inserted the smaller end of the threads (which I filed down) into the rim of brass that was the head of the nut and peened the end down by hammering it flat so that it wouldn’t slip when it was screwed in. After the new threads were stuck tight in the rim, I drilled a hole through them, creating a threaded bushing, and eventually sized that hole to fit the escape wheel pivot. When I drilled the hole, I chucked up on the threads

instead of the rim so that I could drill the hole centered in the threads. This was important since the escape wheel turned in that hole and it was necessary that it be in the center of the threads so the escape wheel wouldn’t wobble.

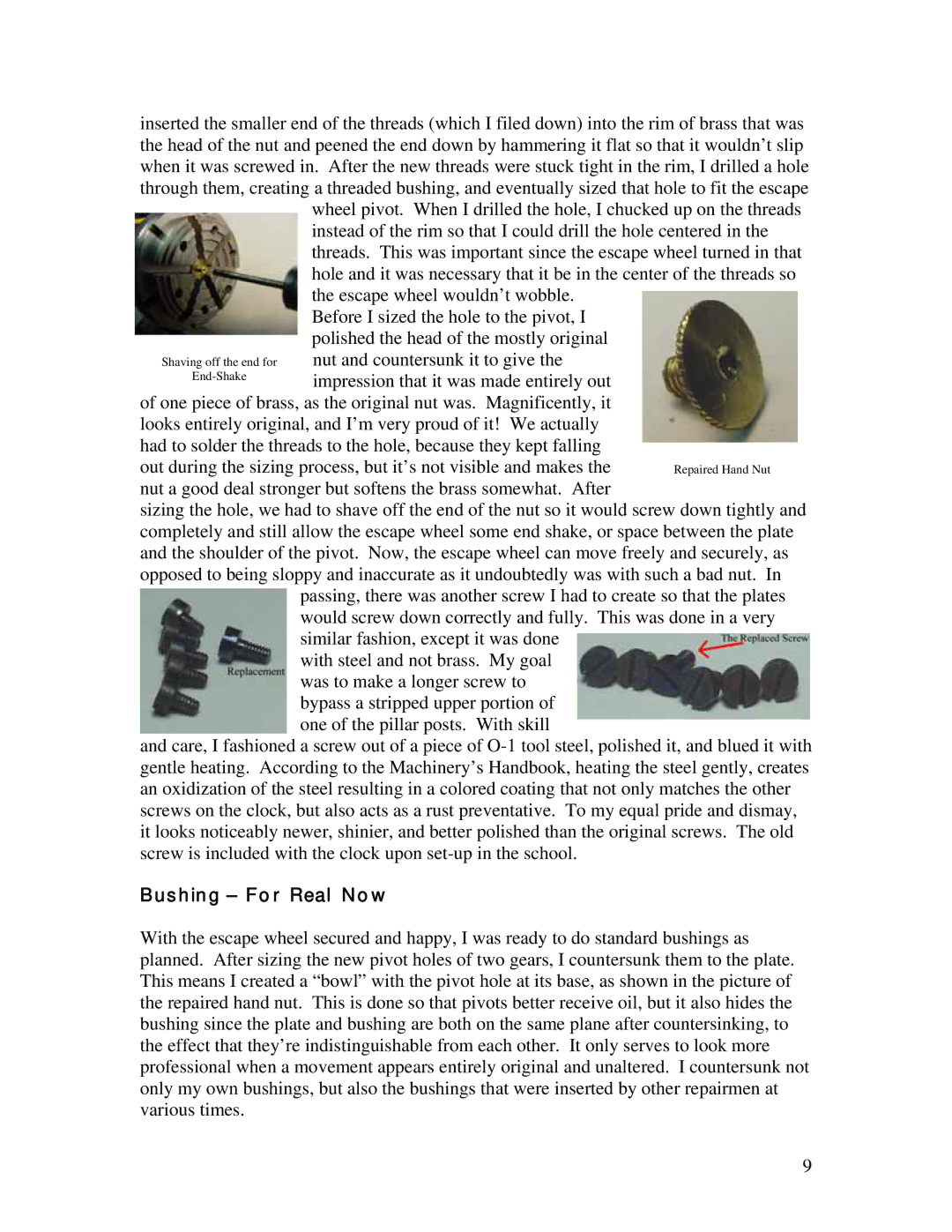

Before I sized the hole to the pivot, I polished the head of the mostly original nut and countersunk it to give the impression that it was made entirely out

of one piece of brass, as the original nut was. Magnificently, it looks entirely original, and I’m very proud of it! We actually had to solder the threads to the hole, because they kept falling out during the sizing process, but it’s not visible and makes the nut a good deal stronger but softens the brass somewhat. After

sizing the hole, we had to shave off the end of the nut so it would screw down tightly and completely and still allow the escape wheel some end shake, or space between the plate and the shoulder of the pivot. Now, the escape wheel can move freely and securely, as opposed to being sloppy and inaccurate as it undoubtedly was with such a bad nut. In

passing, there was another screw I had to create so that the plates would screw down correctly and fully. This was done in a very similar fashion, except it was done

with steel and not brass. My goal was to make a longer screw to bypass a stripped upper portion of one of the pillar posts. With skill

and care, I fashioned a screw out of a piece of

Bushing – For Real Now

With the escape wheel secured and happy, I was ready to do standard bushings as planned. After sizing the new pivot holes of two gears, I countersunk them to the plate. This means I created a “bowl” with the pivot hole at its base, as shown in the picture of the repaired hand nut. This is done so that pivots better receive oil, but it also hides the bushing since the plate and bushing are both on the same plane after countersinking, to the effect that they’re indistinguishable from each other. It only serves to look more professional when a movement appears entirely original and unaltered. I countersunk not only my own bushings, but also the bushings that were inserted by other repairmen at various times.

9