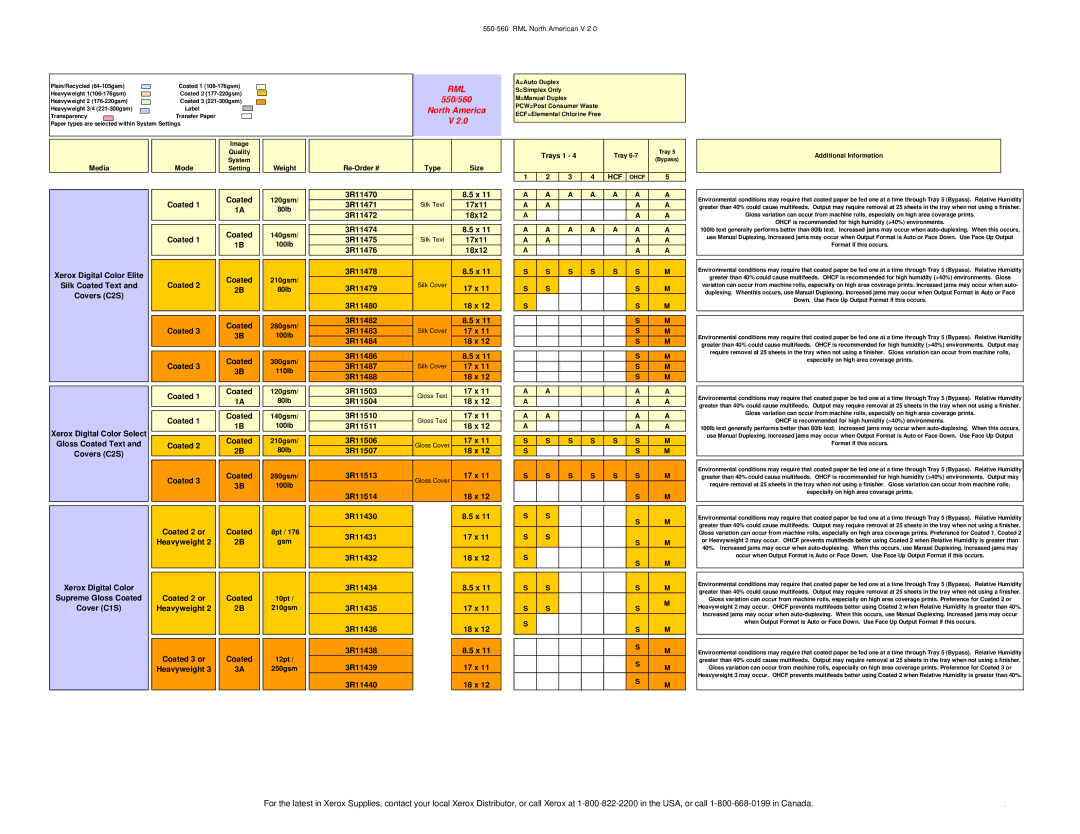

560, 550 specifications

The Xerox 016-1418-00, 016-1419-00, 016-1417-00, 016-1415-00, and 550 are a series of components designed to enhance efficiency and productivity in various printing and multifunctional devices. These products are specifically engineered to meet the diverse needs of modern offices and commercial environments, providing advanced technologies and impressive capabilities.The Xerox 016-1418-00 and 016-1419-00 components are recognized for their longevity and reliability. They serve critical roles in ensuring print quality and machine performance. These parts are typically associated with specific Xerox printers and multifunction devices, contributing to the seamless operation of equipment. Their design emphasizes compatibility with various Xerox products, ensuring that users receive optimal performance from their devices.

The 016-1417-00 and 016-1415-00 are essential components that focus on delivering high-quality output while maximizing the life of the machinery. These parts often include features such as enhanced precision engineering and durable materials, which aid in minimizing wear and tear during high-volume printing tasks. This focus on durability not only extends the lifespan of the devices but also ensures consistent output quality across long print runs.

The Xerox 550 is a multifunctional printing device known for its robust capabilities and versatility. Equipped with advanced printing technologies, the Xerox 550 can handle various tasks, including printing, copying, scanning, and faxing. Its high-speed performance is complemented by sophisticated controls that simplify user interaction, making it an ideal choice for busy office environments.

One of the standout features of the Xerox 550 is its capability to produce professional-quality prints at exceptional speeds. With advanced color management systems and high-resolution output, this device can meet the demands of high-quality document production, such as marketing materials and presentations. Additionally, its user-friendly interface and customizable settings allow for tailored operations that suit specific business needs.

In conclusion, the Xerox 016-1418-00, 016-1419-00, 016-1417-00, 016-1415-00, and the Xerox 550 showcase a commitment to cutting-edge technology and user-centric design. Together, they represent a comprehensive solution for modern printing and office needs, combining reliability, efficiency, and superior output quality to empower users in their daily tasks and operations.