Decorative gas appliances may be installed in these fireplaces. Installation must be in accor- dance with the National Fuel Gas Code, ANSI Z223.1 for compliance with the revised U.L. 127 Standard.

CAUTION: WHEN USING A DECORATIVE GAS APPLIANCE, THE FIREPLACE DAMPER MUST BE SET TO THE FULLY OPEN POSITION.

This fireplace has been tested and approved to ANSI/IAS/AGA Z21.11.2 for use with an unvented gas appliance having a maximum rating of 26,000 BTU and complies with the Standard for Factory-Built Fireplaces, U.L. 127, when installed with unvented gas log sets. The limit may be increased to 40,000 BTU provid- ing that minimum combustible mantle heights were increased to at least 18 inches when the fireplace was installed.

Prior to installing any gas log set, (Vented or Unvented) refer to the fireplace installation instructions for verification of mantle heights and placement of combustible materials around the firebox opening. NEVER INSTALL AN

UNVENTED GAS LOG SET WITH A BTU RAT- ING GREATER THAN 26,000 IF THE COMBUSTIBLE MANTLE PROJECTIONS ARE LOWER THAN 18 INCHES ABOVE THE FIRE- PLACE OPENING. Vented gas log sets do not have restrictions placed upon their BTU rating.

Note: Units designated with the -2 suffix have not been tested or approved for use with vent free log sets.

Wood Fuel Pointers

Wood is a wonderful renewable fuel source. Normally it burns clean, leaving only a minimum of waste ash, provides comforting heat and can provide a variety of aromas and visual images.

You will want to know which woods are best for use. Sometimes you may want a quick, short fire to offset a morning chill. Soft woods are preferable in this case. Other times you would want more slow burning and a uniform heat output. Hardwoods are preferable for this use.

The amount of heat available from the logs will be about equal on a weight basis. However, logs are generally not weighed so the amount of heat will depend on:

1.The type of wood used.

2.How dry it is.

3.How many logs you put in.

4.The size of the logs.

The last statement means that one big log weighing 10 pounds has as much heating po- tential as 10 pounds of twigs. However, air cannot get at the solid log to feed the fire so the solid log will burn slowly. While you would get the same amount of heat out of either fire, the smaller the pieces of wood and the more air space around them, the faster the fire will burn.

DISPOSAL OF ASHES

Ashes should be placed in a metal container with a tight fitting lid. The closed container of ashes should be placed on a noncombustible floor or on the ground, well away from all combustible materials, pending final disposal. If the ashes are to be disposed of by burial in soil or other wise locally dispersed, they should be retained in the closed container until all cinders have thoroughly cooled.

SOFTWOOD VS HARDWOOD

Softwoods contain about 15 percent highly flammable resin which generates creosote soot in the chimney flue. Burning softwood exclu- sively may not be as desirable nor as safe as burning denser hardwoods. Many experienced fire-builders use small amounts of softwood kindling and newspaper in conjunction with starting a fire with split hardwood logs. Here are some guidelines to remember:

1.Softwoods produce fast warming and shorter fires. Hardwoods burn less vigorously, have shorter flames and produce steady, glowing coals.

2.As a general rule, denser woods contain more potential heat per pound. Most softwoods offer moderate heat value per pound.

3.Different woods vary widely in flame heights, flame intensities, smoke characteristics and in sparking. Most hardwoods do not spark.

4.Most freshly cut “green” wood will not burn well and will smoke. Green wood can be from

10to 40 percent less efficient than air-dried seasoned wood.

5.Moisture and resin found inside unseasoned wood cells will build up pressure under heat and explode as sparks.

6.Most wood needs to be seasoned 9 to 12 months to reduce the moisture content and produce good steady fires. When moisture content is reduced from 60 to 20%, the gain in heat potential is nearly 7%.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

7.Proper storage of wood, especially during seasoning, is essential. We recommend that you:

a. Never store wood on the ground. This will cause rotting and insect infiltration. Raise wood on flat rock or scrap wood.

b. Stack wood loosely to allow air circulation.

c. Store wood where it will not be excessively exposed to weather, such as under a tarp or under a roof.

d. Do not stack wood directly against the walls of your home.

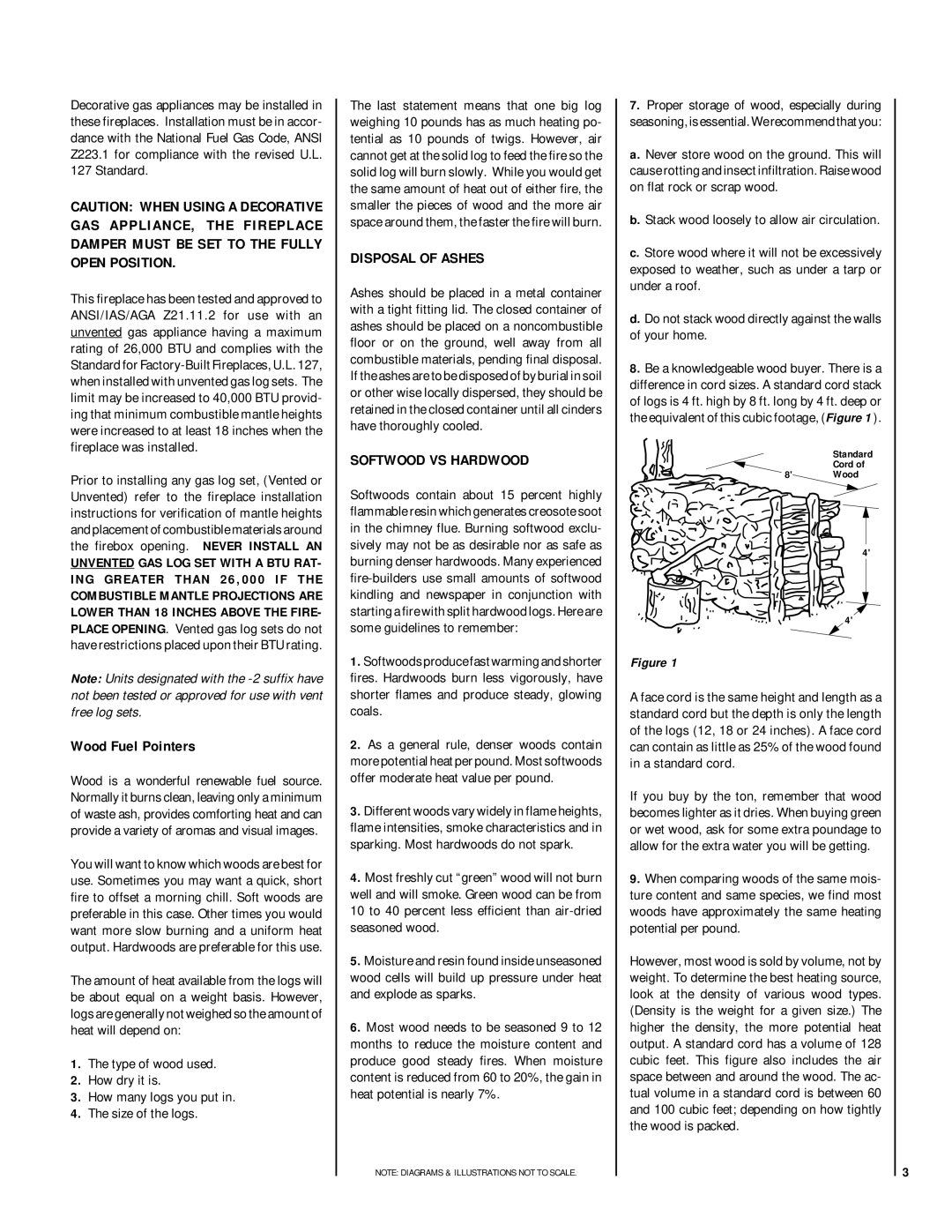

8.Be a knowledgeable wood buyer. There is a difference in cord sizes. A standard cord stack of logs is 4 ft. high by 8 ft. long by 4 ft. deep or the equivalent of this cubic footage, (Figure 1 ).

4'

4'

Figure 1

A face cord is the same height and length as a standard cord but the depth is only the length of the logs (12, 18 or 24 inches). A face cord can contain as little as 25% of the wood found in a standard cord.

If you buy by the ton, remember that wood becomes lighter as it dries. When buying green or wet wood, ask for some extra poundage to allow for the extra water you will be getting.

9.When comparing woods of the same mois- ture content and same species, we find most woods have approximately the same heating potential per pound.

However, most wood is sold by volume, not by weight. To determine the best heating source, look at the density of various wood types. (Density is the weight for a given size.) The higher the density, the more potential heat output. A standard cord has a volume of 128 cubic feet. This figure also includes the air space between and around the wood. The ac- tual volume in a standard cord is between 60 and 100 cubic feet; depending on how tightly the wood is packed.

3