Electrical Requirements

If codes permit and a separate ground wire is used, it is recommended that a qualified electrical installer determine that the ground path and wire gauge are in accordance with local codes.

Check with a qualified electrical installer if you are not sure the oven is properly grounded.

This oven must be connected to a grounded metal, permanent wiring system.

Be sure that the electrical connection and wire size are adequate and in conformance with the National Electrical Code, ANSI/NFPA

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

Electrical Connection

To properly install your oven, you must determine the type of electrical connection you will be using and follow the instructions provided for it here.

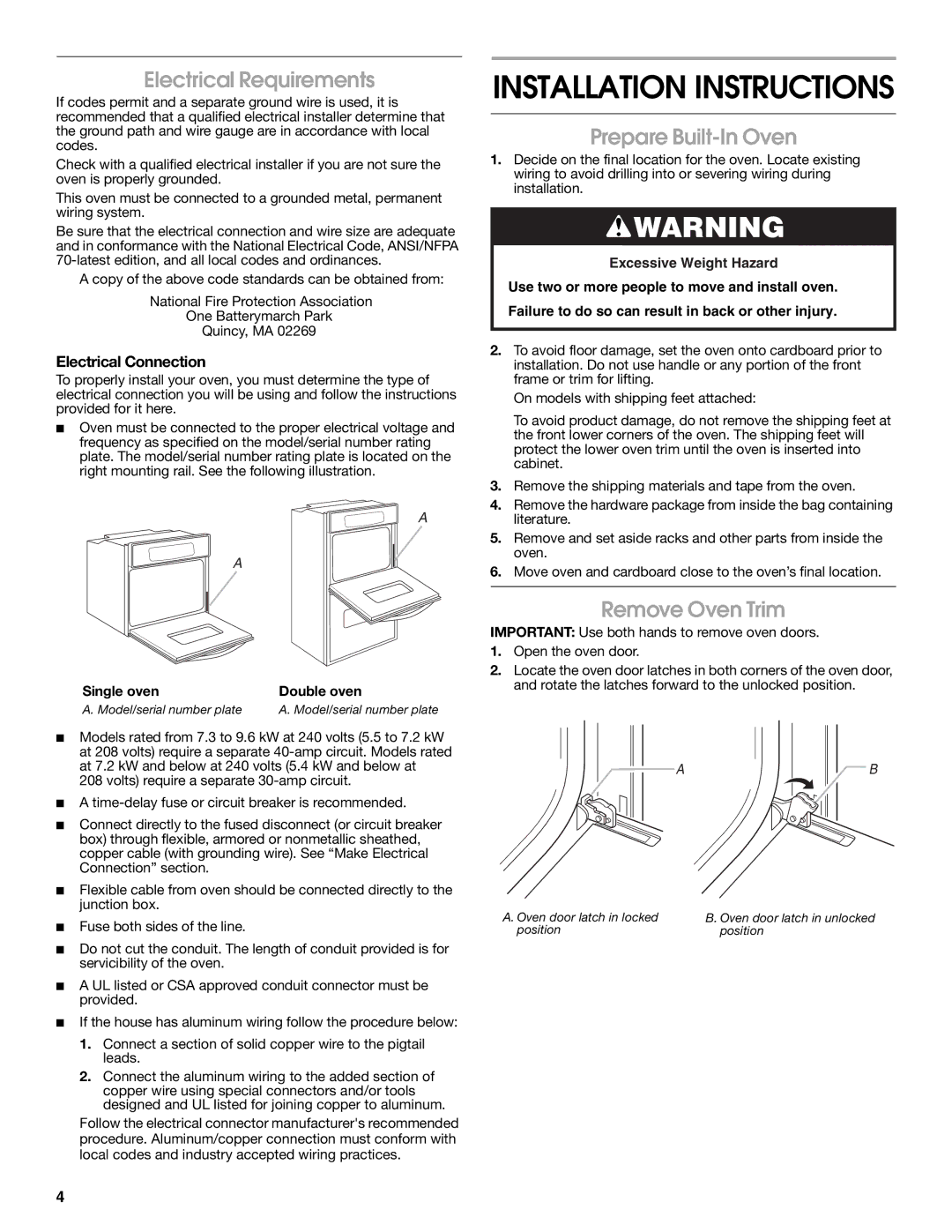

■Oven must be connected to the proper electrical voltage and frequency as specified on the model/serial number rating plate. The model/serial number rating plate is located on the right mounting rail. See the following illustration.

A

A

Single oven | Double oven |

A. Model/serial number plate | A. Model/serial number plate |

■Models rated from 7.3 to 9.6 kW at 240 volts (5.5 to 7.2 kW at 208 volts) require a separate

208volts) require a separate

■A

■Connect directly to the fused disconnect (or circuit breaker box) through flexible, armored or nonmetallic sheathed, copper cable (with grounding wire). See “Make Electrical Connection” section.

■Flexible cable from oven should be connected directly to the junction box.

■Fuse both sides of the line.

■Do not cut the conduit. The length of conduit provided is for servicibility of the oven.

■A UL listed or CSA approved conduit connector must be provided.

■If the house has aluminum wiring follow the procedure below:

1.Connect a section of solid copper wire to the pigtail leads.

2.Connect the aluminum wiring to the added section of copper wire using special connectors and/or tools designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's recommended procedure. Aluminum/copper connection must conform with local codes and industry accepted wiring practices.

INSTALLATION INSTRUCTIONS

Prepare Built-In Oven

1.Decide on the final location for the oven. Locate existing wiring to avoid drilling into or severing wiring during installation.

![]() WARNING

WARNING

Excessive Weight Hazard

Use two or more people to move and install oven. Failure to do so can result in back or other injury.

2.To avoid floor damage, set the oven onto cardboard prior to installation. Do not use handle or any portion of the front frame or trim for lifting.

On models with shipping feet attached:

To avoid product damage, do not remove the shipping feet at the front lower corners of the oven. The shipping feet will protect the lower oven trim until the oven is inserted into cabinet.

3.Remove the shipping materials and tape from the oven.

4.Remove the hardware package from inside the bag containing literature.

5.Remove and set aside racks and other parts from inside the oven.

6.Move oven and cardboard close to the oven’s final location.

Remove Oven Trim

IMPORTANT: Use both hands to remove oven doors.

1.Open the oven door.

2.Locate the oven door latches in both corners of the oven door, and rotate the latches forward to the unlocked position.

A | B |

A. Oven door latch in locked | B. Oven door latch in unlocked |

position | position |

4