•Clean the exterior of engine and the entire tiller thoroughly. Lubricate the tiller as described in the lubrication instructions.

•We do not recommend the use of pressure washers to clean your unit. They may cause damage to electric components, spindles, pulleys, bearings or the engine. The use of pressure washers will result in shortened life and reduce serviceability.

•Refer to the engine manual for correct engine storage instructions.

•Wipe tines with oiled rag to prevent rust.

•Store tiller in a clean, dry area. Do not store next to corrosive materials, such as fertilizer.

NOTE: When storing any type of power equipment in an unventilated or metal storage shed, care should be taken to rustproof the equipment. Using a light oil or silicone, coat the equipment and especially any springs, bearings, and cables.

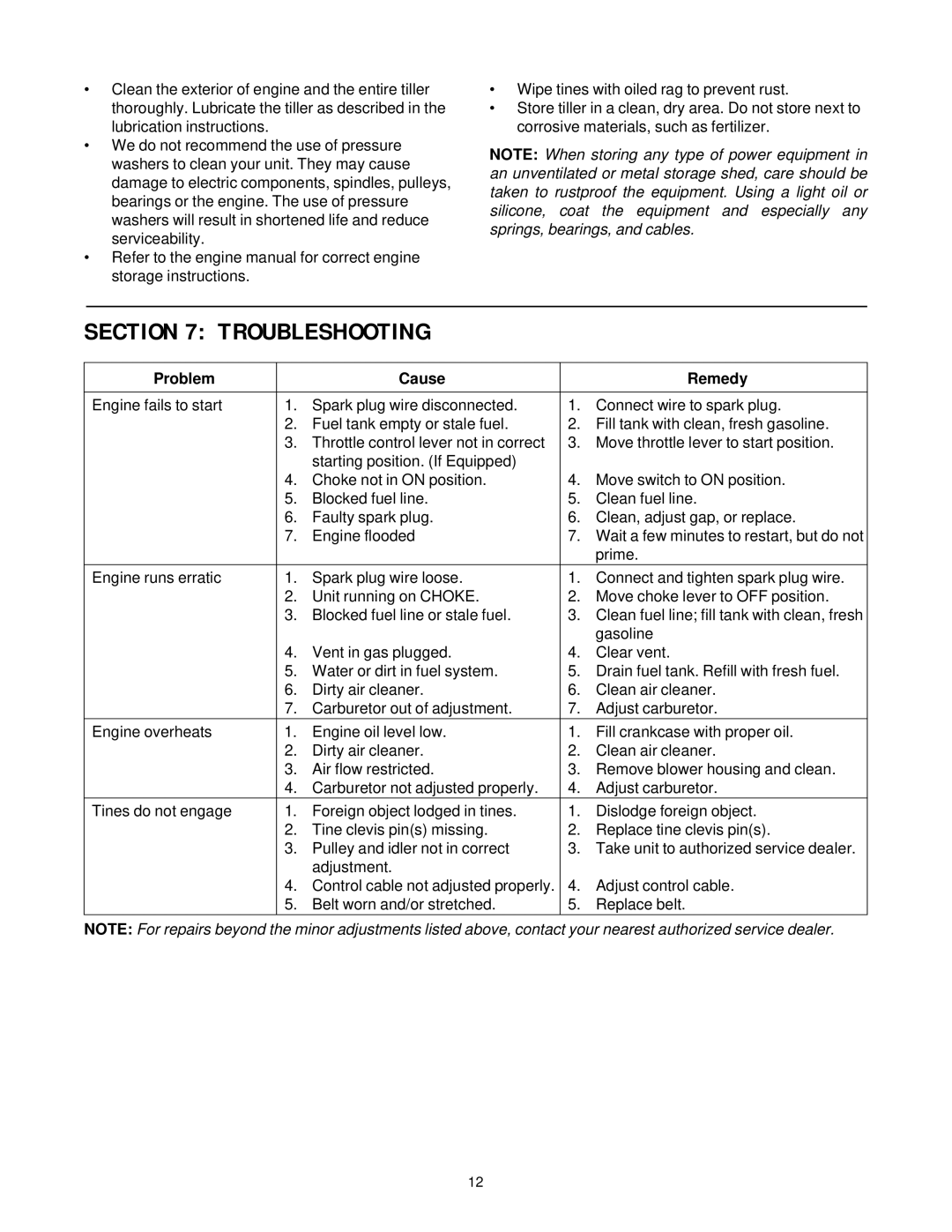

SECTION 7: TROUBLESHOOTING

Problem |

| Cause |

| Remedy |

|

|

|

|

|

Engine fails to start | 1. | Spark plug wire disconnected. | 1. | Connect wire to spark plug. |

| 2. | Fuel tank empty or stale fuel. | 2. | Fill tank with clean, fresh gasoline. |

| 3. | Throttle control lever not in correct | 3. | Move throttle lever to start position. |

|

| starting position. (If Equipped) |

|

|

| 4. | Choke not in ON position. | 4. | Move switch to ON position. |

| 5. | Blocked fuel line. | 5. | Clean fuel line. |

| 6. | Faulty spark plug. | 6. | Clean, adjust gap, or replace. |

| 7. | Engine flooded | 7. | Wait a few minutes to restart, but do not |

|

|

|

| prime. |

Engine runs erratic | 1. | Spark plug wire loose. | 1. | Connect and tighten spark plug wire. |

| 2. | Unit running on CHOKE. | 2. | Move choke lever to OFF position. |

| 3. | Blocked fuel line or stale fuel. | 3. | Clean fuel line; fill tank with clean, fresh |

|

|

|

| gasoline |

| 4. | Vent in gas plugged. | 4. | Clear vent. |

| 5. | Water or dirt in fuel system. | 5. | Drain fuel tank. Refill with fresh fuel. |

| 6. | Dirty air cleaner. | 6. | Clean air cleaner. |

| 7. | Carburetor out of adjustment. | 7. | Adjust carburetor. |

Engine overheats | 1. | Engine oil level low. | 1. | Fill crankcase with proper oil. |

| 2. | Dirty air cleaner. | 2. | Clean air cleaner. |

| 3. | Air flow restricted. | 3. | Remove blower housing and clean. |

| 4. | Carburetor not adjusted properly. | 4. | Adjust carburetor. |

Tines do not engage | 1. | Foreign object lodged in tines. | 1. | Dislodge foreign object. |

| 2. | Tine clevis pin(s) missing. | 2. | Replace tine clevis pin(s). |

| 3. | Pulley and idler not in correct | 3. | Take unit to authorized service dealer. |

|

| adjustment. |

|

|

| 4. | Control cable not adjusted properly. | 4. | Adjust control cable. |

| 5. | Belt worn and/or stretched. | 5. | Replace belt. |

NOTE: For repairs beyond the minor adjustments listed above, contact your nearest authorized service dealer.

12