9. Maintenance

![]()

![]() IMPORTANT

IMPORTANT

•Note that using any spark plug other than those des- ignated may result in the engine failing to operate prop- erly or in the engine becoming overheated and dam- aged.

•To install the spark plug, first turn the plug until it is finger tight, then tighten it a quarter turn more with a socket wrench.

87 ~ 104

TIGHTENING TORQUE: (9.8 ~ 11.8 N.m.)

MUFFLER

![]()

![]() WARNING

WARNING

•Inspect periodically, the muffler for loose fasteners, any damage or corrosion. If any sign of exhaust leak- age is found, stop using the machine and have it re- paired immediately.

•Note that failing to do so may result in the engine catching on fire.

SPARK ARRESTER

•The muffler is equipped with a spark arrester to pre- vent red hot carbon from flying out of the exhaust out- let. Periodically inspect and clean as necessary with a wire brush.

(1)Spark arrester

(1)

GEAR CASE

•The reduction gears are lubricated by multipurpose,

•Remove the bolt opposit to the grease nipple before installing new grease to arrange for old grease to exit.

INTAKE AIR COOLING VENT

![]()

![]() WARNING

WARNING

•Never touch the cylinder, muffler, or spark plugs with your bare hands immediately after stopping the engine. The engine can become very hot when in operation, and doing so could result in severe burns.

BCZ3000DL / BCZ3000DW

• | When checking the machine to make sure that it |

|

| is okay before using it, check the area around the |

|

| muffler and remove any wood chips or leaves |

|

| which have attached themselves to the |

|

| brushcutter. Failing to do so could cause the muf- | G |

| fler to become overheated and that in turn could | B |

| cause the engine to catch on fire. Always make |

|

| sure that the muffler is clean and free of wood |

|

| chips, leaves, and other waste before use. |

|

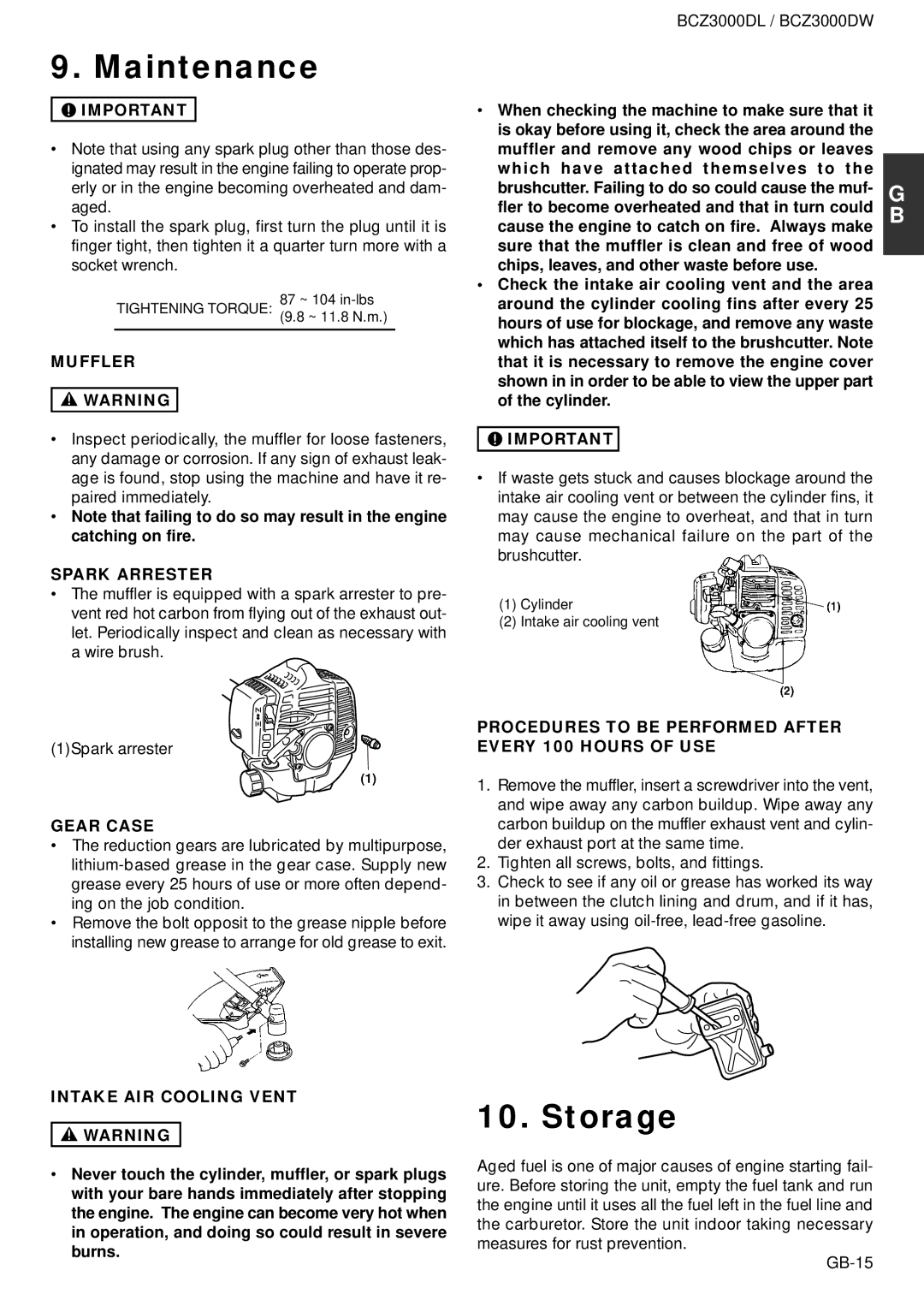

• | Check the intake air cooling vent and the area |

|

| around the cylinder cooling fins after every 25 |

|

| hours of use for blockage, and remove any waste |

|

| which has attached itself to the brushcutter. Note |

|

| that it is necessary to remove the engine cover |

|

| shown in in order to be able to view the upper part |

|

| of the cylinder. |

|

![]()

![]() IMPORTANT

IMPORTANT

•If waste gets stuck and causes blockage around the intake air cooling vent or between the cylinder fins, it may cause the engine to overheat, and that in turn may cause mechanical failure on the part of the brushcutter.

(1)Cylinder

(2)Intake air cooling vent

PROCEDURES TO BE PERFORMED AFTER EVERY 100 HOURS OF USE

1.Remove the muffler, insert a screwdriver into the vent, and wipe away any carbon buildup. Wipe away any carbon buildup on the muffler exhaust vent and cylin- der exhaust port at the same time.

2.Tighten all screws, bolts, and fittings.

3.Check to see if any oil or grease has worked its way in between the clutch lining and drum, and if it has, wipe it away using

10. Storage

Aged fuel is one of major causes of engine starting fail- ure. Before storing the unit, empty the fuel tank and run the engine until it uses all the fuel left in the fuel line and the carburetor. Store the unit indoor taking necessary measures for rust prevention.