| Micro Series Water Temperature Control Units | ||

| Reference Manual (PN: 682.89373.00) for | ||

| Complete Operation and Installation Instructions | ||

| (Available online at www.sterlco.com) | ||

|

|

| |

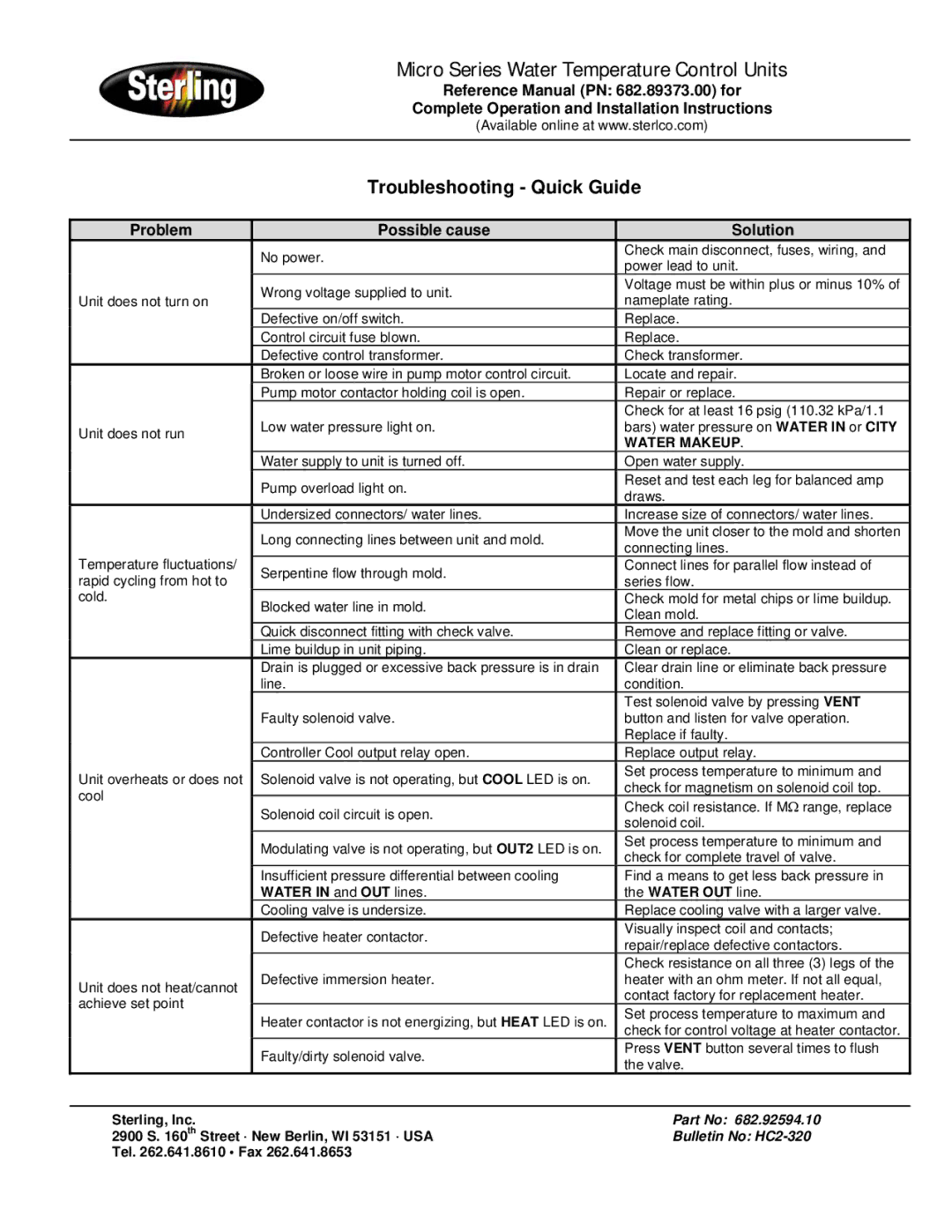

| Troubleshooting - Quick Guide | ||

|

|

| |

Problem | Possible cause | Solution | |

| No power. | Check main disconnect, fuses, wiring, and | |

| power lead to unit. | ||

|

| ||

| Wrong voltage supplied to unit. | Voltage must be within plus or minus 10% of | |

Unit does not turn on | nameplate rating. | ||

| |||

| Defective on/off switch. | Replace. | |

| Control circuit fuse blown. | Replace. | |

| Defective control transformer. | Check transformer. | |

| Broken or loose wire in pump motor control circuit. | Locate and repair. | |

| Pump motor contactor holding coil is open. | Repair or replace. | |

|

| Check for at least 16 psig (110.32 kPa/1.1 | |

Unit does not run | Low water pressure light on. | bars) water pressure on WATER IN or CITY | |

| WATER MAKEUP. | ||

|

| ||

| Water supply to unit is turned off. | Open water supply. | |

| Pump overload light on. | Reset and test each leg for balanced amp | |

| draws. | ||

|

| ||

| Undersized connectors/ water lines. | Increase size of connectors/ water lines. | |

| Long connecting lines between unit and mold. | Move the unit closer to the mold and shorten | |

| connecting lines. | ||

Temperature fluctuations/ |

| ||

Serpentine flow through mold. | Connect lines for parallel flow instead of | ||

rapid cycling from hot to | series flow. | ||

| |||

cold. |

|

| |

Blocked water line in mold. | Check mold for metal chips or lime buildup. | ||

| Clean mold. | ||

|

| ||

| Quick disconnect fitting with check valve. | Remove and replace fitting or valve. | |

| Lime buildup in unit piping. | Clean or replace. | |

| Drain is plugged or excessive back pressure is in drain | Clear drain line or eliminate back pressure | |

| line. | condition. | |

| Faulty solenoid valve. | Test solenoid valve by pressing VENT | |

| button and listen for valve operation. | ||

|

| Replace if faulty. | |

| Controller Cool output relay open. | Replace output relay. | |

Unit overheats or does not | Solenoid valve is not operating, but COOL LED is on. | Set process temperature to minimum and | |

check for magnetism on solenoid coil top. | |||

cool |

| ||

Solenoid coil circuit is open. | Check coil resistance. If MΩ range, replace | ||

| |||

| solenoid coil. | ||

|

| ||

| Modulating valve is not operating, but OUT2 LED is on. | Set process temperature to minimum and | |

| check for complete travel of valve. | ||

|

| ||

| Insufficient pressure differential between cooling | Find a means to get less back pressure in | |

| WATER IN and OUT lines. | the WATER OUT line. | |

| Cooling valve is undersize. | Replace cooling valve with a larger valve. | |

| Defective heater contactor. | Visually inspect coil and contacts; | |

| repair/replace defective contactors. | ||

|

| ||

|

| Check resistance on all three (3) legs of the | |

Unit does not heat/cannot | Defective immersion heater. | heater with an ohm meter. If not all equal, | |

| contact factory for replacement heater. | ||

achieve set point |

| ||

Heater contactor is not energizing, but HEAT LED is on. | Set process temperature to maximum and | ||

| |||

| check for control voltage at heater contactor. | ||

|

| ||

| Faulty/dirty solenoid valve. | Press VENT button several times to flush | |

| the valve. | ||

|

| ||

|

|

| |

Sterling, Inc. |

| Part No: 682.92594.10 | |

2900 S. 160th Street · New Berlin, WI 53151 · USA | Bulletin No: | ||

Tel. 262.641.8610 • Fax 262.641.8653