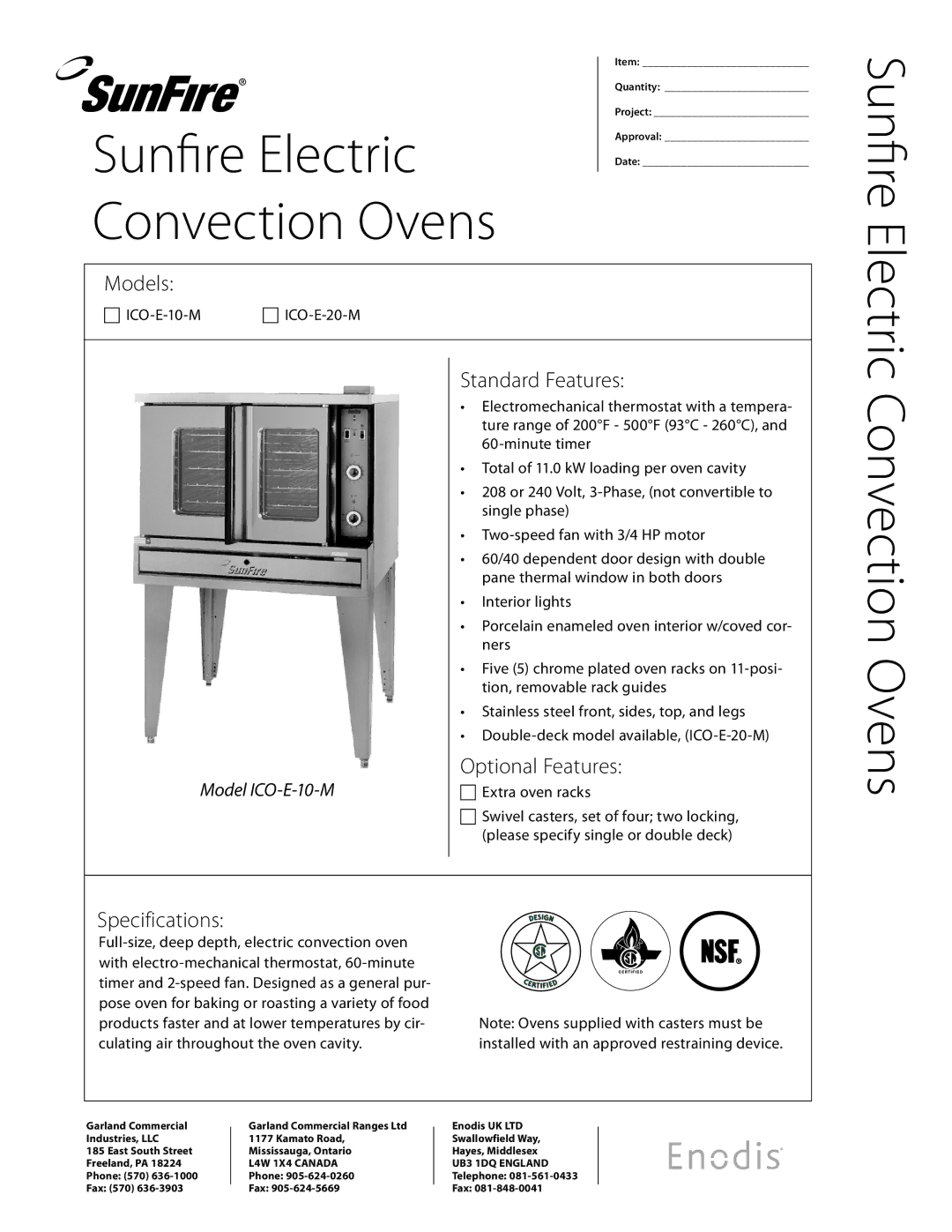

ICO-E-20-M, ICO-E-10-M specifications

The Sunfire ICO-E-10-M and ICO-E-20-M represent the latest advancements in clean energy technology, designed to meet the growing demand for efficient and eco-friendly power solutions. As part of the Sunfire series, both models prioritize high efficiency and sustainability, appealing to industries focused on reducing their carbon footprint.One of the standout features of the ICO-E series is its innovative electroklysis system, which converts renewable electricity into hydrogen. This process is crucial for energy storage and can also serve as a feedstock for various industrial applications, enhancing the versatility of hydrogen as an energy carrier. The ICO-E-10-M has a production capacity of 10 kilowatts, whereas the ICO-E-20-M offers double that, making them suitable for varying scales of energy needs, from smaller installations to larger industrial setups.

Both models employ a solid oxide electrolysis cell (SOEC) technology, which operates at high temperatures, significantly enhancing the efficiency of the hydrogen production process. By utilizing waste heat, these systems can achieve a remarkable electrical efficiency of up to 80%, setting a new standard in energy conversion. Furthermore, their ability to operate with fluctuating power inputs makes them ideal for integration with intermittent renewable energy sources like wind and solar.

Another key characteristic is their modular design, which allows for easy scaling and integration into existing energy infrastructures. This flexibility is essential for businesses looking to transition toward cleaner energy solutions without incurring heavy costs for entirely new systems. Additionally, their robust construction ensures durability and long operational life, reducing maintenance requirements and downtime.

Safety features are also paramount in the ICO-E series, with advanced monitoring systems that constantly assess operational parameters. Designed for either standalone use or as part of a larger hydrogen ecosystem, these units can contribute significantly to energy independence and sustainability goals.

In summary, the Sunfire ICO-E-10-M and ICO-E-20-M are at the forefront of clean energy technologies, combining efficiency, modularity, and eco-friendliness. As industries increasingly pivot towards sustainable practices, these systems provide a reliable solution for producing green hydrogen, supporting the transition to a low-carbon economy.