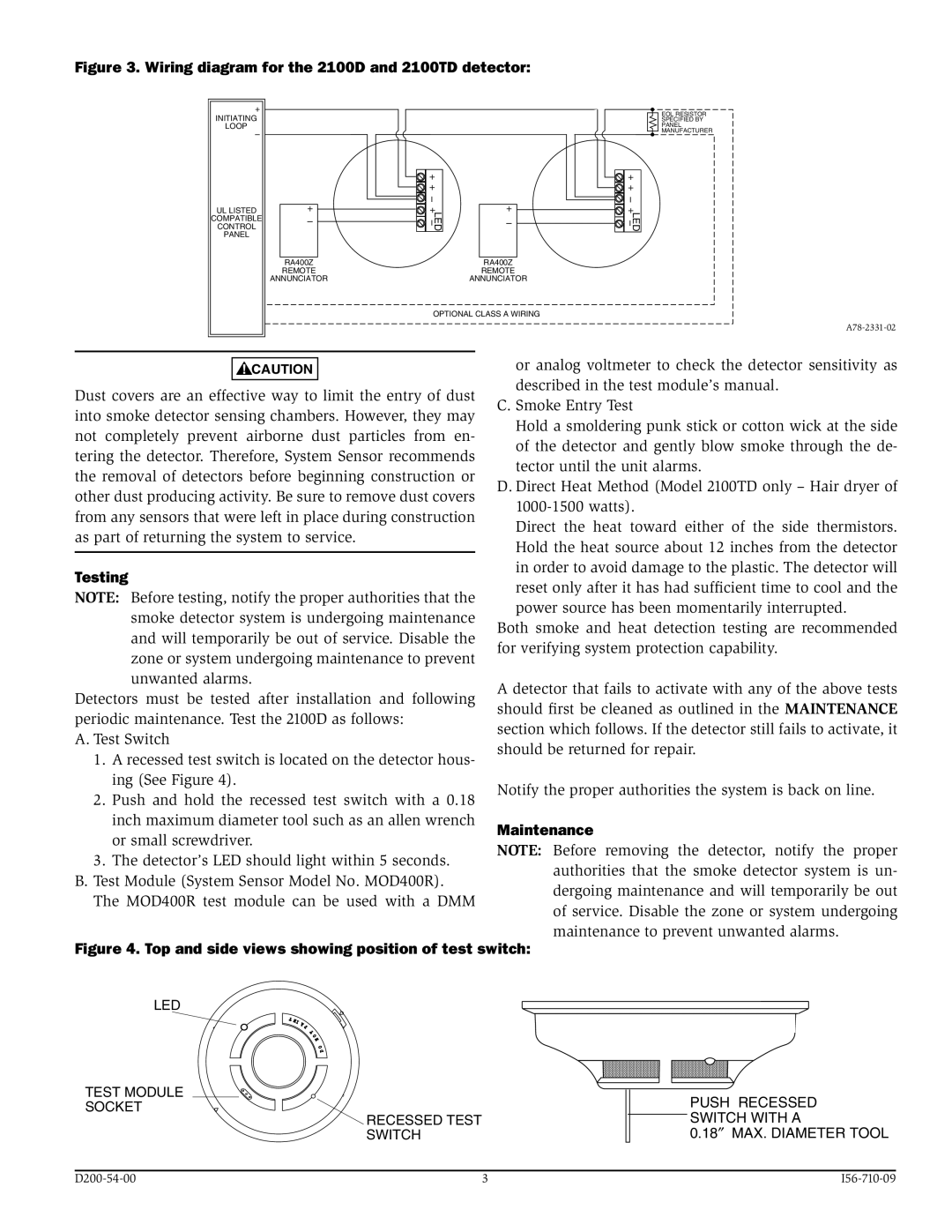

Figure 3. Wiring diagram for the 2100D and 2100TD detector:

+

INITIATING

LOOP

–

EOL RESISTOR SPECIFIED BY PANEL MANUFACTURER

UL LISTED | + |

COMPATIBLE | – |

CONTROL |

|

PANEL |

|

RA400Z

REMOTE

ANNUNCIATOR

+

+

– |

|

+ | + |

– | |

| RA400Z |

| REMOTE |

| ANNUNCIATOR |

OPTIONAL CLASS A WIRING

+

+

–

+

| CAUTION |

| or analog voltmeter to check the detector sensitivity as | ||

|

|

|

| described in the test module’s manual. | |

Dust covers are an effective way to limit the entry of dust | |||||

C. Smoke Entry Test | |||||

into smoke detector sensing chambers. However, they may | |||||

Hold a smoldering punk stick or cotton wick at the side | |||||

not completely prevent airborne dust particles from en- | |||||

of the detector and gently blow smoke through the de- | |||||

tering the detector. Therefore, System Sensor recommends | |||||

tector until the unit alarms. | |||||

the removal of detectors before beginning construction or | |||||

D. Direct Heat Method (Model 2100TD only – Hair dryer of | |||||

other dust producing activity. Be sure to remove dust covers | |||||

from any sensors that were left in place during construction | |||||

Direct the heat toward either of the side thermistors. | |||||

as part of returning the system to service. | |||||

Hold the heat source about 12 inches from the detector | |||||

|

|

|

| ||

Testing | in order to avoid damage to the plastic. The detector will | ||||

reset only after it has had sufficient time to cool and the | |||||

NOTE: Before testing, notify the proper authorities that the | |||||

power source has been momentarily interrupted. | |||||

smoke detector system is undergoing maintenance | |||||

Both smoke and heat detection testing are recommended | |||||

and will temporarily be out of service. Disable the | |||||

for verifying system protection capability. | |||||

zone or system undergoing maintenance to prevent | |||||

| |||||

unwanted alarms. | A detector that fails to activate with any of the above tests | ||||

Detectors must be tested after installation and following | |||||

should first be cleaned as outlined in the MAINTENANCE | |||||

periodic maintenance. Test the 2100D as follows: | |||||

section which follows. If the detector still fails to activate, it | |||||

A. Test Switch | |||||

should be returned for repair. | |||||

1. A recessed test switch is located on the detector hous- | |||||

| |||||

ing (See Figure 4). | Notify the proper authorities the system is back on line. | ||||

2. Push and hold the recessed test switch with a 0.18 | |||||

| |||||

inch maximum diameter tool such as an allen wrench | Maintenance | ||||

or small screwdriver. | |||||

NOTE: Before removing the detector, notify the proper | |||||

3. The detector’s LED should light within 5 seconds. | |||||

authorities that the smoke detector system is un- | |||||

B. Test Module (System Sensor Model No. MOD400R). | |||||

dergoing maintenance and will temporarily be out | |||||

The MOD400R test module can be used with a DMM | |||||

of service. Disable the zone or system undergoing | |||||

|

|

|

| ||

|

|

|

| maintenance to prevent unwanted alarms. | |

Figure 4. Top and side views showing position of test switch: | |||||

LED |

| ||||

TEST MODULE | PUSH RECESSED | |

SOCKET | ||

SWITCH WITH A | ||

RECESSED TEST | ||

SWITCH | 0.18″ MAX. DIAMETER TOOL |

3 |