ENGLISH

4.Clean the paper filter by tapping it gently against a flat surface. If the filter is very dirty, replace it.

5.Clean the

6.Assemble in the reverse order.

Compressed air or

5.10 Spark plug

The spark plug(s) must be replaced every 200 hours of operation (=at every other basic service). Before disconnecting the spark plug, clean around its mounting.

Spark plug: Champion RC12YC or equivalent.

Electrode distance: 0.75 mm.

5.11 Air intake

See 19:T. The engine is

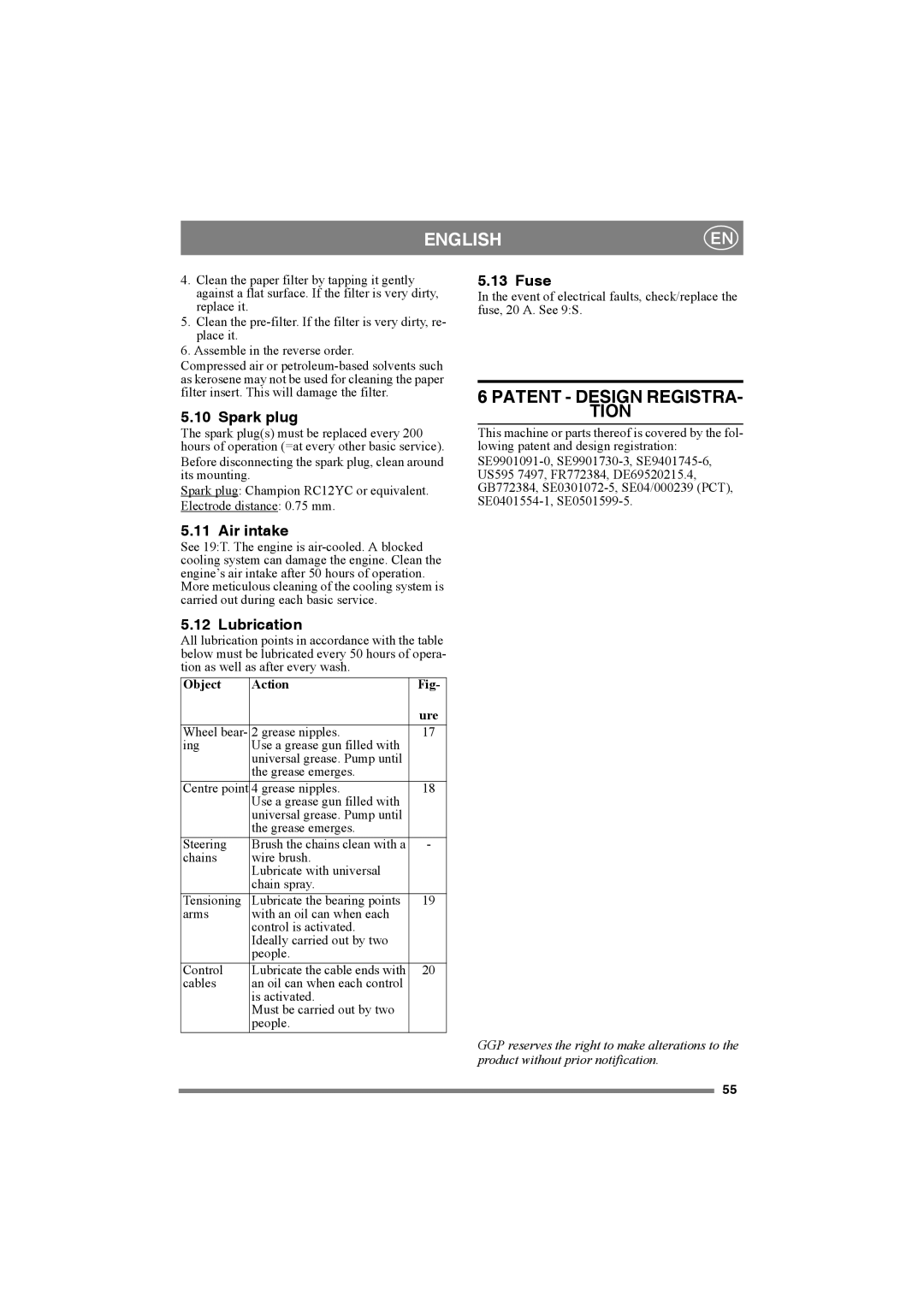

5.12 Lubrication

All lubrication points in accordance with the table below must be lubricated every 50 hours of opera- tion as well as after every wash.

Object | Action | Fig- |

|

| ure |

Wheel bear- | 2 grease nipples. | 17 |

ing | Use a grease gun filled with |

|

| universal grease. Pump until |

|

| the grease emerges. |

|

Centre point | 4 grease nipples. | 18 |

| Use a grease gun filled with |

|

| universal grease. Pump until |

|

| the grease emerges. |

|

Steering | Brush the chains clean with a | - |

chains | wire brush. |

|

| Lubricate with universal |

|

| chain spray. |

|

Tensioning | Lubricate the bearing points | 19 |

arms | with an oil can when each |

|

| control is activated. |

|

| Ideally carried out by two |

|

| people. |

|

Control | Lubricate the cable ends with | 20 |

cables | an oil can when each control |

|

| is activated. |

|

| Must be carried out by two |

|

| people. |

|

5.13 Fuse

In the event of electrical faults, check/replace the fuse, 20 A. See 9:S.

6 PATENT - DESIGN REGISTRA-

TION

This machine or parts thereof is covered by the fol- lowing patent and design registration:

GGP reserves the right to make alterations to the product without prior notification.

55