LGB-5, LGB-4 specifications

Weil-McLain has long been a respected name in the heating industry, known for their commitment to quality and efficiency. Among their impressive product line, the LGB-4 and LGB-5 steam boilers stand out as reliable choices for commercial and industrial heating applications. These boilers are designed to deliver efficient performance while maintaining ease of installation and operation.The Weil-McLain LGB-4 and LGB-5 are cast iron steam boilers, with a robust design that ensures durability and longevity. The LGB-4 has a firing range of 175 to 600 MBH (thousands of BTUs per hour), making it suitable for medium to large heating loads. The LGB-5, on the other hand, offers a firing range of 300 to 1,200 MBH, catering to larger industrial applications. This versatility allows for a wide range of configurations, making the boilers suitable for various applications in commercial buildings, schools, and healthcare facilities.

One of the prominent features of the LGB series is its Modular Design. This design allows for multiple boilers to be linked together to provide efficient heating for larger buildings. By employing multiple heating units, the system can respond more effectively to varying heating demands, resulting in reduced energy consumption and increased efficiency.

Energy efficiency is a standout characteristic of the LGB-4 and LGB-5. Both models are designed with advanced combustion technology, ensuring optimal fuel utilization and lower emissions. The cast iron construction not only provides durability but also excellent thermal mass, helping to maintain steady temperature control while reducing fuel costs. The optional low-NOx burners further minimize environmental impact, adhering to stringent emissions regulations.

Another innovative feature is the built-in venting options that allow for flexibility in installations. These boilers can be vented vertically or horizontally, providing versatile installation choices that can adapt to existing infrastructure.

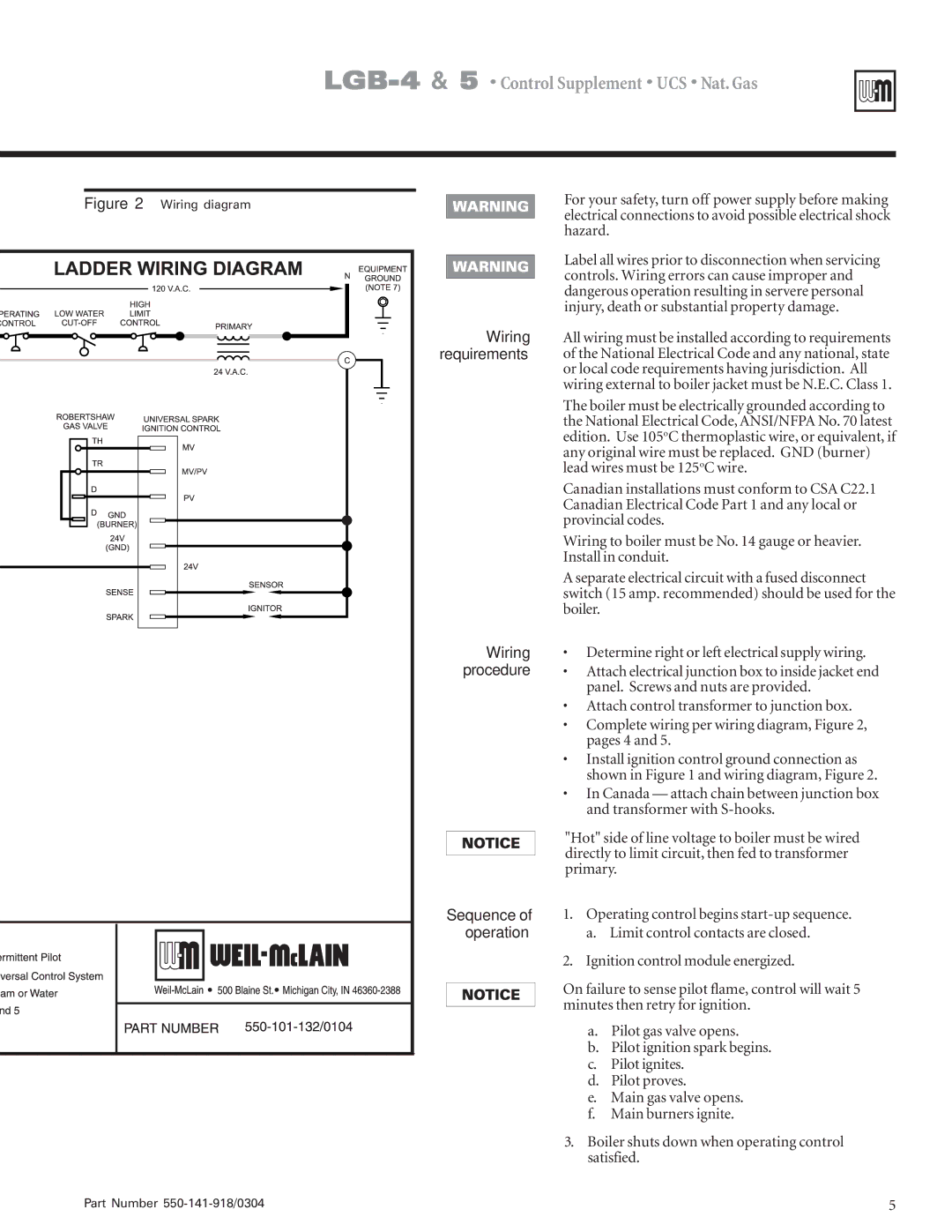

The user-friendly control panel with integrated diagnostic capabilities simplifies operation and maintenance. Features such as a standard electronic ignition system reduce manual intervention, and the modulating burner promotes more precise control of the steam output.

In summary, the Weil-McLain LGB-4 and LGB-5 steam boilers provide a combination of durability, efficiency, and flexibility. With their modular design, advanced combustion technologies, and user-friendly controls, these boilers are well-suited for a variety of commercial and industrial heating needs, ensuring reliable performance and peace of mind for building managers and facility operators.