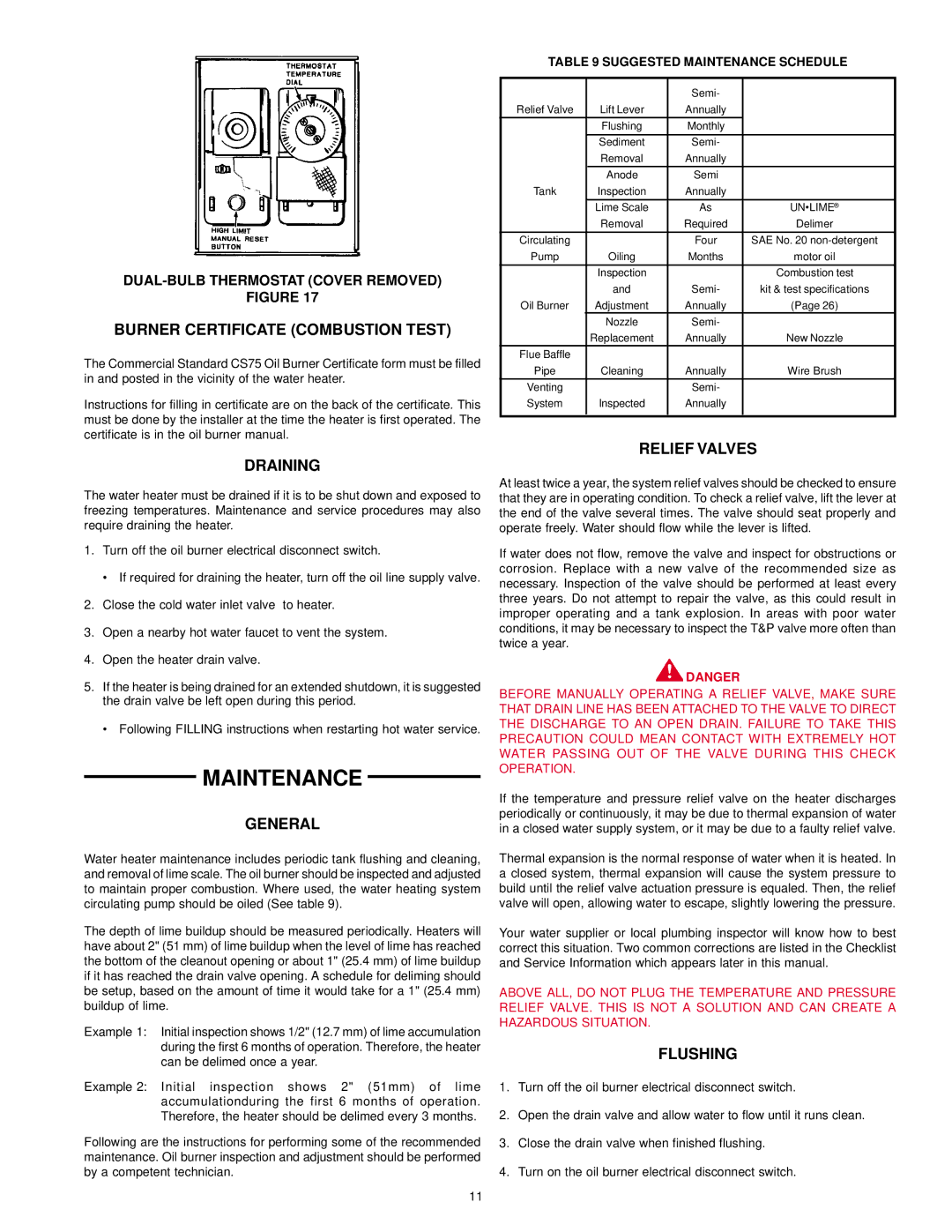

FIGURE 17

BURNER CERTIFICATE (COMBUSTION TEST)

The Commercial Standard CS75 Oil Burner Certificate form must be filled in and posted in the vicinity of the water heater.

Instructions for filling in certificate are on the back of the certificate. This must be done by the installer at the time the heater is first operated. The certificate is in the oil burner manual.

DRAINING

The water heater must be drained if it is to be shut down and exposed to freezing temperatures. Maintenance and service procedures may also require draining the heater.

1.Turn off the oil burner electrical disconnect switch.

•If required for draining the heater, turn off the oil line supply valve.

2.Close the cold water inlet valve to heater.

3.Open a nearby hot water faucet to vent the system.

4.Open the heater drain valve.

5.If the heater is being drained for an extended shutdown, it is suggested the drain valve be left open during this period.

•Following FILLING instructions when restarting hot water service.

MAINTENANCE

MAINTENANCE

GENERAL

Water heater maintenance includes periodic tank flushing and cleaning, and removal of lime scale. The oil burner should be inspected and adjusted to maintain proper combustion. Where used, the water heating system circulating pump should be oiled (See table 9).

The depth of lime buildup should be measured periodically. Heaters will have about 2" (51 mm) of lime buildup when the level of lime has reached the bottom of the cleanout opening or about 1" (25.4 mm) of lime buildup if it has reached the drain valve opening. A schedule for deliming should be setup, based on the amount of time it would take for a 1" (25.4 mm) buildup of lime.

Example 1: Initial inspection shows 1/2" (12.7 mm) of lime accumulation during the first 6 months of operation. Therefore, the heater can be delimed once a year.

Example 2: Initial inspection shows 2" (51mm) of lime accumulationduring the first 6 months of operation. Therefore, the heater should be delimed every 3 months.

Following are the instructions for performing some of the recommended maintenance. Oil burner inspection and adjustment should be performed by a competent technician.

TABLE 9 SUGGESTED MAINTENANCE SCHEDULE

|

|

| Semi- |

|

Relief Valve | Lift Lever | Annually |

| |

|

| Flushing | Monthly |

|

|

|

|

|

|

|

| Sediment | Semi- |

|

|

| Removal | Annually |

|

|

| Anode | Semi |

|

Tank | Inspection | Annually |

| |

|

|

|

|

|

|

| Lime Scale | As | UN•LIME® |

|

| Removal | Required | Delimer |

Circulating |

| Four | SAE No. 20 | |

Pump | Oiling | Months | motor oil | |

|

|

|

|

|

|

| Inspection |

| Combustion test |

|

| and | Semi- | kit & test specifications |

Oil Burner | Adjustment | Annually | (Page 26) | |

|

| Nozzle | Semi- |

|

|

| Replacement | Annually | New Nozzle |

Flue Baffle |

|

|

| |

Pipe | Cleaning | Annually | Wire Brush | |

Venting |

| Semi- |

| |

System | Inspected | Annually |

| |

|

|

|

|

|

RELIEF VALVES

At least twice a year, the system relief valves should be checked to ensure that they are in operating condition. To check a relief valve, lift the lever at the end of the valve several times. The valve should seat properly and operate freely. Water should flow while the lever is lifted.

If water does not flow, remove the valve and inspect for obstructions or corrosion. Replace with a new valve of the recommended size as necessary. Inspection of the valve should be performed at least every three years. Do not attempt to repair the valve, as this could result in improper operating and a tank explosion. In areas with poor water conditions, it may be necessary to inspect the T&P valve more often than twice a year.

![]() DANGER

DANGER

BEFORE MANUALLY OPERATING A RELIEF VALVE, MAKE SURE THAT DRAIN LINE HAS BEEN ATTACHED TO THE VALVE TO DIRECT THE DISCHARGE TO AN OPEN DRAIN. FAILURE TO TAKE THIS PRECAUTION COULD MEAN CONTACT WITH EXTREMELY HOT WATER PASSING OUT OF THE VALVE DURING THIS CHECK OPERATION.

If the temperature and pressure relief valve on the heater discharges periodically or continuously, it may be due to thermal expansion of water in a closed water supply system, or it may be due to a faulty relief valve.

Thermal expansion is the normal response of water when it is heated. In a closed system, thermal expansion will cause the system pressure to build until the relief valve actuation pressure is equaled. Then, the relief valve will open, allowing water to escape, slightly lowering the pressure.

Your water supplier or local plumbing inspector will know how to best correct this situation. Two common corrections are listed in the Checklist and Service Information which appears later in this manual.

ABOVE ALL, DO NOT PLUG THE TEMPERATURE AND PRESSURE RELIEF VALVE. THIS IS NOT A SOLUTION AND CAN CREATE A HAZARDOUS SITUATION.

FLUSHING

1.Turn off the oil burner electrical disconnect switch.

2.Open the drain valve and allow water to flow until it runs clean.

3.Close the drain valve when finished flushing.

4.Turn on the oil burner electrical disconnect switch.

11