TR2002 specifications

The Zenoah TR2002 is a powerful and versatile two-stroke engine that has garnered attention within the realm of professional outdoor power equipment. Designed primarily for use in handheld tools, such as brush cutters and trimmers, this engine exemplifies a perfect blend of efficiency, performance, and user-friendliness.One of the standout features of the Zenoah TR2002 is its lightweight design, which significantly enhances maneuverability during operation. Weighing considerably less than many competing models, the TR2002 allows users to work for extended periods without the frustrating fatigue that can be common with heavier equipment. This aspect is particularly appealing to both amateur gardeners and professional landscape contractors alike.

In terms of technology, the Zenoah TR2002 incorporates advanced two-stroke technology to deliver robust power output while maintaining impressive fuel efficiency. This engine is designed to minimize emissions, making it compliant with stringent environmental regulations. The TR2002 employs a unique scavenging system that ensures optimal fuel-air mixture, which translates to improved performance and reduced operational noise.

The durability of the Zenoah TR2002 cannot be overlooked. Constructed with high-quality materials, this engine is built to withstand the rigors of continuous fieldwork. Its robust design is complemented by an efficient cooling system that prevents overheating, which can be a common issue in high-performance engines.

Another defining characteristic of the Zenoah TR2002 is its user-friendly operation. The engine features easy starting technology, which minimizes the effort needed to kickstart the unit. Additionally, the ergonomic handle design enhances user comfort, enabling better control during use. This aspect is essential for achieving precision in landscaping tasks, where maneuverability and control are paramount.

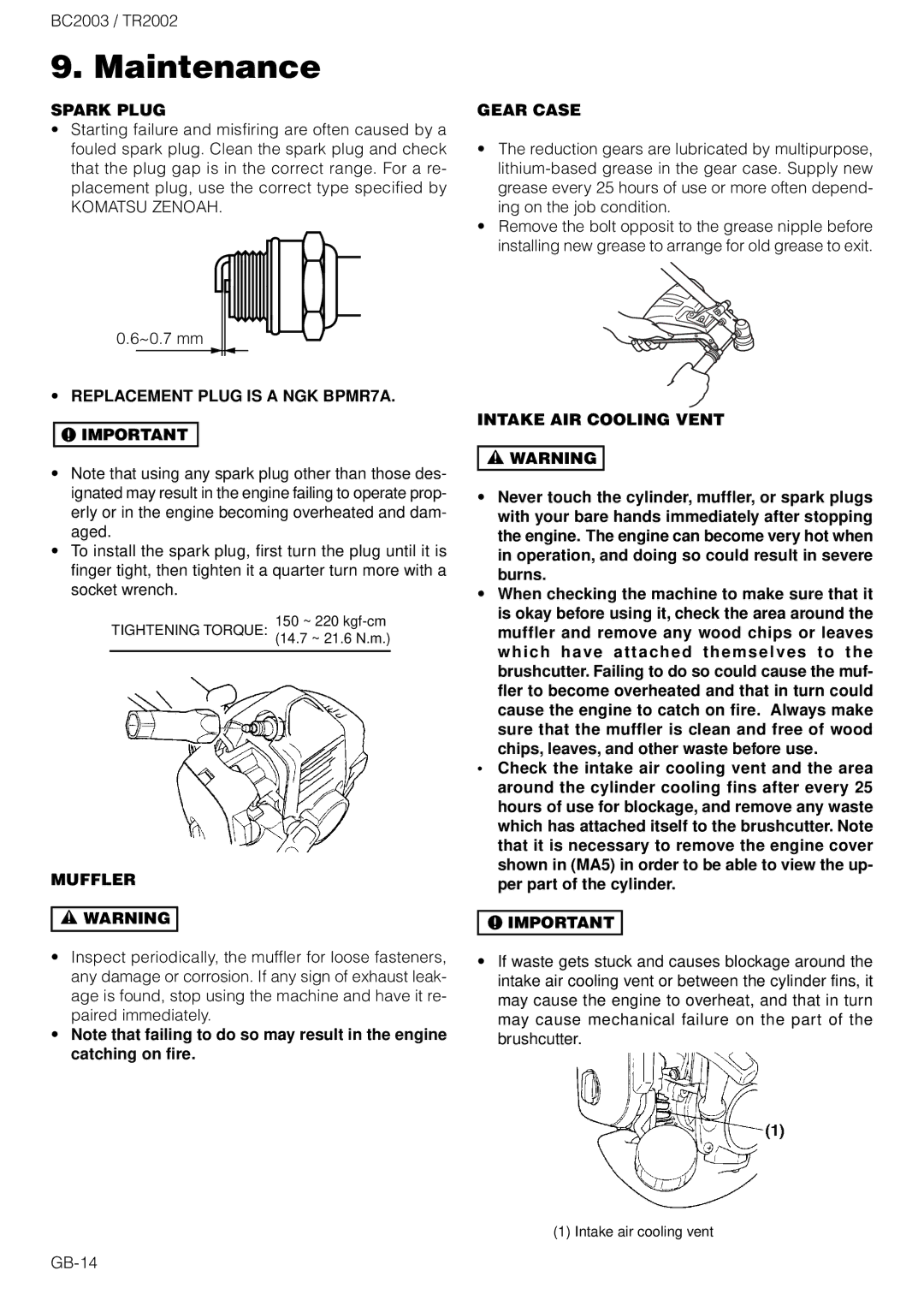

Maintenance is also simplified with the Zenoah TR2002. It is designed for easy access to the air filter and spark plug, allowing for quick and efficient servicing. This design consideration significantly reduces downtime and keeps the machine running smoothly.

In conclusion, the Zenoah TR2002 stands out as a well-rounded engine option for those in need of a reliable and efficient power source for their outdoor tools. Its combination of lightweight design, advanced technologies, durability, and user-friendly features make it a valuable asset for both professional landscapers and gardening enthusiasts. Whether tackling tough brush or fine trimming, the TR2002 delivers the performance needed to get the job done efficiently.