PSZ2460S

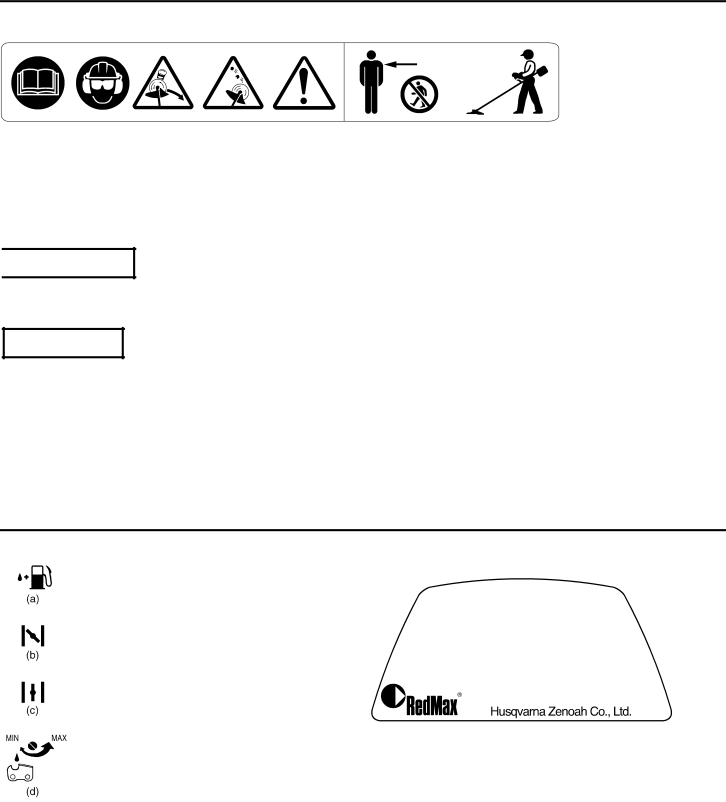

3. Warning labels on the machine

(1) | (2) | (3) | (4) | (5) | (6) |

|

|

|

|

| 15m (50ft) |

(1)Read owner's manual before operating this machine.

(2)Wear head, eye and ear protection.

(3)Warning! Danger of kickback.

(4)Beware of thrown objects.

(5)Warning/Attention

(6)Keep all children, bystanders and helpers 15 meters away from the brushcutter.

![]()

![]() IMPORTANT

IMPORTANT

If warning label peel off or become soiled and impossible to read, you should contact the dealer from which you purchased the product to order new labels and affix them in the required location(s).

![]() WARNING

WARNING

Never modify your brushcutter.

We won't warrant the machine, if you use the remodeled brushcutter or you don't observe the proper usage written in the manual.

4. Symbols on the machine

For safe operation and maintenance, symbols are carved in relief on the machine. According to these indications, please be careful not to take a mistake.

(a)The port to refuel the "MIX GASOLINE" Position: FUEL TANK CAP

(b)The direction to close the choke Position: AIR CLEANER COVER

(c)The direction to open the choke Position: AIR CLEANER COVER

(d)If you turn the rod by screwdriver follow the arrow to the "MAX" position, the chain oil flow more,

and if you turn to the "MIN" position, less. Position: Bottom of the power unit

■EMISSION CONTROL

An emission control label is located on the engine.

EMISSION CONTROL INFORMATION

THIS ENGINE MEETS U.S. EPA AND CALI-

FORNIA EXH / EVP REGS FOR 2010*1 S.O.R.E.

ENGINE FAMILY : AHQZS.0244BV*2 DISPL.: 24cc

EMISSION CONTROL SYSTEM : EXH;EM/EVP;SP*3

COMPLIANCE PERIOD : 300 HOURS

REFER TO OPERATOR'S MANUAL FOR MAINTE- NANCE, SPECIFICATIONS AND ADJUSTMENTS.

MANUFACTURED:

USE JASO FD OR ISO L-EGD GRADE 50:1 OIL

*1: The year will be changed every year of manufacturing.

*2: The initial will be changed every year of manufacturing.

*3: SP : Sealed tank made of HDPE or PE.