3 REMOVING OLD THERMOSTAT

CONTINUED FROM FIRST PAGE

ATTENTION! This product contains mercury. There will not be any exposure to mercury under normal conditions of use. This product may replace a unit which contains mercury.

Do not open mercury cells. If a cell becomes damaged, do not touch any spilled mercury. Wearing

Mercury must not be discarded in household trash. When the unit this product is replacing is to be discarded, place in a suitable container and return to

4 MOUNTING AND WIRING

!WARNING

Do not use on circuits exceeding specified voltage. Higher voltage will damage control and could cause shock or fire hazard.

Do not short out terminals on gas valve or primary control to test. Short or incorrect wiring will damage thermostat and could cause personal injury and/or property damage.

Thermostat installation and all components of the sys- tem shall conform to Class II circuits per the NEC code.

Model 350 (Heating and Cooling):

A.Remove base from subbase: Loosen the three screws on the base and remove.

B.Mount switching subbase: Use the screws provided to mount the subbase to wall (see Fig. 1).

C.Attach wires to appropriate terminals:

•For two wire systems (Heat Only or Cool Only). If you have a

•If your system has more than two wires: Use the cross reference chart to determine correct wire connections. If you have a

•Electric heat or single stage heat pump systems:This thermostat is configured from the factory to operate a heat/ cool, fossil fuel (gas, oil, etc.) forced air system. It is configured correctly for any system that DOES NOT require the thermo- stat to energize the fan on a call for heat. If your system is an electric heat or

!CAUTION

Take care when securing and routing wires so they do not short to adjacent terminals or rear of thermostat. Personal injury and/or property damage may occur.

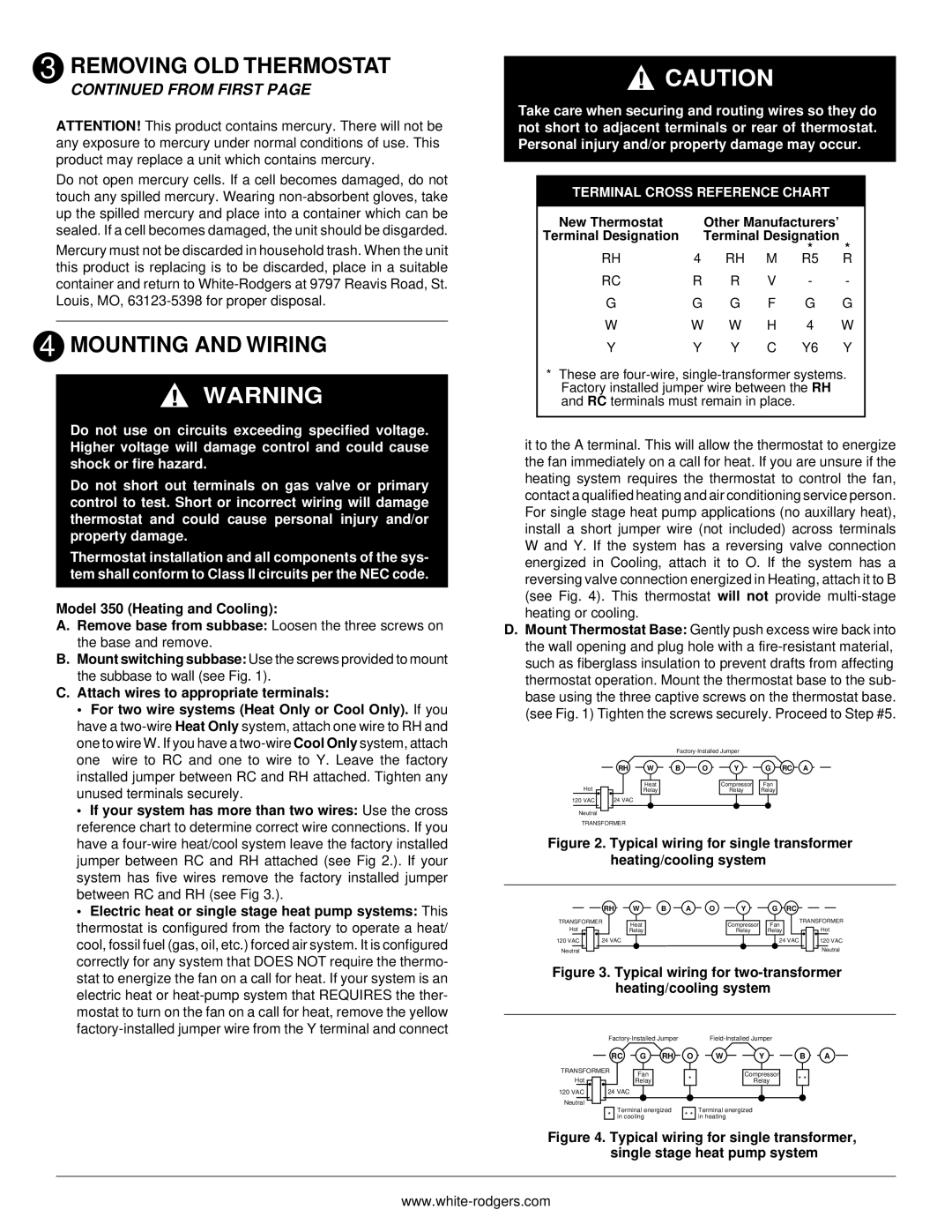

TERMINAL CROSS REFERENCE CHART

New Thermostat |

| Other Manufacturers’ |

| ||

Terminal Designation |

| Terminal Designation |

| ||

RH | 4 | RH | M | * | * |

R5 | R | ||||

RC | R | R | V | - | - |

G | G | G | F | G | G |

W | W | W | H | 4 | W |

Y | Y | Y | C | Y6 | Y |

*These are

it to the A terminal. This will allow the thermostat to energize the fan immediately on a call for heat. If you are unsure if the heating system requires the thermostat to control the fan, contact a qualified heating and air conditioning service person. For single stage heat pump applications (no auxillary heat), install a short jumper wire (not included) across terminals W and Y. If the system has a reversing valve connection energized in Cooling, attach it to O. If the system has a reversing valve connection energized in Heating, attach it to B (see Fig. 4). This thermostat will not provide

D.Mount Thermostat Base: Gently push excess wire back into the wall opening and plug hole with a

| RH | W | B | O | Y | G RC A |

Hot |

| Heat |

|

| Compressor | Fan |

| Relay |

|

| Relay | Relay | |

120 VAC | 24 VAC |

|

|

|

|

|

Neutral

TRANSFORMER

Figure 2. Typical wiring for single transformer heating/cooling system

| RH | W | B | A | O | Y | G RC |

|

TRANSFORMER | Heat |

|

|

| Compressor | Fan | TRANSFORMER | |

Hot |

|

|

|

| Hot | |||

| Relay |

|

|

| Relay | Relay | ||

120 VAC | 24 VAC |

|

|

|

|

| 24 VAC | 120 VAC |

Neutral |

|

|

|

|

|

|

| Neutral |

Figure 3. Typical wiring for two-transformer heating/cooling system

| RC | G | RH | O | W | Y | B | A |

TRANSFORMER | Fan |

|

|

| Compressor |

|

| |

Hot |

|

| * |

| * * |

| ||

| Relay |

|

| Relay |

| |||

120 VAC | 24 VAC |

|

|

|

|

|

|

|

Neutral |

|

|

|

|

|

|

|

|

| Terminal energized | * * | Terminal energized |

|

| |||

| * in cooling |

| in heating |

|

|

| ||