D n Provide a gas supply line of 3/4” rigid pipe to the range location. -A smaller size- pipe on long runs may result in insufficient gas supply. Pipe-joint compounds made for use with L.P. gas must be used. With L.P. gas, piping or tubing size can be l/2” minimum. L.P. gas suppliers usually determine the size and materials used on the system.

E

In If local codes permit, a new

A.G.A.design-certified, 4 - 5 foot long,1 12” or 3/4” I.D., flexible metal appliance connector

is recommended for connecting this range to the gas supply line. Do Not kink or damage the flexible tubing when moving the range. A l/2-inch male pipe thread is needed for connecti

regulator female pipe thre

L

rm The supply line shall be equipped with an approved shutoff valve. This valve should be located in the same room as the range and should be in a location that allows ease of opening and closing. Do Not block access to shutoff valve.

G n If rigid pipe is u line, a combination of pi

used to obtain an in-line connec

range. All strains must be removed from the supply and fuel lines so range will be level and in line.

H n The reaulator must be checked at a minimum of 1-inch water column above the set pressure. The inlet pressure to the regulator should be as follows for operation:

NATURAL GAS:

Set pressure 5 inches Maximum pressure 14 inches

L.P. GAS:

Set pressure 11 inches Maximum pressure 14 inches

I n Line pressure testing:

Testing above l/2 lb psi (gauge)

The range and its individual shutoff valve

must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures greater than l/2 psig (3.5 kPa).

Testing at l/2 lb psi (gauge)

The range must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than l/2 psig (3.5 kPa).

Electrical

Requirements

Electrical Shock Hazard

. Electrical ground is required on this appliance.

Recommended grounding method

DO NOT, UNDER ANY CIRCUMSTANCES,

REMOVE THE POWER SUPPLY CORD | |

GROUNDING | | PRONG. | | | | |

For personal | | safety, | this appliance | is | |

equipped | with | a power supply cord having |

a 3-prong | grounding | plug. | To minimize | |

possible shock hazard, the cord must be | |

plugged into a mating 3-prong, grounding- | |

type | wall | receptacle, | grounded | | in | |

accordance | | with the National | | Electrical | |

Code, | ANSVNFPA | 70-latest edition* and ~;~#“s-h/pe |

all local | codes | and | ordinances. | | (See | wall receptacle |

Figure 1.) If a mating wall | | | | |

receptacle | | is not available, | it | grou | |

is the | personal | | responsibility | | | | |

and | obligation | | of the | | | | |

customer | to | have | a | | | | |

properly | grounded, | 3- | | | | |

prong | wall | receptacle | | | | |

installed | by | a | qualified | | | grounding |

| | | | | | | | |

electrician.prow

Now start...

With range in kitchen.

I n Remove shipping materials, tape and protective film from range. Keep cardboard shipping base under range. Remove oven racks and shipping materials from inside oven.

2 n Adjust the leveling legs to a point where the range base does not touch the floor.

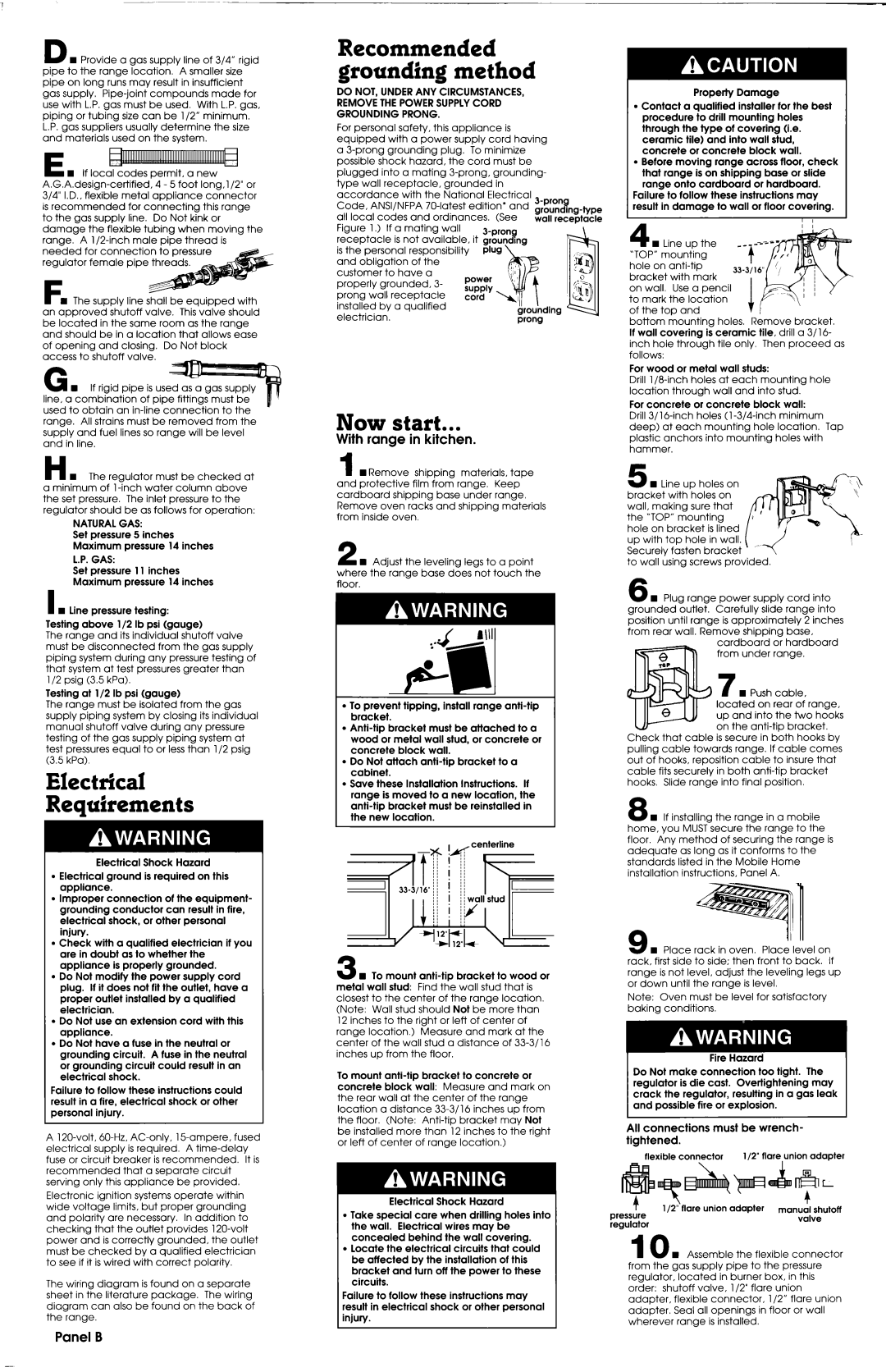

l To prevent tipping, install range anti-tip bracket.

l Anti-tip bracket must be attached to a wood or metal wall stud, or concrete or concrete block wall.

l Do Not attach anti-tip bracket to a cabinet.

l Save these Installation Instructions. If range is moved to a new location, the anti-tip bracket must be reinstalled in the new location.

Property Damage

9 Contact a qualified installer for the best procedure to drill mounting holes through the type of covering (i.e. ceramic tile) and into wall stud, concrete or concrete block wall.

. Before moving range across floor, check that range is on shipping base or slide range onto cardboard or hardboard.

Failure to follow these instructions may result in damage to wall or floor covering.

4 n Line up the “TOP” mounting hole on anti-tip bracket with mark on wall. Use a pencil to mark the location of the top and

bottom mounting holes. Remove bracket. If wall covering is ceramic tile, drill a 3/ 16- inch hole through tile only. Then proceed as follows:

For wood or metal wall studs:

Drill 1/&inch holes at each mounting hole location through wall and into stud.

For concrete or concrete block wall: Drill 3/l 6-inch holes (l -3/4-inch minimum deep) at each mounting hole location. Tap plastic anchors into mounting holes with hammer.

5n Line up holes on bracket with holes on wall, making sure that the ‘TOP” mounting hole on bracket is lined

up with top hole in wall. ( _.

Securely fasten bracket 4 to wall using screws provided.

6 n Plug range power supply cord into grounded outlet. Carefully slide range into

position until range is approximately 2 inches from rear wall. Remove shipping base,

cardboard or hardboard from under range.

7 n Push cable,

located on rear of range, up and into the two hooks on the anti-tip bracket.

Check that cable is secure in both hooks by pulling cable towards range. If cable comes out of hooks, reposition cable to insure that cable fits securely in both anti-tip bracket hooks. Slide range into final position.

8 n If installing the range in a mobile home, you MUST-secure the range to the floor. Any method of securing the range is adequate as long as it conforms to the standards listed in the Mobile Home installation instructions, Panel A.

. Improper connection of the equipment- grounding conductor can result in fire, electrical shock, or other personal injury.

. Check with a qualified electrician if you are in doubt as to whether the appliance is properly grounded.

l Do Not modify the power supply cord plug. If it does not fit the outlet, have a proper outlet installed by a qualified electrician.

l Do Not use an extension cord with this appliance.

l Do Not have a fuse in the neutral or grounding circuit. A fuse in the neutral or grounding circuit could result in an electrical shock.

Failure to follow these instructions could result in a fire, electrical shock or other personal injury.

| | | | | | |

A 120-volt, 60-Hz, AC-only, | 15-ampere, | fused |

electrical | supply | is required. | A time-delay |

fuse or | circuit | breaker | is recommended. | It is |

recommended | | that | a separate circuit | |

serving | only | this | appliance | be provided. | |

Electronic ignition systems operate within wide voltage limits, but proper grounding and polarity are necessary. In addition to checking that the outlet provides 120-volt power and is correctly grounded, the outlet must be checked by a qualified electrician to see if it is wired with correct polarity.

The wiring diagram is found on a separate

sheet in the literature package. The wiring diagram can also be found on the back of the range.

c

3 n To mount anti-tip bracket to wood or metal wall stud: Find the wall stud that is closest to the center of the range location. (Note: Wall stud should Not be more than 12 inches to the right or left of center of range location.) Measure and mark at the center of the wall stud a distance of 33-3/ 16 inches up from the floor.

To mount anti-tip bracket to concrete or concrete block wall: Measure and mark on the rear wall at the center of the range location a distance 33-3/16 inches up from the floor. (Note: Anti-tip bracket may Not be installed more than 12 inches to the right or left of center of range location.)

Electrical Shock Hazard

. Take special care when drilling holes into the wall. Electrical wires may be concealed behind the wall covering.

l Locate the electrical circuits that could be affected by the installation of this bracket and turn off the power to these circuits.

Failure to follow these instructions may result in electrical shock or other personal injury.

9 n Place rack in oven. Place level on rack, first side to side; then front to back. If range is not level, adjust the leveling legs up or down until the range is level.

Note: Oven must be level for satisfactory baking conditions.

Do Not make connection too tight. The

regulator is die cast. Overtightening may crack the regulator, resulting in a gas leak and possible fire or explosion.

All connections must be wrench- tightened.

flexible connector | l/2” flare union adapter |

10 n Assemble the flexible connector from the gas supply pipe to the pressure regulator, located in burner box, in this order: shutoff valve, l/2” flare union adapter, flexible connector, l/2” flare union adapter. Seal all openings in floor or wall wherever range is installed.