Electric Tubular Heaters specifications

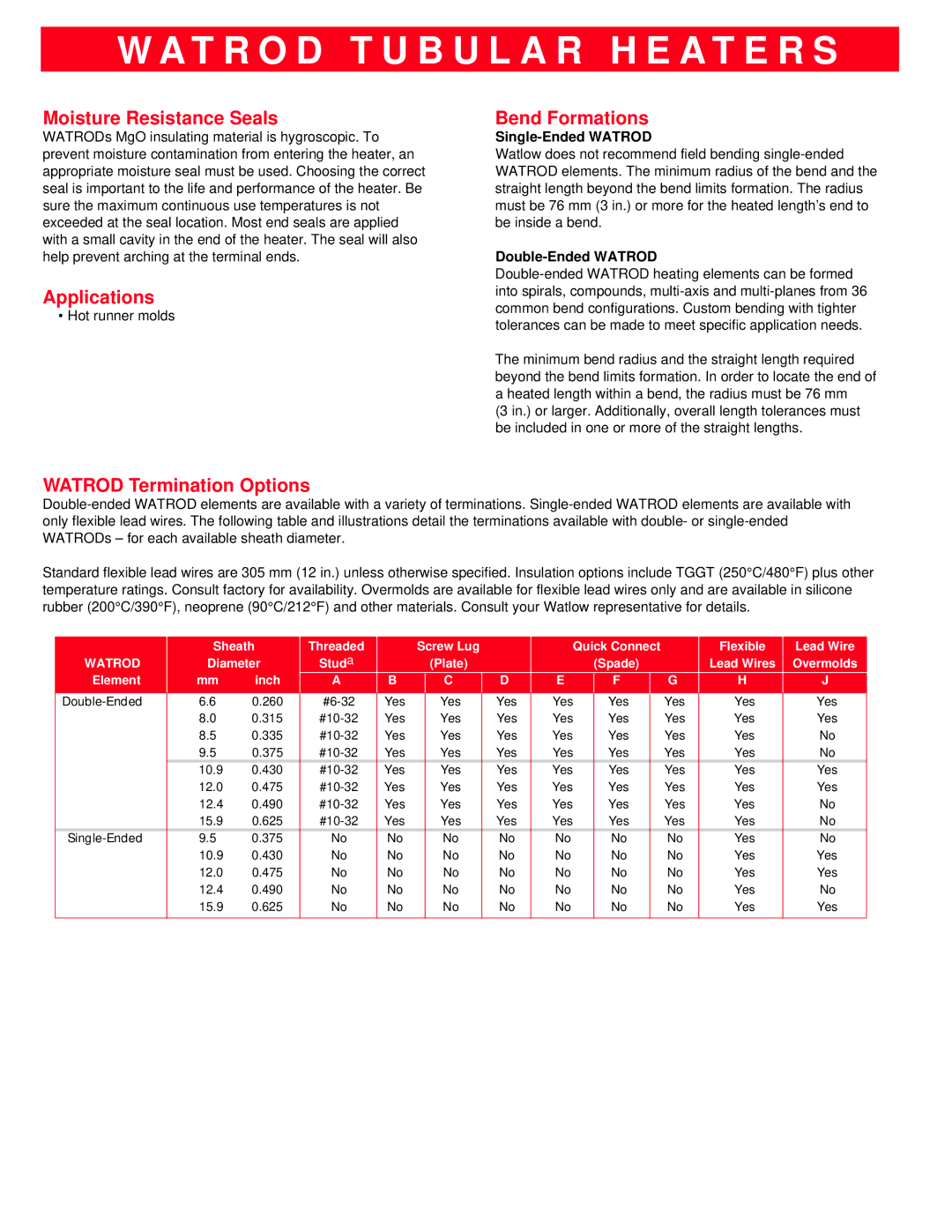

Watlow Electric is a leading manufacturer of electric tubular heaters, renowned for their innovative design and reliable performance. These heaters, also known as tubular heating elements, are versatile and can be used in a variety of industrial applications, including heating fluids, gases, and solid materials. One of the main features of Watlow's electric tubular heaters is their robust construction. Made from high-quality materials such as stainless steel or Incoloy, these heaters are designed to withstand extreme temperatures and harsh environments, ensuring long-lasting performance.Watlow's tubular heaters come in a variety of sizes and watt densities, making them suitable for numerous applications. They can be customized to meet specific requirements, including length, diameter, and termination type. This flexibility allows engineers to design systems tailored to their unique heating needs, whether in food processing, water heating, or chemical processing sectors.

One of the key technologies employed in Watlow tubular heaters is their advanced insulation and sheathing materials. This technology not only enhances the efficiency of the heating elements but also improves safety by reducing the risk of overheating and energy loss. Watlow also implements precision control technology in its heating solutions, which provides accurate temperature regulation and improved energy efficiency. This is critical in applications where temperature consistency is crucial for product quality.

Additionally, Watlow electric tubular heaters can be integrated with advanced control systems and sensors, allowing for real-time monitoring and adjustments. This modern connectivity facilitates predictive maintenance, minimizing downtime, and maximizing operational efficiency. The heaters are also designed to comply with various industry standards, ensuring they meet regulatory requirements for safety and performance.

In summary, Watlow Electric tubular heaters are recognized for their durability, customization options, and advanced technological features. With a focus on energy efficiency, precision control, and robust construction, these heaters are well-suited for a wide range of industrial applications, making them a preferred choice for manufacturers and engineers worldwide. Their commitment to innovation and quality has solidified Watlow's position as a trusted supplier in the electric heating market.