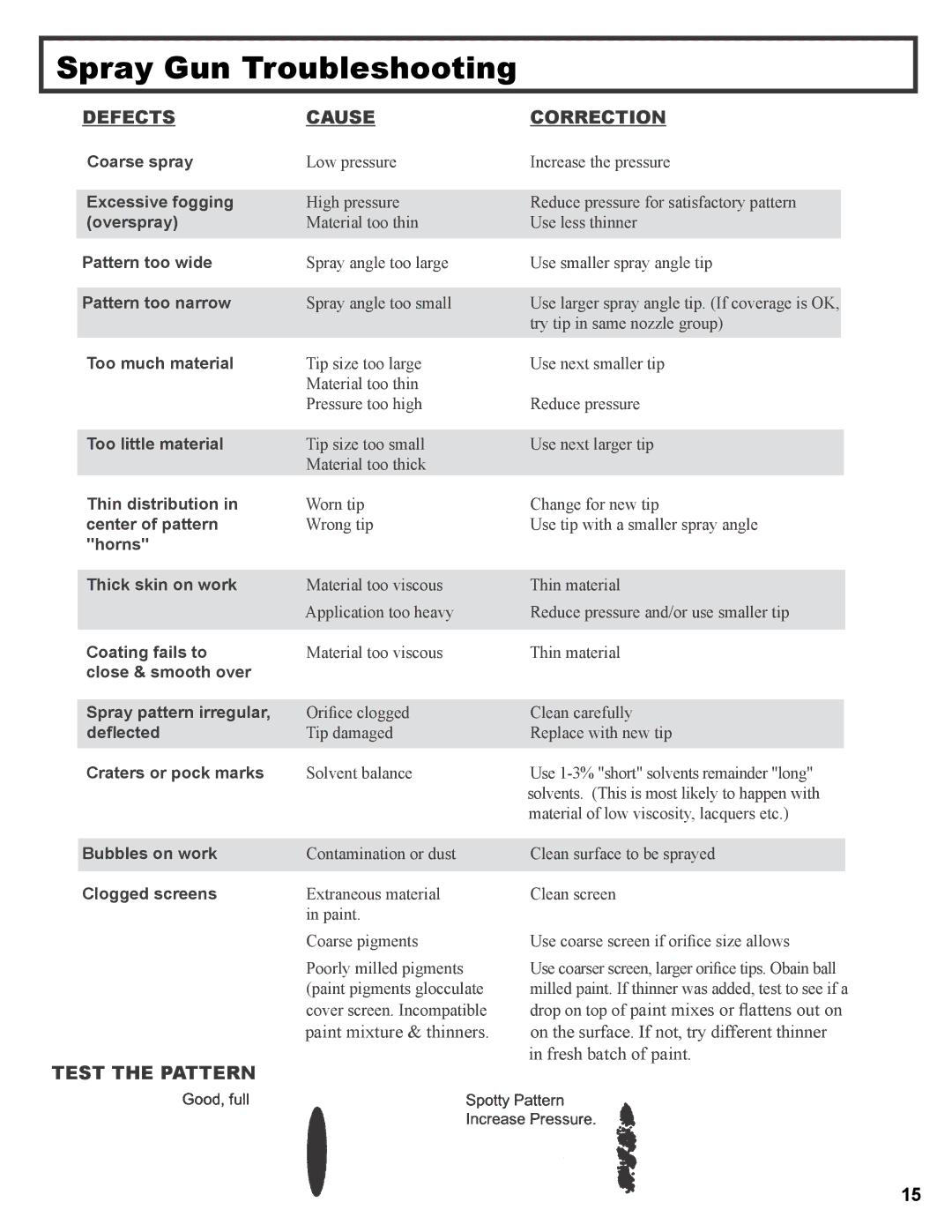

Spray Gun Troubleshooting

DEFECTS | CAUSE |

Coarse spray | Low pressure |

Excessive fogging | High pressure |

(overspray) | Material too thin |

Pattern too wide | Spray angle too large |

Pattern too narrow | Spray angle too small |

Too much material | Tip size too large |

| Material too thin |

| Pressure too high |

Too little material | Tip size too small |

| Material too thick |

Thin distribution in | Worn tip |

center of pattern | Wrong tip |

"horns" |

|

Thick skin on work | Material too viscous |

| Application too heavy |

Coating fails to | Material too viscous |

close & smooth over |

|

Spray pattern irregular, | Orifice clogged |

deflected | Tip damaged |

Craters or pock marks | Solvent balance |

Bubbles on work | Contamination or dust |

Clogged screens | Extraneous material |

| in paint. |

| Coarse pigments |

| Poorly milled pigments |

| (paint pigments glocculate |

| cover screen. Incompatible |

| paint mixture & thinners. |

TEST THE PATTERN |

|

CORRECTION

Increase the pressure

Reduce pressure for satisfactory pattern Use less thinner

Use smaller spray angle tip

Use larger spray angle tip. (If coverage is OK, try tip in same nozzle group)

Use next smaller tip

Reduce pressure

Use next larger tip

Change for new tip

Use tip with a smaller spray angle

Thin material

Reduce pressure and/or use smaller tip

Thin material

Clean carefully

Replace with new tip

Use

Clean surface to be sprayed

Clean screen

Use coarse screen if orifice size allows

Use coarser screen, larger orifice tips. Obain ball milled paint. If thinner was added, test to see if a

drop on top of paint mixes or flattens out on on the surface. If not, try different thinner in fresh batch of paint.

15