∙To fix these fans through a wall you will need“Wall Vent Kit VK10”.

∙To fix these fans through a glass window or panel you will need

“Glass Mounting Kit GMK”

∙To fix these fans through a ceiling you will need "Ceiling Mounting Kit XCMK”.

∙A double pole isolating switch with a minimum contact gap of 3mm.

∙Suitably rated 3-core or 4-core cable.

∙A ceiling or wall on/off switch with built in indicator (DX180T/DX180H)

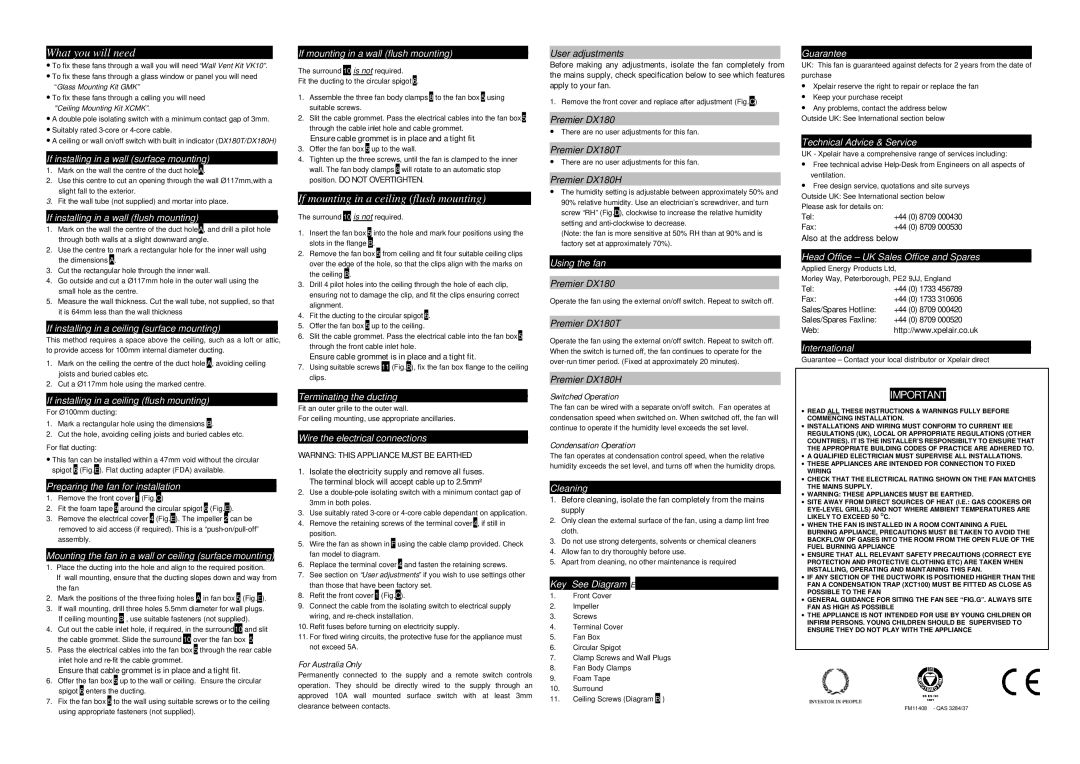

If installing in a wall (surface mounting) | ) |

1.Mark on the wall the centre of the duct hole .

.

2.Use this centre to cut an opening through the wall Ø117mm,with a slight fall to the exterior.

3.Fit the wall tube (not supplied) and mortar into place.

If installing in a wall (flush mounting)) | ) |

1.Mark on the wall the centre of the duct hole , and drill a pilot hole through both walls at a slight downward angle.

, and drill a pilot hole through both walls at a slight downward angle.

2.Use the centre to mark a rectangular hole for the inner wall using the dimensions  .

.

3.Cut the rectangular hole through the inner wall.

4.Go outside and cut a Ø117mm hole in the outer wall using the small hole as the centre.

5.Measure the wall thickness. Cut the wall tube, not supplied, so that it is 64mm less than the wall thickness

If installing in a ceiling (surface mounting) | ) |

This method requires a space above the ceiling, such as a loft or attic, to provide access for 100mm internal diameter ducting.

1.Mark on the ceiling the centre of the duct hole  , avoiding ceiling joists and buried cables etc.

, avoiding ceiling joists and buried cables etc.

2.Cut a Ø117mm hole using the marked centre.

If installing in a ceiling (flush mounting) | ) |

For Ø100mm ducting:

1.Mark a rectangular hole using the dimensions  .

.

2.Cut the hole, avoiding ceiling joists and buried cables etc.

For flat ducting:

∙This fan can be installed within a 47mm void without the circular spigot  (Fig.

(Fig. ). Flat ducting adapter (FDA) available.

). Flat ducting adapter (FDA) available.

Preparing the fan for installation | n |

1.Remove the front cover  (Fig.

(Fig. )

)

2.Fit the foam tape  around the circular spigot

around the circular spigot  (Fig.

(Fig. ).

).

3.Remove the electrical cover  (Fig.

(Fig. ). The impeller

). The impeller  can be removed to aid access (if required). This is a “push-on/pull-off” assembly.

can be removed to aid access (if required). This is a “push-on/pull-off” assembly.

Mounting the fan in a wall or ceiling (surface mounting)

1.Place the ducting into the hole and align to the required position.

If wall mounting, ensure that the ducting slopes down and way from the fan

2.Mark the positions of the three fixing holes  in fan box

in fan box  (Fig.

(Fig. ).

).

3.If wall mounting, drill three holes 5.5mm diameter for wall plugs. If ceiling mounting  , use suitable fasteners (not supplied).

, use suitable fasteners (not supplied).

4.Cut out the cable inlet hole, if required, in the surround and slit the cable grommet. Slide the surround

and slit the cable grommet. Slide the surround  over the fan box

over the fan box

5.Pass the electrical cables into the fan box  through the rear cable inlet hole and re-fit the cable grommet.

through the rear cable inlet hole and re-fit the cable grommet.

Ensure that cable grommet is in place and a tight fit.

6.Offer the fan box  up to the wall or ceiling. Ensure the circular spigot

up to the wall or ceiling. Ensure the circular spigot  enters the ducting.

enters the ducting.

7.Fix the fan box  to the wall using suitable screws or to the ceiling using appropriate fasteners (not supplied).

to the wall using suitable screws or to the ceiling using appropriate fasteners (not supplied).

If mounting in a wall (flush mounting) | ) |

The surround  is not required.

is not required.

Fit the ducting to the circular spigot  .

.

1.Assemble the three fan body clamps  to the fan box

to the fan box  using suitable screws.

using suitable screws.

2.Slit the cable grommet. Pass the electrical cables into the fan box through the cable inlet hole and cable grommet.

through the cable inlet hole and cable grommet.

Ensure cable grommet is in place and a tight fit.

3.Offer the fan box  up to the wall.

up to the wall.

4.Tighten up the three screws, until the fan is clamped to the inner wall. The fan body clamps  will rotate to an automatic stop position. DO NOT OVERTIGHTEN.

will rotate to an automatic stop position. DO NOT OVERTIGHTEN.

If mounting in a ceiling (flush mounting) | ) |

The surround  is not required.

is not required.

1.Insert the fan box  into the hole and mark four positions using the slots in the flange

into the hole and mark four positions using the slots in the flange  .

.

2.Remove the fan box  from ceiling and fit four suitable ceiling clips over the edge of the hole, so that the clips align with the marks on the ceiling

from ceiling and fit four suitable ceiling clips over the edge of the hole, so that the clips align with the marks on the ceiling  .

.

3.Drill 4 pilot holes into the ceiling through the hole of each clip, ensuring not to damage the clip, and fit the clips ensuring correct alignment.

4.Fit the ducting to the circular spigot  .

.

5.Offer the fan box  up to the ceiling.

up to the ceiling.

6.Slit the cable grommet. Pass the electrical cable into the fan box through the front cable inlet hole.

through the front cable inlet hole.

Ensure cable grommet is in place and a tight fit.

7.Using suitable screws  (Fig.

(Fig. ), fix the fan box flange to the ceiling clips.

), fix the fan box flange to the ceiling clips.

Terminating the ducting | g |

Fit an outer grille to the outer wall. | |

For ceiling mounting, use appropriate ancillaries. | |

| |

Wire the electrical connections | s |

WARNING: THIS APPLIANCE MUST BE EARTHED

1.Isolate the electricity supply and remove all fuses. The terminal block will accept cable up to 2.5mm²

2.Use a double-pole isolating switch with a minimum contact gap of 3mm in both poles.

3.Use suitably rated 3-core or 4-core cable dependant on application.

4.Remove the retaining screws of the terminal cover  , if still in position.

, if still in position.

5.Wire the fan as shown in  using the cable clamp provided. Check fan model to diagram.

using the cable clamp provided. Check fan model to diagram.

6.Replace the terminal cover  and fasten the retaining screws.

and fasten the retaining screws.

7.See section on “User adjustments” if you wish to use settings other than those that have been factory set.

8.Refit the front cover  (Fig.

(Fig. ).

).

9.Connect the cable from the isolating switch to electrical supply wiring, and re-check installation.

10.Refit fuses before turning on electricity supply.

11.For fixed wiring circuits, the protective fuse for the appliance must not exceed 5A.

For Australia Only

Permanently connected to the supply and a remote switch controls operation. They should be directly wired to the supply through an approved 10A wall mounted surface switch with at least 3mm clearance between contacts.

Before making any adjustments, isolate the fan completely from the mains supply, check specification below to see which features apply to your fan.

1. Remove the front cover and replace after adjustment (Fig. )

)

Premier DX180 | . |

∙ There are no user adjustments for this fan. | |

Premier DX180T | . |

∙There are no user adjustments for this fan.

∙The humidity setting is adjustable between approximately 50% and 90% relative humidity. Use an electrician’s screwdriver, and turn screw “RH” (Fig. ), clockwise to increase the relative humidity setting and anti-clockwise to decrease.

), clockwise to increase the relative humidity setting and anti-clockwise to decrease.

(Note: the fan is more sensitive at 50% RH than at 90% and is factory set at approximately 70%).

Using the fan | . |

| | |

Premier DX180 | . |

Operate the fan using the external on/off switch. Repeat to switch off.

Operate the fan using the external on/off switch. Repeat to switch off. When the switch is turned off, the fan continues to operate for the over-run timer period. (Fixed at approximately 20 minutes).

Switched Operation

The fan can be wired with a separate on/off switch. Fan operates at condensation speed when switched on. When switched off, the fan will continue to operate if the humidity level exceeds the set level.

Condensation Operation

The fan operates at condensation control speed, when the relative humidity exceeds the set level, and turns off when the humidity drops.

1.Before cleaning, isolate the fan completely from the mains supply

2.Only clean the external surface of the fan, using a damp lint free cloth.

3.Do not use strong detergents, solvents or chemical cleaners

4.Allow fan to dry thoroughly before use.

5.Apart from cleaning, no other maintenance is required

1.Front Cover

2.Impeller

3.Screws

4.Terminal Cover

5.Fan Box

6.Circular Spigot

7.Clamp Screws and Wall Plugs

8.Fan Body Clamps

9.Foam Tape

10.Surround

11.Ceiling Screws (Diagram  )

)

UK: This fan is guaranteed against defects for 2 years from the date of purchase

∙Xpelair reserve the right to repair or replace the fan

∙Keep your purchase receipt

∙Any problems, contact the address below

Outside UK: See International section below

Technical Advice & Service | e |

UK - Xpelair have a comprehensive range of services including:

∙Free technical advise Help-Desk from Engineers on all aspects of ventilation.

∙Free design service, quotations and site surveys

Outside UK: See International section below |

Please ask for details on: | |

Tel: | +44 (0) 8709 000430 |

Fax: | +44 (0) 8709 000530 |

Also at the address below |

Head Office – UK Sales Office and Spares | s |

Applied Energy Products Ltd, | | |

Morley Way, Peterborough, PE2 9JJ, England | | |

Tel: | +44 (0) 1733 456789 | | |

Fax: | +44 (0) 1733 310606 | | |

Sales/Spares Hotline: | +44 (0) 8709 000420 | | |

Sales/Spares Faxline: | +44 (0) 8709 000520 | | |

Web: | http://www.xpelair.co.uk | | |

| | | |

International | | s |

Guarantee – Contact your local distributor or Xpelair direct

IMPORTANT

∙READ ALL THESE INSTRUCTIONS & WARNINGS FULLY BEFORE COMMENCING INSTALLATION.

∙INSTALLATIONS AND WIRING MUST CONFORM TO CURRENT IEE REGULATIONS (UK), LOCAL OR APPROPRIATE REGULATIONS (OTHER COUNTRIES). IT IS THE INSTALLER’S RESPONSIBILTY TO ENSURE THAT THE APPROPRIATE BUILDING CODES OF PRACTICE ARE ADHERED TO.

∙A QUALIFIED ELECTRICIAN MUST SUPERVISE ALL INSTALLATIONS.

∙THESE APPLIANCES ARE INTENDED FOR CONNECTION TO FIXED WIRING

∙CHECK THAT THE ELECTRICAL RATING SHOWN ON THE FAN MATCHES THE MAINS SUPPLY.

∙WARNING: THESE APPLIANCES MUST BE EARTHED.

∙SITE AWAY FROM DIRECT SOURCES OF HEAT (I.E.: GAS COOKERS OR

EYE-LEVEL GRILLS) AND NOT WHERE AMBIENT TEMPERATURES ARE LIKELY TO EXCEED 50 OC.

∙WHEN THE FAN IS INSTALLED IN A ROOM CONTAINING A FUEL BURNING APPLIANCE, PRECAUTIONS MUST BE TAKEN TO AVOID THE BACKFLOW OF GASES INTO THE ROOM FROM THE OPEN FLUE OF THE FUEL BURNING APPLIANCE

∙ENSURE THAT ALL RELEVANT SAFETY PRECAUTIONS (CORRECT EYE PROTECTION AND PROTECTIVE CLOTHING ETC) ARE TAKEN WHEN INSTALLING, OPERATING AND MAINTAINING THIS FAN.

∙IF ANY SECTION OF THE DUCTWORK IS POSITIONED HIGHER THAN THE FAN A CONDENSATION TRAP (XCT100) MUST BE FITTED AS CLOSE AS POSSIBLE TO THE FAN

∙GENERAL GUIDANCE FOR SITING THE FAN SEE “FIG.G”. ALWAYS SITE FAN AS HIGH AS POSSIBLE

∙THE APPLIANCE IS NOT INTENDED FOR USE BY YOUNG CHILDREN OR INFIRM PERSONS. YOUNG CHILDREN SHOULD BE SUPERVISED TO ENSURE THEY DO NOT PLAY WITH THE APPLIANCE

FM11408 - QAS 3284/37