MAINTENANCE PROCEDURES

FRAMEWORK MAINTENANCE

CAUTION: DO NOT use lacquer thinner, acetone, or other solvents to clean

Framework and other structural components should be wiped down on a daily basis using a moistened with water. This will increase the longevity of protective

■Remove the packing materials, foam inserts, and ALL parts from each shipping carton. Keep the contents of each carton in a separate area to facilitate assembly. To ensure personal safety during assembly, place all packing materials outside the assembly area.

■Verify that all parts listed above are included in your shipment.

Take time now to enter your INSTINCT INNER THIGH / OUTER THIGH serial number in the space below. If parts are miss- ing, or if you have any operational questions, please call Star Trac’s Service department at (800)

Serial No. __________________________________________

tion.

Apply

Procedures to repair scratches and chips depend on the severity of the damage:

■Surface scratches can generally be repaired by polishing with an automotive rubbing compound.

■Deep scratches and chips must be repaired by filling the damaged area using a

NOTE: The process of blending and sanding repaired areas to the surrounding surface is difficult. It should be attempted ONLY by persons knowledgeable in this area.

The weight stack shrouds are made of PETG

CAUTION: Use ONLY recommended cleaning agents and procedures when cleaning the weight stack shrouds:

■DO NOT use abrasive or highly alkaline cleaners to clean the shrouds.

■DO NOT use scrape the shrouds with squeegees, razor blades or other sharp instruments. DO NOT scrub or use brushes on the shrouds.

■DO NOT use Benzene, gasoline, acetone or tetrachloride to clean the shrouds.

■DO NOT clean the shrouds in hot sun or at elevated temperatures.

ASSEMBLY

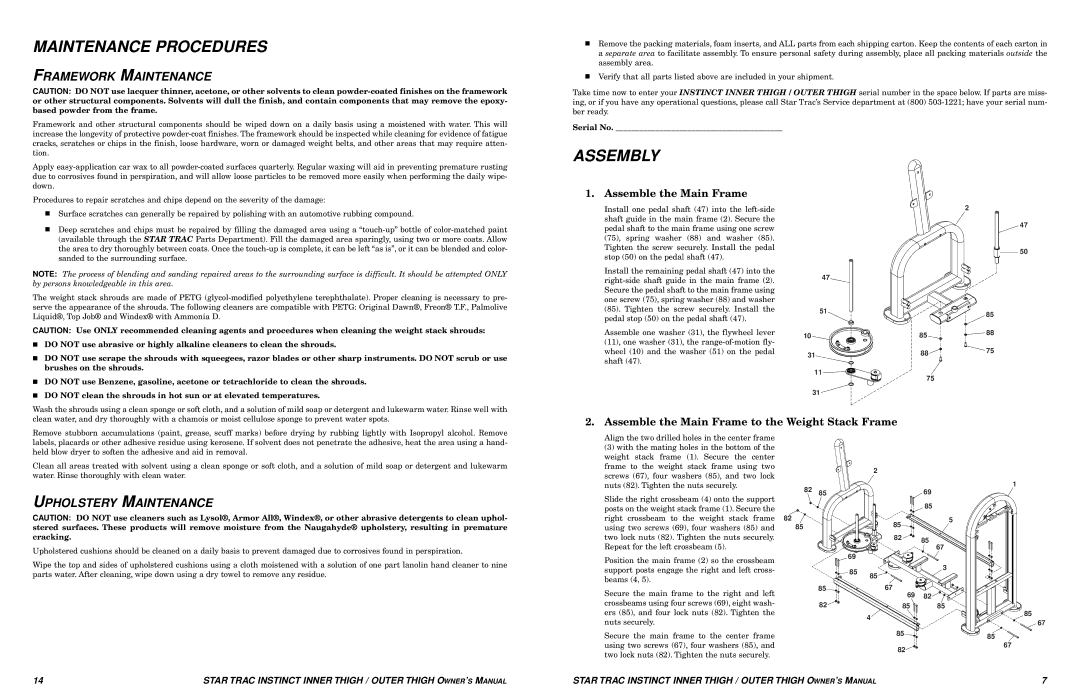

1. Assemble the Main Frame

Install one pedal shaft (47) into the

Install the remaining pedal shaft (47) into the

Assemble one washer (31), the flywheel lever (11), one washer (31), the

2

47

50

47 |

|

|

51 |

| 85 |

|

| |

10 | 85 | 88 |

| ||

31 | 88 | 75 |

| ||

11 | 75 |

|

|

| |

31 |

|

|

Wash the shrouds using a clean sponge or soft cloth, and a solution of mild soap or detergent and lukewarm water. Rinse well with clean water, and dry thoroughly with a chamois or moist cellulose sponge to prevent water spots.

2. Assemble the Main Frame to the Weight Stack Frame

Remove stubborn accumulations (paint, grease, scuff marks) before drying by rubbing lightly with Isopropyl alcohol. Remove labels, placards or other adhesive residue using kerosene. If solvent does not penetrate the adhesive, heat the area using a hand- held blow dryer to soften the adhesive and aid in removal.

Clean all areas treated with solvent using a clean sponge or soft cloth, and a solution of mild soap or detergent and lukewarm water. Rinse thoroughly with clean water.

UPHOLSTERY MAINTENANCE

CAUTION: DO NOT use cleaners such as Lysol®, Armor All®, Windex®, or other abrasive detergents to clean uphol- stered surfaces. These products will remove moisture from the Naugahyde® upholstery, resulting in premature cracking.

Upholstered cushions should be cleaned on a daily basis to prevent damaged due to corrosives found in perspiration.

Wipe the top and sides of upholstered cushions using a cloth moistened with a solution of one part lanolin hand cleaner to nine parts water. After cleaning, wipe down using a dry towel to remove any residue.

Align the two drilled holes in the center frame

(3)with the mating holes in the bottom of the weight stack frame (1). Secure the center frame to the weight stack frame using two screws (67), four washers (85), and two lock nuts (82). Tighten the nuts securely.

Slide the right crossbeam (4) onto the support posts on the weight stack frame (1). Secure the right crossbeam to the weight stack frame using two screws (69), four washers (85) and two lock nuts (82). Tighten the nuts securely. Repeat for the left crossbeam (5).

Position the main frame (2) so the crossbeam support posts engage the right and left cross- beams (4, 5).

Secure the main frame to the right and left crossbeams using four screws (69), eight wash- ers (85), and four lock nuts (82). Tighten the nuts securely.

Secure the main frame to the center frame using two screws (67), four washers (85), and two lock nuts (82). Tighten the nuts securely.

|

|

| 2 |

|

82 |

|

|

| 1 |

85 |

|

| 69 | |

|

|

| ||

|

|

|

| 85 |

82 |

|

| 85 | 5 |

85 |

|

|

| |

|

|

|

| |

|

|

| 82 | 85 |

|

|

|

| |

|

|

|

| 67 |

|

| 69 |

|

|

|

| 85 | 85 | 3 |

|

|

| ||

|

|

|

| |

| 85 |

| 67 |

|

|

|

| 69 | 82 |

| 82 |

| 85 | 85 |

4 |

| 85 |

| 67 | |

|

| |

| 85 | 85 |

|

| |

| 82 | 67 |

|

|

14 | STAR TRAC INSTINCT INNER THIGH / OUTER THIGH OWNER’S MANUAL | STAR TRAC INSTINCT INNER THIGH / OUTER THIGH OWNER’S MANUAL | 7 |