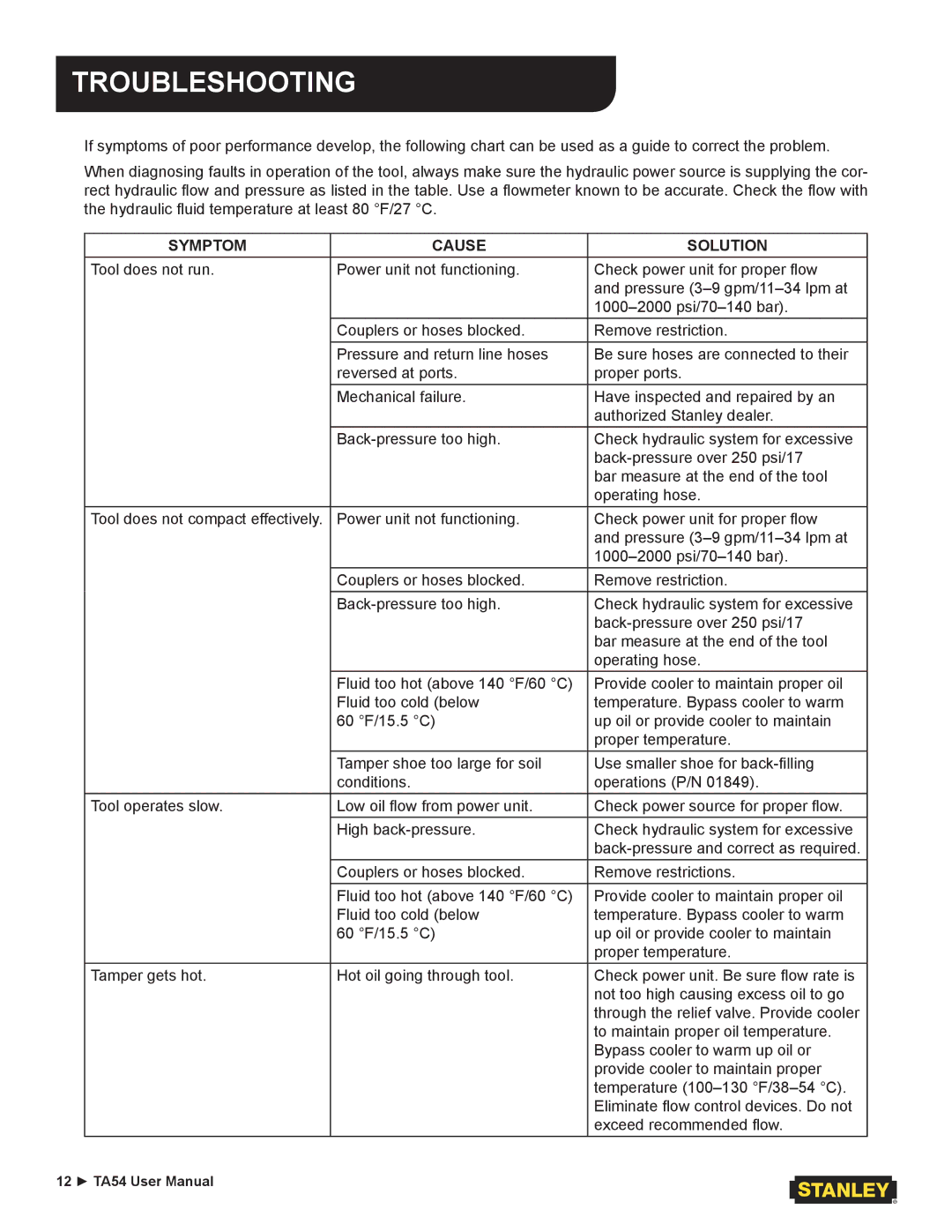

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the tool, always make sure the hydraulic power source is supplying the cor- rect hydraulic flow and pressure as listed in the table. Use a flowmeter known to be accurate. Check the flow with the hydraulic fluid temperature at least 80 °F/27 °C.

| SYMPTOM | CAUSE | SOLUTION |

| Tool does not run. | Power unit not functioning. | Check power unit for proper flow |

|

|

| and pressure |

|

|

| |

|

| Couplers or hoses blocked. | Remove restriction. |

|

| Pressure and return line hoses | Be sure hoses are connected to their |

|

| reversed at ports. | proper ports. |

|

| Mechanical failure. | Have inspected and repaired by an |

|

|

| authorized Stanley dealer. |

|

| Check hydraulic system for excessive | |

|

|

| |

|

|

| bar measure at the end of the tool |

|

|

| operating hose. |

| Tool does not compact effectively. | Power unit not functioning. | Check power unit for proper flow |

|

|

| and pressure |

|

|

| |

|

| Couplers or hoses blocked. | Remove restriction. |

|

| Check hydraulic system for excessive | |

|

|

| |

|

|

| bar measure at the end of the tool |

|

|

| operating hose. |

|

| Fluid too hot (above 140 °F/60 °C) | Provide cooler to maintain proper oil |

|

| Fluid too cold (below | temperature. Bypass cooler to warm |

|

| 60 °F/15.5 °C) | up oil or provide cooler to maintain |

|

|

| proper temperature. |

|

| Tamper shoe too large for soil | Use smaller shoe for |

|

| conditions. | operations (P/N 01849). |

| Tool operates slow. | Low oil flow from power unit. | Check power source for proper flow. |

|

| High | Check hydraulic system for excessive |

|

|

| |

|

| Couplers or hoses blocked. | Remove restrictions. |

|

| Fluid too hot (above 140 °F/60 °C) | Provide cooler to maintain proper oil |

|

| Fluid too cold (below | temperature. Bypass cooler to warm |

|

| 60 °F/15.5 °C) | up oil or provide cooler to maintain |

|

|

| proper temperature. |

| Tamper gets hot. | Hot oil going through tool. | Check power unit. Be sure flow rate is |

|

|

| not too high causing excess oil to go |

|

|

| through the relief valve. Provide cooler |

|

|

| to maintain proper oil temperature. |

|

|

| Bypass cooler to warm up oil or |

|

|

| provide cooler to maintain proper |

|

|

| temperature |

|

|

| Eliminate flow control devices. Do not |

|

|

| exceed recommended flow. |

12 ► TA54 User Manual |

|

| |