THERMAL PRINTING OR INKJET PRINTING?

The REAL Facts.

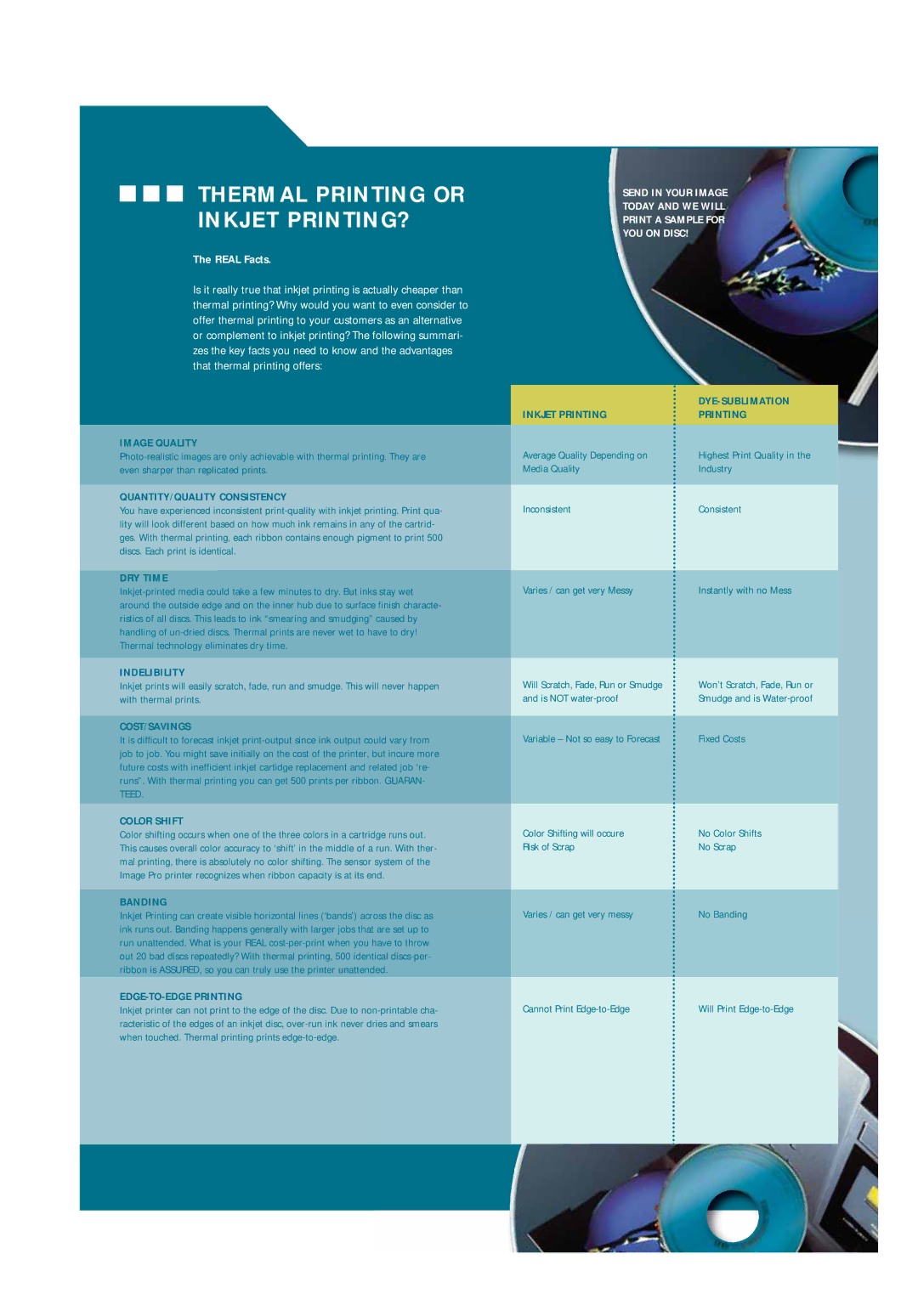

Is it really true that inkjet printing is actually cheaper than thermal printing? Why would you want to even consider to offer thermal printing to your customers as an alternative or complement to inkjet printing? The following summari- zes the key facts you need to know and the advantages that thermal printing offers:

IMAGE QUALITY

QUANTITY/QUALITY CONSISTENCY

You have experienced inconsistent

DRY TIME

INDELIBILITY

Inkjet prints will easily scratch, fade, run and smudge. This will never happen with thermal prints.

COST/SAVINGS

It is difficult to forecast inkjet

COLOR SHIFT

Color shifting occurs when one of the three colors in a cartridge runs out. This causes overall color accuracy to ‘shift’ in the middle of a run. With ther- mal printing, there is absolutely no color shifting. The sensor system of the Image Pro printer recognizes when ribbon capacity is at its end.

BANDING

Inkjet Printing can create visible horizontal lines (‘bands’) across the disc as ink runs out. Banding happens generally with larger jobs that are set up to run unattended. What is your REAL

EDGE-TO-EDGE PRINTING

Inkjet printer can not print to the edge of the disc. Due to

SEND IN YOUR IMAGE

TODAY AND WE WILL

PRINT A SAMPLE FOR

YOU ON DISC!

INKJET PRINTING |

|

PRINTING | |

Average Quality Depending on | Highest Print Quality in the |

Media Quality | Industry |

|

|

Inconsistent | Consistent |

Varies / can get very Messy | Instantly with no Mess |

Will Scratch, Fade, Run or Smudge | Won’t Scratch, Fade, Run or |

and is NOT | Smudge and is |

|

|

Variable – Not so easy to Forecast | Fixed Costs |

|

|

Color Shifting will occure | No Color Shifts |

Risk of Scrap | No Scrap |

Varies / can get very messy | No Banding |

Cannot Print | Will Print |