B-670 SERIES, EO1-33016E, EO1-33016 specifications

The Toshiba EO1-33016, EO1-33016E, and B-670 series are prominent offerings in Toshiba's extensive portfolio of thermal transfer printers, distinguished by their advanced features and technologies tailored for diverse industrial applications.The EO1-33016 model is engineered for reliability and performance, enabling high-quality printing solutions for labels, barcodes, and other essential identifiers. With a printing resolution of up to 300 dpi, this printer produces sharp and clear images, making it an ideal choice for businesses that demand precision. Its robust build ensures durability in challenging environments, while its easy-to-use interface allows operators of varying skill levels to navigate with ease.

Equipped with the EO1-33016E variant, users benefit from enhanced connectivity options. This model features USB, Ethernet, and Serial connectivity, facilitating seamless integration into existing workflows. The advanced processor speeds up print times, allowing for high-volume printing needs to be met efficiently. The ability to print on various materials, including paper, synthetic stocks, and specialty labels, provides versatility for different labeling needs, be it for retail, logistics, or manufacturing purposes.

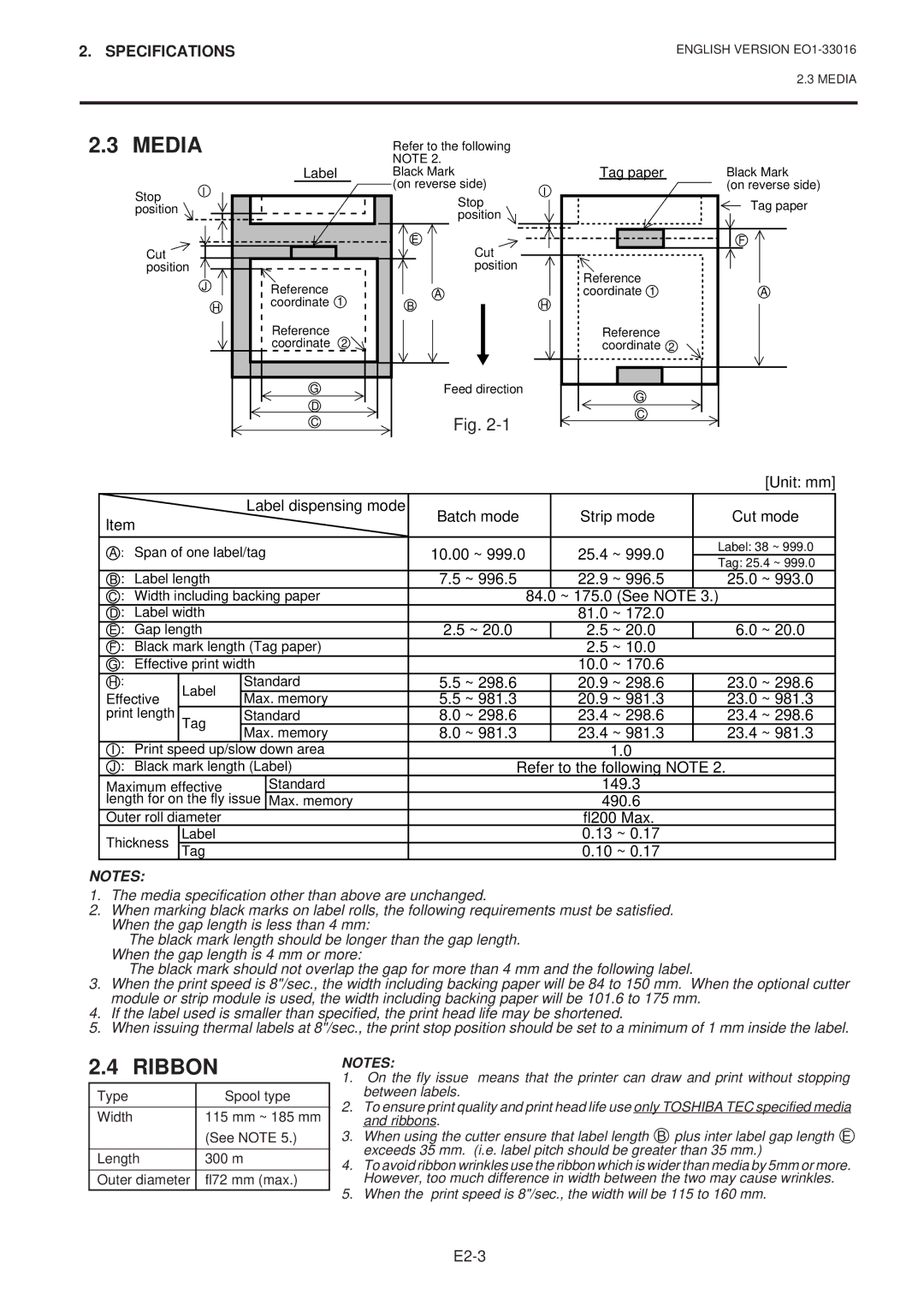

The B-670 series takes the functionality a step further by incorporating innovative thermal transfer technology. These printers support a wide range of label sizes and materials, amplifying their usability across different sectors. With sophisticated media handling capabilities, the B-670 series can accommodate various ribbon widths and lengths, thus minimizing waste and optimizing operational efficiency.

Notably, the B-670 series also features a user-friendly graphical display that simplifies printer setup and maintenance. Maintenance tasks such as ribbon and media replacements have been streamlined, allowing for quick changes to minimize downtime. Furthermore, the B-670 model is designed with energy efficiency in mind, significantly reducing the ecological footprint while maintaining high-quality output.

In summary, the Toshiba EO1-33016, EO1-33016E, and B-670 series stand out in the competitive landscape of printers due to their unique combination of reliability, advanced technologies, and user-centric designs. These models are well-suited for businesses seeking efficient and high-quality printing solutions that can adapt to a variety of labeling requirements, ensuring operational effectiveness across different applications.