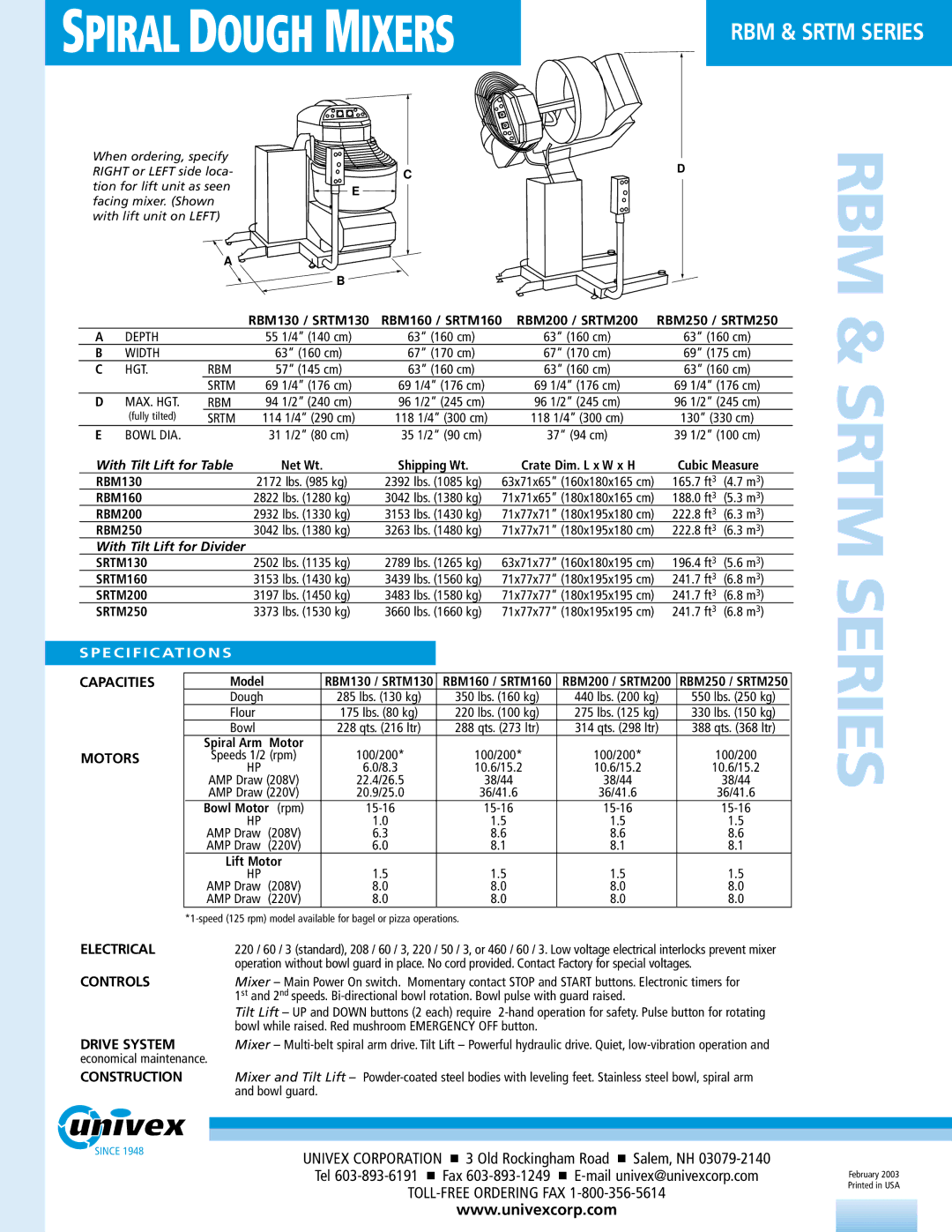

RBM, SRTM specifications

Univex SRTM and RBM are innovative solutions designed to meet the evolving needs of businesses in the food service and hospitality industries. The SRTM (Scalable Rapid Temperature Monitoring) and RBM (Real-time Business Management) systems provide cutting-edge technology that enhances operational efficiency, food safety, and customer satisfaction.One of the main features of the Univex SRTM is its advanced temperature monitoring capabilities. This system ensures that food and other perishables are stored and served at optimum temperatures, significantly reducing the risk of foodborne illnesses. The SRTM includes wireless sensor technology that provides real-time data on temperature fluctuations, enabling staff to address any issues promptly. Its customizable alerts notify managers immediately if temperatures exceed safe thresholds, allowing for quick corrective action.

The RBM component complements the SRTM by offering comprehensive management tools that streamline operations. This system is equipped with data analytics capabilities that help businesses track key performance indicators, understand consumer behavior, and identify areas for improvement. The RBM's user-friendly dashboard consolidates valuable insights, making it easier for managers to make informed decisions and enhance profitability.

In terms of technology, both systems leverage cloud-based infrastructure, providing businesses with the flexibility to access critical data from anywhere. This enables seamless integration with existing operations, ensuring that managers can monitor performance in real-time, whether they are on-site or working remotely. The systems also support mobile applications, allowing staff to receive alerts and access information on the go.

The Univex SRTM and RBM systems are characterized by their scalability, making them suitable for businesses of all sizes. Whether it's a small café or a large restaurant chain, these solutions can adapt to meet the specific requirements of any operation. Their robust security measures ensure data integrity and protect sensitive information, giving businesses peace of mind.

Overall, Univex SRTM and RBM represent a significant advancement in food safety and business management technology. With their focus on real-time monitoring, data analysis, and operational efficiency, these systems empower businesses to provide superior service while ensuring the highest food safety standards. The integration of these technologies not only enhances customer satisfaction but also drives growth and profitability in a highly competitive market.