COMPACT ZONE VALVES

For use on systems up to 142 PSI

INSTALLATION INSTRUCTIONS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE IN- STALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURY AND/OR PROPERTY DAMAGE.

The compact zone valves are

DESCRIPTION

Flare Fittings

Available Separately

This compact zone valve is intended for use with a low voltage system; do not use this zone valve with a millivolt or line voltage system. If in doubt about whether your wiring is millivolt, line or low voltage, have it inspected by a qualified heating contractor or electrician.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes and ordinances.

PRECAUTIONS

![]() CAUTION

CAUTION

To prevent electrical shock and/or equipment damage, disconnect electric power to system at main fuse or circuit breaker box, until installation is complete.

![]() CAUTION

CAUTION

To prevent injuries from scalding always drain system before installing or removing valve. To avoid gear damage operate lever slowly.

![]() WARNING

WARNING

Do not use on circuits exceeding specified voltages. Higher voltages will damage control and could cause shock or fire hazard.

All guarantees are void if these specifications are exceeded.

SPECIFICATIONS

Maximum System Pressure: 142 PSI

Differential Across Valve: 20 PSI

Maximum Water Temperature: 230°F

Minimum Water Temperature: 41°F

Maximum Ambiant Temperature: 140°F

Approx. Time Cycle: 10 seconds from full close to full open; 4 seconds from full open to full close.

Electrical Rating:

Valve motor – 0.35A @ 25VAC, 50/60 Hz., 6 W nominal Auxiliary switch: 3.0A Max. @ 25VAC

Thermostat: Use

Flow Coefficient - Cv Rating: 1/2" valves – 3.5 Cv (3.0 Kv) 3/4" valves – 3.5 Cv (3.0 Kv)

1" valves – 3.5 Cv (3.0 Kv)

St. Louis, MO

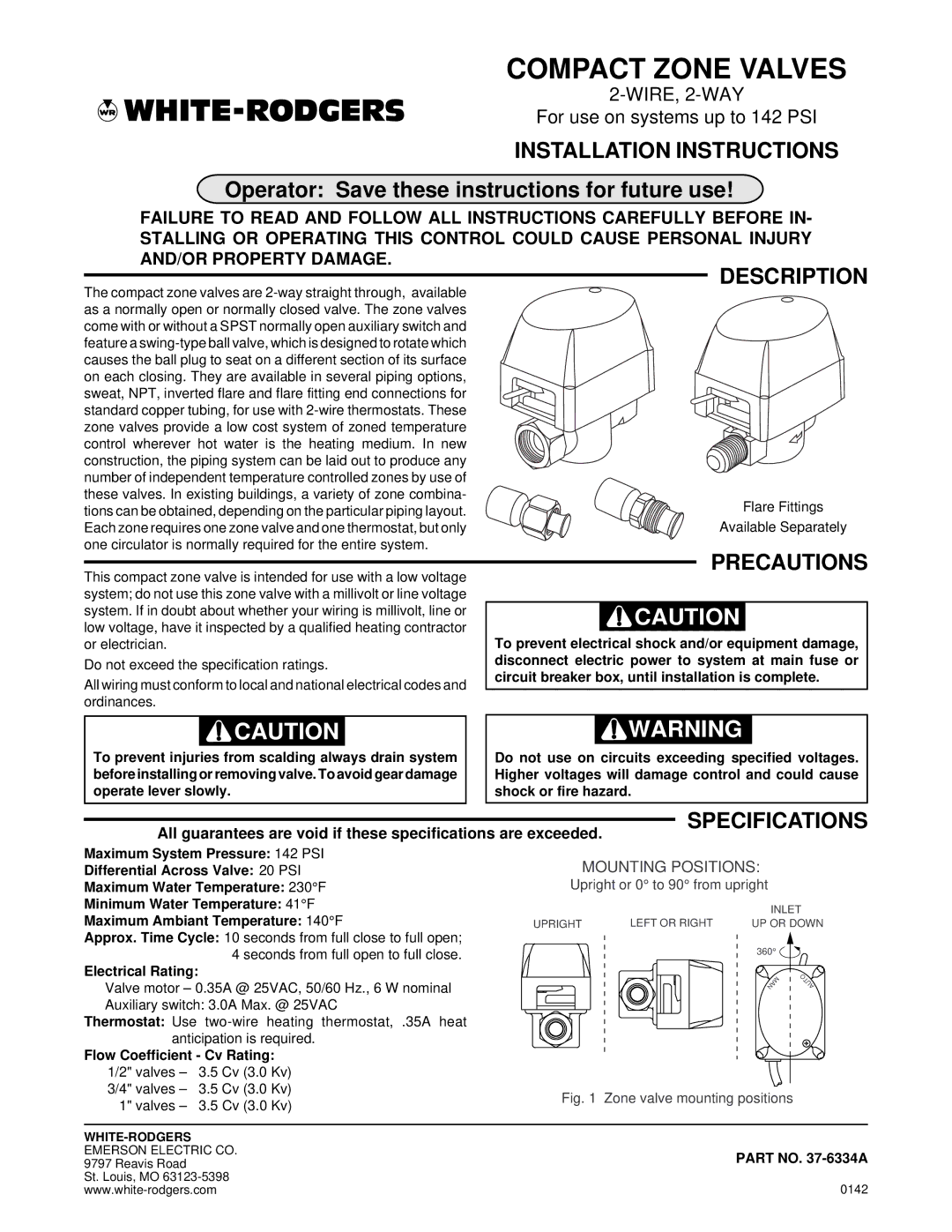

MOUNTING POSITIONS:

Upright or 0° to 90° from upright

|

| INLET | |

UPRIGHT | LEFT OR RIGHT | UP OR DOWN | |

|

| 360° |

|

|

| MAN | AUTO |

Fig. 1 Zone valve mounting positions

PART NO.

0142