Housing |

|

Screws |

|

Nozzle | Lower Housing |

Screws | |

Screws |

|

Figure 14

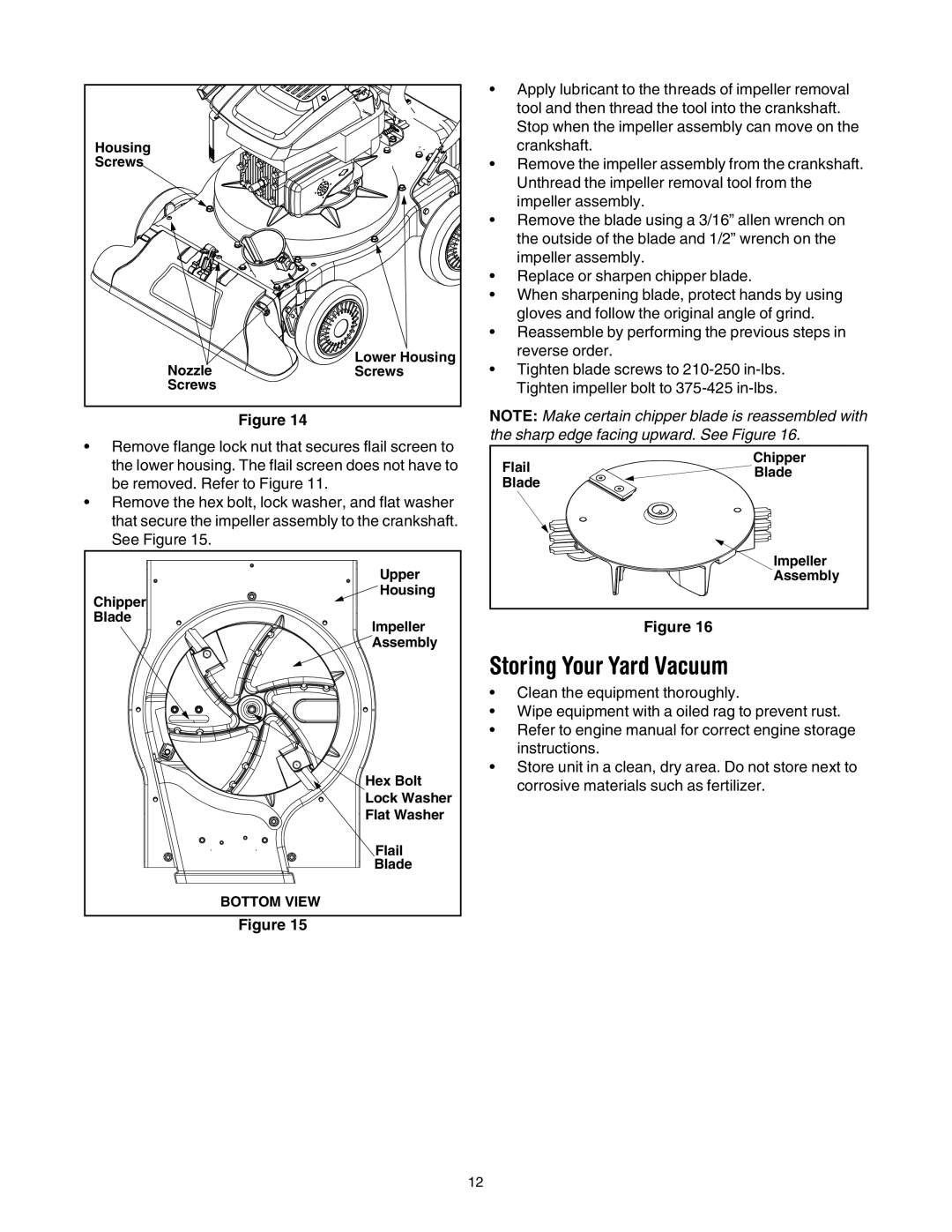

•Remove flange lock nut that secures flail screen to the lower housing. The flail screen does not have to be removed. Refer to Figure 11.

•Remove the hex bolt, lock washer, and flat washer that secure the impeller assembly to the crankshaft. See Figure 15.

Upper |

Housing |

Chipper |

Blade |

Impeller |

Assembly |

Hex Bolt |

Lock Washer |

Flat Washer |

Flail |

Blade |

BOTTOM VIEW |

Figure 15

•Apply lubricant to the threads of impeller removal tool and then thread the tool into the crankshaft. Stop when the impeller assembly can move on the crankshaft.

•Remove the impeller assembly from the crankshaft. Unthread the impeller removal tool from the impeller assembly.

•Remove the blade using a 3/16” allen wrench on the outside of the blade and 1/2” wrench on the impeller assembly.

•Replace or sharpen chipper blade.

•When sharpening blade, protect hands by using gloves and follow the original angle of grind.

•Reassemble by performing the previous steps in reverse order.

•Tighten blade screws to

NOTE: Make certain chipper blade is reassembled with the sharp edge facing upward. See Figure 16.

Flail | Chipper | |

Blade | ||

Blade | ||

| ||

| Impeller | |

| Assembly |

Figure 16

Storing Your Yard Vacuum

•Clean the equipment thoroughly.

•Wipe equipment with a oiled rag to prevent rust.

•Refer to engine manual for correct engine storage instructions.

•Store unit in a clean, dry area. Do not store next to corrosive materials such as fertilizer.

12