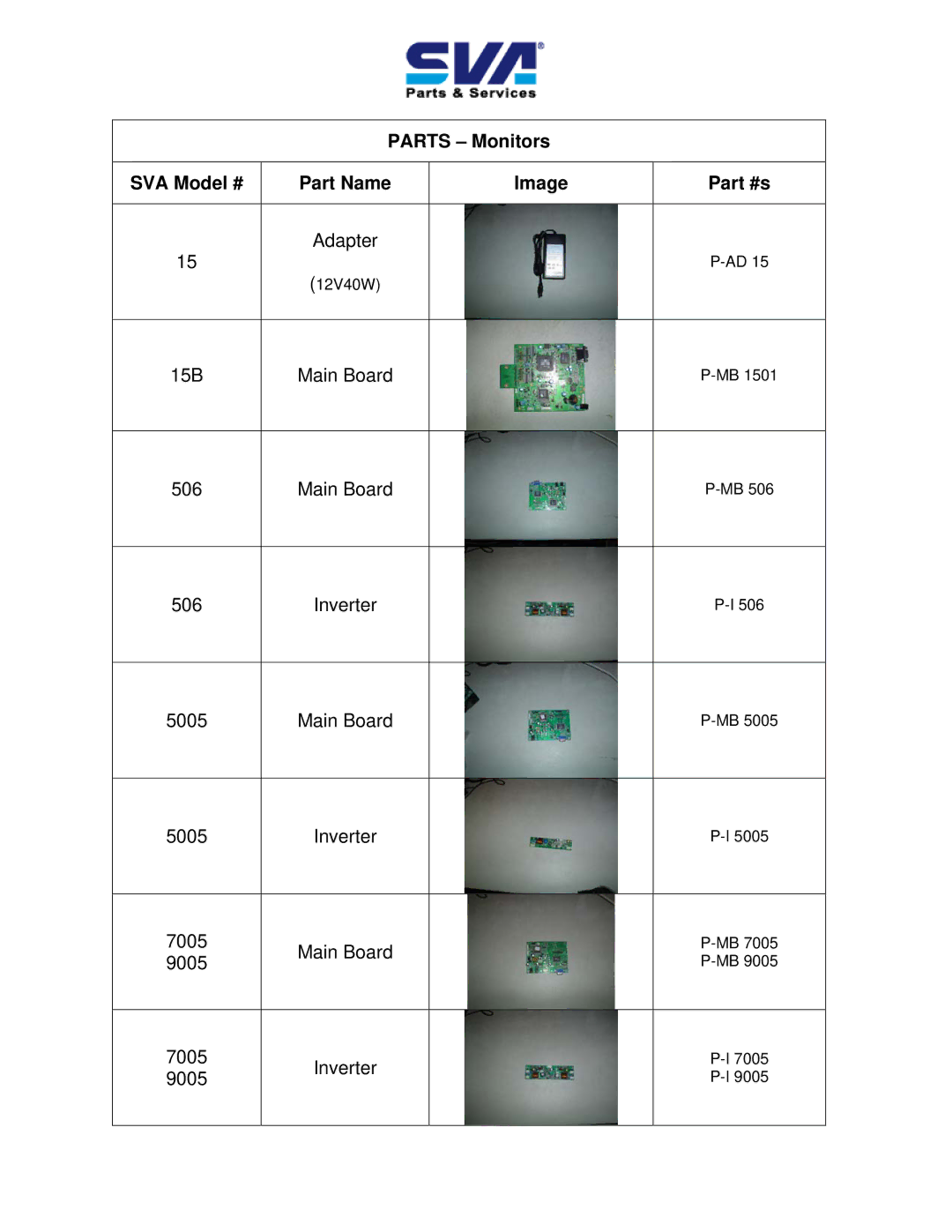

15B, 9005, 7005, 5005, 506 specifications

SVA 9005, 15B, 15, 506, and 7005 represent significant advancements in the field of structural materials, particularly favoring applications that require high strength-to-weight ratios and excellent corrosion resistance. These aluminum alloys are commonly used across various industries, including aerospace, automotive, and construction, due to their unique properties and characteristics.The SVA 9005 alloy, primarily composed of aluminum with trace elements, is renowned for its impressive tensile strength and durability. Its high resistance to fatigue and stress makes it ideal for components subjected to dynamic loads. Moreover, this alloy's excellent weldability enables the creation of complex structures with minimal loss of strength at the weld joints.

Alloy 15B is characterized by its excellent workability and formability, making it suitable for intricate shapes and designs. The combination of magnesium and silicon in its composition allows for enhanced corrosion resistance, especially in harsh environments. This alloy is often utilized in the manufacture of marine components that need to withstand saltwater exposure.

Alloy 15 is known for its lightweight nature while still providing good mechanical properties. It strikes an optimal balance between strength and ductility, making it well-suited for applications requiring both rigid structures and flexibility. The alloy's ease of machining allows for precise manufacturing processes, contributing to its popularity in various industrial applications.

The 506 alloy stands out for its exceptional electrical conductivity and thermal resistance. Primarily used in electrical and thermal applications, it helps reduce energy losses in electrical devices. The 506 alloy’s lightweight nature coupled with high thermal conductivity makes it ideal for heat exchangers and cooling components in electric vehicles.

Finally, the 7005 alloy is particularly favored for its high tensile strength and improved workability. This alloy is widely used in the production of bicycle frames and other sporting goods due to its capability to absorb shock while maintaining structural integrity. The 7005 alloy's exceptional resistance to bending and deformation under load contributes to its longevity and performance in demanding environments.

In conclusion, SVA 9005, 15B, 15, 506, and 7005 alloys encapsulate a range of properties beneficial across diverse applications. With their superior strength, corrosion resistance, and excellent mechanical characteristics, these alloys are poised to meet the challenges of modern engineering and manufacturing, driving innovations across multiple industries.