CAUTION

NATURAL HAZARD • SPIDERS

FACT: Sometimes spiders and other small insects climb into the burner tubes attached to the burners. The spiders spin webs, build nests and lay eggs. The webs or nests ![]() can be very small, but they are very strong

can be very small, but they are very strong ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() and can block the flow of gas. Clean

and can block the flow of gas. Clean ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() burners prior to use after storing, at the

burners prior to use after storing, at the ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() beginning of grilling season or after a period

beginning of grilling season or after a period ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() of one month not being used.

of one month not being used.![]()

![]()

![]()

![]()

![]()

![]()

![]()

Spider guards are on the air intakes in an effort to reduce this problem, but it will not eliminate it! An obstruction can result in a "flashback" (a fire in the burner tubes). The grill may still light, but the obstruction does not allow full gas flow to the burners.

IF YOU EXPERIENCE THE FOLLOWING:

1.Smell gas.

2.Burner(s) will not light.

3.A small yellow flame from burner (should be blue).

4.Fire coming from around or behind control knob.

STOP!

Immediately turn off gas at LP tank!

SOLUTION:

Wait for grill to cool.

Follow the “Cleaning The Burner Assembly” instructions. Clean burners often. Use a 12” pipe cleaner to clean out the burner tubes. You may also force a stream of water from a hose nozzle through burner tubes to clean them.

Storing Your Grill

•Clean cooking grates.

•Store in dry location.

•When LP tank is connected to grill, store outdoors in a well- ventilated space and out of reach of children.

•Cover grill if stored outdoors. Choose from a variety of grill covers offered by manufacturer.

•Store grill indoors ONLY if LP tank is turned off and disconnected, removed from grill and stored outdoors.

•When removing grill from storage, follow “Cleaning the Burner Assembly” instructions before starting grill.

Cleaning The Burner Assembly

Follow these instructions to clean and/or replace parts of burner assembly or if you have trouble igniting grill.

1.Turn gas off at control knobs and LP tank.

2.Remove cooking grates, flametamers, grease tray and grease receptacle.

3.Remove cotter pins from beneath each burner "foot" using a screwdriver or needle nose pliers.

4.Carefully lift each burner up and away from valve openings.

We suggest three ways to clean the burner tubes. Use the one easiest for you.

(A)Bend a stiff wire (a light weight coat hanger works well) into a small hook. Run the hook through each burner tube and burner several times.

(B)Use a narrow bottle brush with a flexible handle (do not use a brass wire brush), run the brush through each burner tube and burner several times.

(C)Wear eye protection: Use an air hose to force air into the burner tube and out the burner ports. Check each port to make sure air comes out each hole.

5.Wire brush entire outer surface of burner to remove food residue and dirt.

6.Clean any blocked ports with a stiff wire such as an open paper clip.

7.Check burner for damage, due to normal wear and corrosion some holes may become enlarged. If any large cracks or holes are found replace burner.

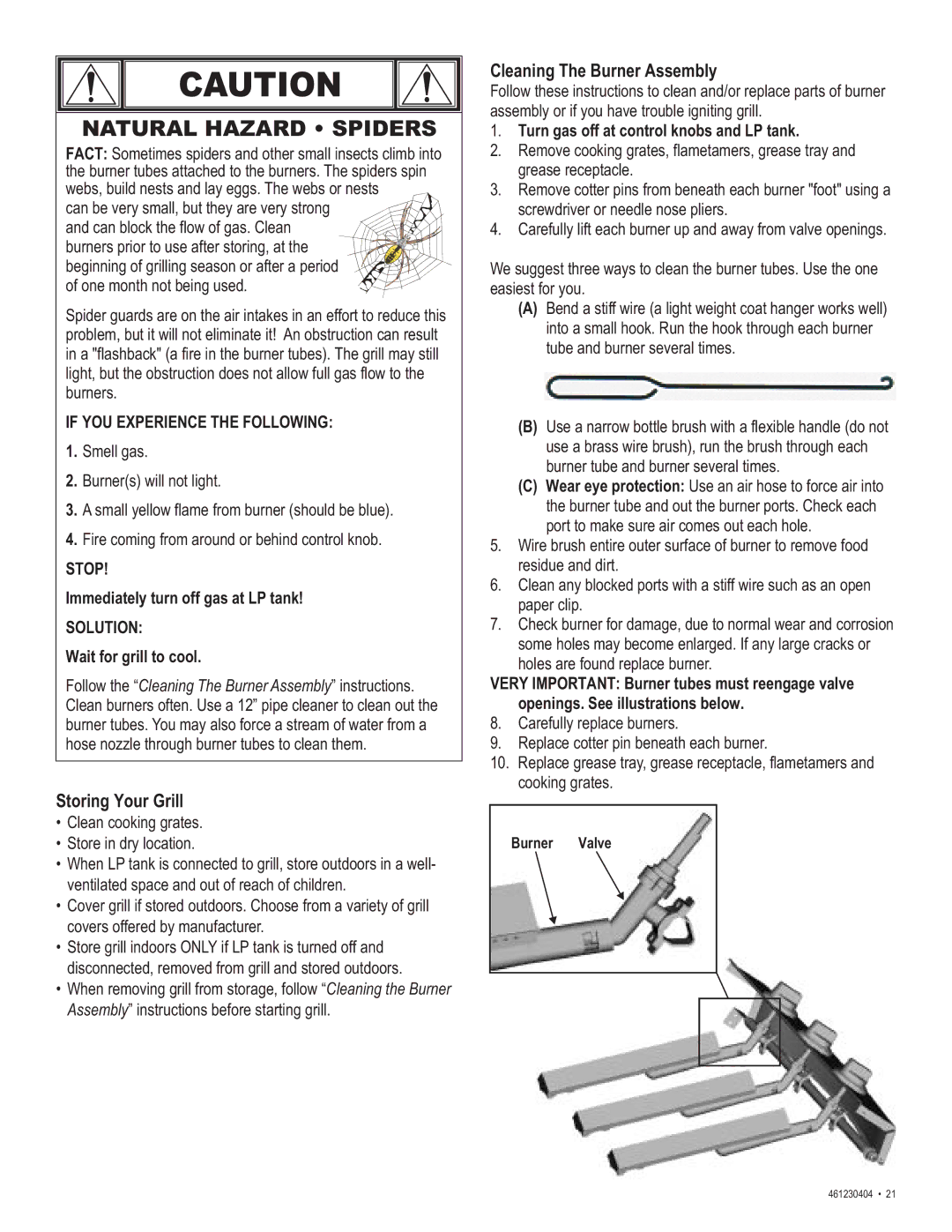

VERY IMPORTANT: Burner tubes must reengage valve openings. See illustrations below.

8.Carefully replace burners.

9.Replace cotter pin beneath each burner.

10.Replace grease tray, grease receptacle, flametamers and cooking grates.

Burner Valve

461230404 • 21