RANGE

COMPOSITION

Chilling means bringing the temperature of cooked food from +90ºC to +3°C in a short time lap to minimize bacteria proliferation and avoid loss of food consistency and texture. The ZANUSSI easyChill Blast Chillers/Freezers reduce temperature to +3°C at food core in less than 90 minutes and down to

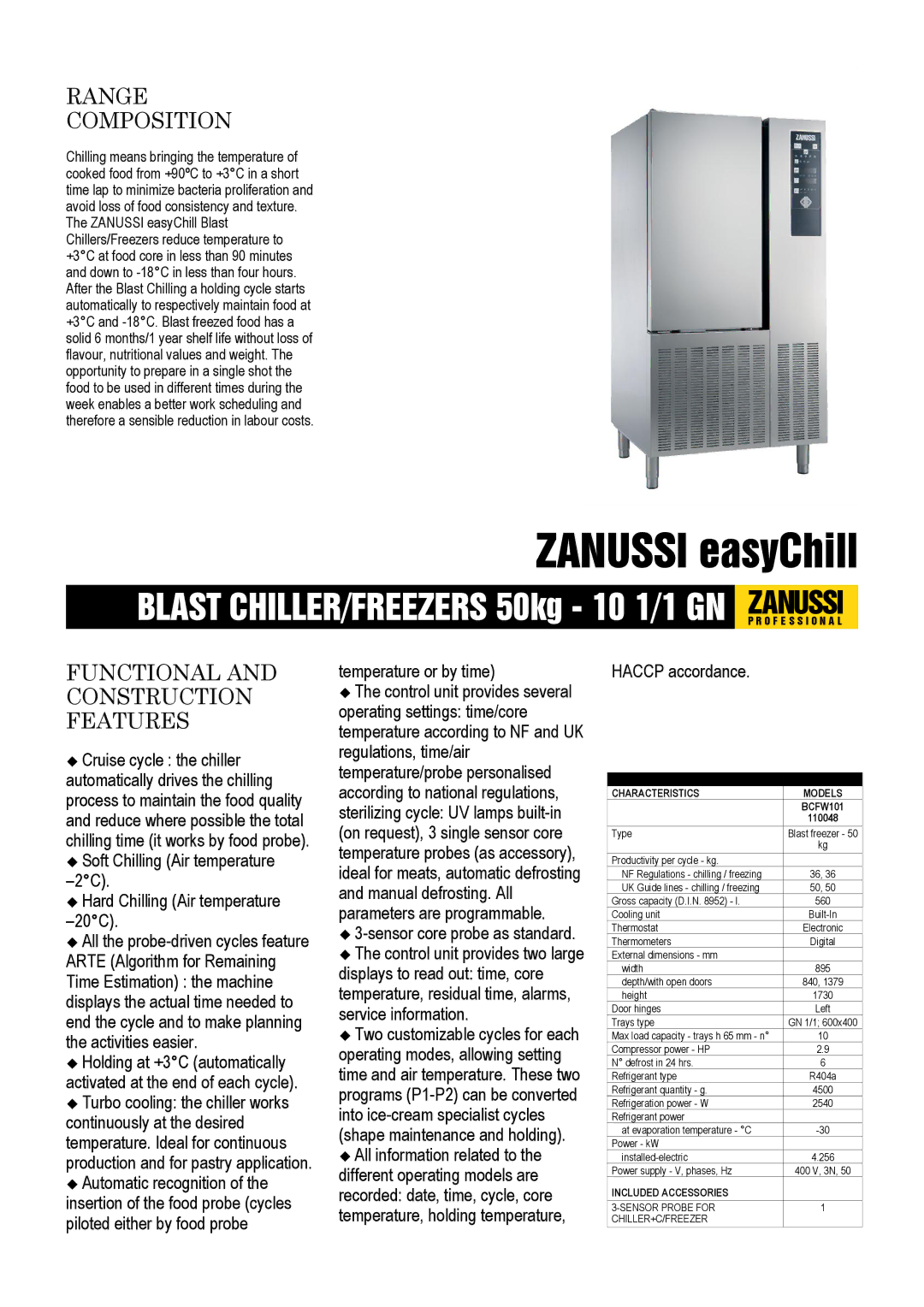

ZANUSSI easyChill

BLAST CHILLER/FREEZERS 50kg - 10 1/1 GN ZANUSSIP R O F E S S I O N A L

FUNCTIONAL AND CONSTRUCTION FEATURES

�Cruise cycle : the chiller automatically drives the chilling process to maintain the food quality and reduce where possible the total chilling time (it works by food probe).

�Soft Chilling (Air temperature

�Hard Chilling (Air temperature

�All the

�Holding at +3°C (automatically activated at the end of each cycle).

�Turbo cooling: the chiller works continuously at the desired temperature. Ideal for continuous production and for pastry application.

�Automatic recognition of the insertion of the food probe (cycles piloted either by food probe

temperature or by time)

�The control unit provides several operating settings: time/core temperature according to NF and UK regulations, time/air temperature/probe personalised according to national regulations, sterilizing cycle: UV lamps

�

�The control unit provides two large displays to read out: time, core temperature, residual time, alarms, service information.

�Two customizable cycles for each operating modes, allowing setting time and air temperature. These two programs

�All information related to the different operating models are recorded: date, time, cycle, core temperature, holding temperature,

HACCP accordance.

TECHNICAL DATA |

|

CHARACTERISTICS | MODELS |

| BCFW101 |

| 110048 |

Type | Blast freezer - 50 |

| kg |

Productivity per cycle - kg. |

|

NF Regulations - chilling / freezing | 36, 36 |

UK Guide lines - chilling / freezing | 50, 50 |

Gross capacity (D.I.N. 8952) - l. | 560 |

Cooling unit | |

Thermostat | Electronic |

Thermometers | Digital |

External dimensions - mm |

|

width | 895 |

depth/with open doors | 840, 1379 |

height | 1730 |

Door hinges | Left |

Trays type | GN 1/1; 600x400 |

Max load capacity - trays h 65 mm - n° | 10 |

Compressor power - HP | 2.9 |

N° defrost in 24 hrs. | 6 |

Refrigerant type | R404a |

Refrigerant quantity - g. | 4500 |

Refrigeration power - W | 2540 |

Refrigerant power |

|

at evaporation temperature - °C | |

Power - kW |

|

4.256 | |

Power supply - V, phases, Hz | 400 V, 3N, 50 |

INCLUDED ACCESSORIES |

|

1 | |

CHILLER+C/FREEZER |

|