G3800 specifications

The Zenoah G3800 is a highly regarded engine in the realm of small engines, particularly known for its robust performance and reliability. As a two-stroke gasoline engine, it offers a unique combination of power and efficiency, making it a favored choice for various applications, including lawn equipment, handheld tools, and recreational vehicles.One of the standout features of the Zenoah G3800 is its impressive power-to-weight ratio. Weighing approximately 4.1 kg (about 9 lbs), the engine delivers a substantial output of 38 cc, enabling it to perform admirably in demanding conditions. This balance of weight and power allows for greater maneuverability in tools such as chainsaws, trimmers, and blowers.

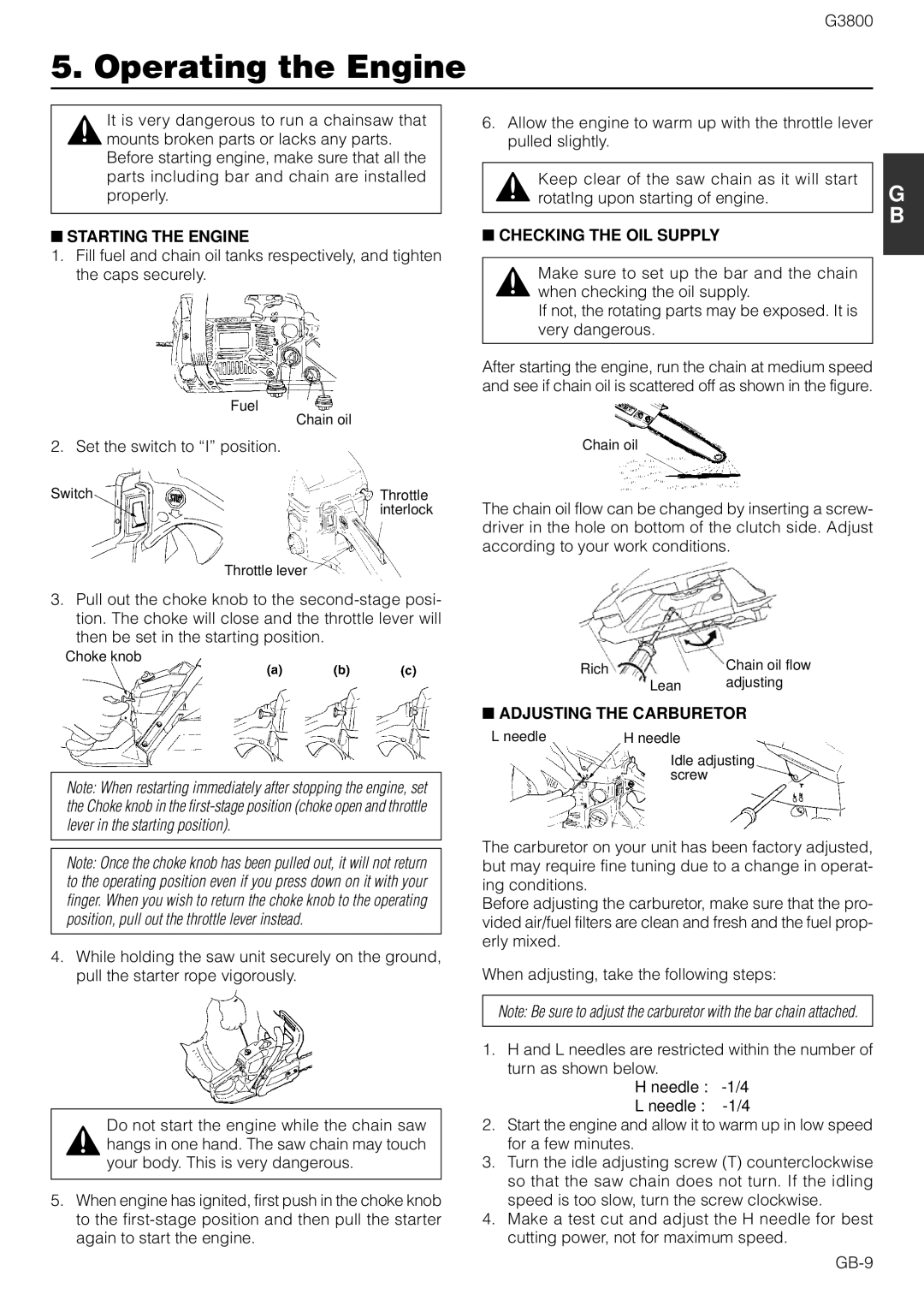

The G3800 is equipped with advanced technologies that enhance its overall performance and user experience. One notable innovation is its state-of-the-art ignition system, which ensures quick starts and smooth acceleration. The engine features a simple carburetion system that optimizes fuel delivery, ensuring that users get maximum power without sacrificing fuel efficiency.

Another characteristic that sets the G3800 apart is its durable construction. Made from high-quality materials, it is built to withstand the stresses associated with regular use in various environments. This durability not only extends the engine's lifespan but also minimizes maintenance needs, making it a practical choice for both everyday users and professionals.

Additionally, the Zenoah G3800 boasts low emissions thanks to its efficient combustion system. This feature aligns with modern environmental standards, making it a responsible choice for those who are mindful of their ecological footprint. The engine operates quietly, reducing noise pollution and providing a more pleasant working experience.

Overall, the Zenoah G3800 combines innovative technology, robust design, and environmental consideration, making it a standout engine in the small engine market. Whether for professional landscaping or DIY projects, its reliable performance and user-friendly characteristics make it an ideal choice for a wide range of applications.